Polycarboxylic acid water reducer for finish concrete and preparation method of water reducer

The technology of fair-faced concrete and polycarboxylic acid series is applied in the field of concrete admixtures, which can solve the problems of loss of initial workability of fresh concrete, severe delamination of concrete appearance, and influence on concrete construction quality, etc., and achieves good encapsulation and no solvent. Simple and common effects of poisoning and reacting raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

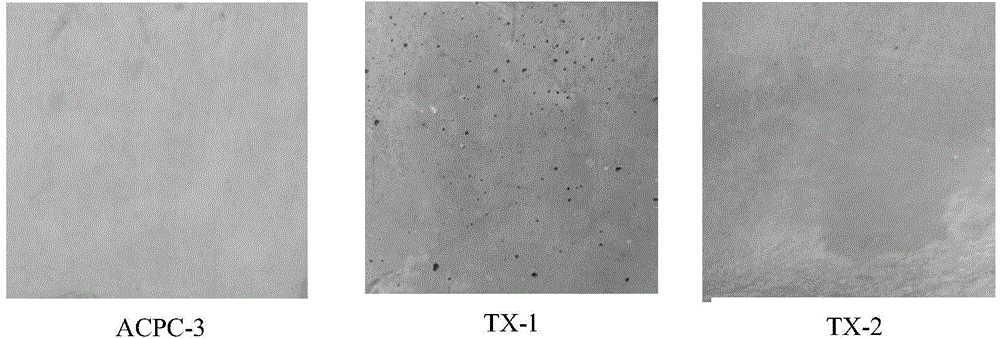

Image

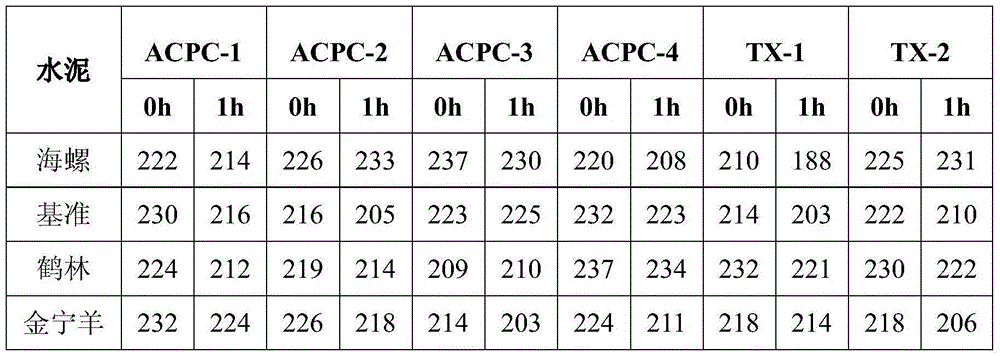

Examples

Embodiment 1

[0030] 1) Add 103 grams of diethylenetriamine and 55 grams of water to a 500 mL four-necked flask equipped with a stirrer, thermometer and water separator, and add 103 grams of maleic anhydride and 1.5 grams of p-toluenesulfonic acid in five times within 1 hour ;

[0031] 2) Heat up to 90°C and continue stirring for 0.5h, then continue to heat up to 110°C-120°C and keep warm for 2h-5h until the water in the solution evaporates to dryness;

[0032] 3) Cool down to 60°C and add 170 grams of water to prepare a bright red viscous prepolymer solution (PP-1);

[0033] 4) Add 200 grams of hydroxybutyl vinyl polyoxyethylene ether (molecular weight is 2000), 23.8 grams of PP-1, 6.3 grams of sodium methacrylate and 120 grams of water in a four-necked flask equipped with a stirrer and a thermometer, Heat up to 45°C to 50°C, add 1.9 grams of 30% hydrogen peroxide and stir for 15 minutes, add 23.8 grams of acrylic acid, 0.7 grams of sodium formaldehyde sulfoxylate and 1.1 grams of 3-merca...

Embodiment 2

[0036] 1) Add 103 grams of diethylenetriamine and 55 grams of water to a 500 mL four-necked flask equipped with a stirrer, thermometer and water separator, and add 98 grams of maleic anhydride and 1.8 grams of sulfamic acid in five times within 1 hour;

[0037] 2) Heat up to 90°C and continue stirring for 0.5h, then continue to heat up to 110°C-120°C and keep warm for 2h-5h until the water in the solution evaporates to dryness;

[0038] 3) Cool down to 60°C and add 165 grams of water to prepare a bright red viscous prepolymer solution (PP-2);

[0039] 4) Add 200 grams of methylbutenyl polyoxyethylene ether (molecular weight is 2400), 19.2 grams of PP-2, 5.2 grams of 2-acrylamide-2-methylpropanesulfonate into a four-necked flask equipped with a stirrer and a thermometer Acid and 120 grams of water, heated to 45 ℃ ~ 50 ℃, add 1.8 grams of 30% hydrogen peroxide and stir for 15 minutes, 22.9 grams of methacrylic acid, 0.8 grams of L-ascorbic acid and 0.9 grams of mercaptoethanol p...

Embodiment 3

[0042] 1) Add 108 grams of diethylenetriamine and 55 grams of water to a 500 mL four-necked flask equipped with a stirrer, thermometer and water separator, and add 98 grams of maleic anhydride and 1.9 grams of p-toluenesulfonic acid in five times within 1 hour ;

[0043] 2) Heat up to 90°C and continue stirring for 0.5h, then continue to heat up to 110°C-120°C and keep warm for 2h-5h until the water in the solution evaporates to dryness;

[0044] 3) Cool down to 60°C and add 165 grams of water to prepare a bright red viscous prepolymer solution (PP-3);

[0045] 4) Add 200 grams of methylbutenyl polyoxyethylene ether (molecular weight is 3200), 10.4 grams of PP-3, 4.9 grams of sodium methacrylate and 120 grams of water in a four-necked flask equipped with a stirrer and a thermometer, Heat up to 45°C-50°C, add 1.7g of 30% hydrogen peroxide and stir for 15min, mix 15.8g of acrylic acid, 1.0g of sodium formaldehyde sulfoxylate and 1.0g of thioglycolic acid with 118g of water to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com