Method for synthesizing porous NaY molecular sieve microspheres

A molecular sieve and microsphere technology, which is applied in the directions of fajhedral crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., can solve the problems of carbon deposition, catalyst deactivation, etc. Simple and easy-to-control process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This example illustrates the steps and results of carbon sphere synthesis.

[0035] First, configure 100mL of 0.7mol / L starch solution, stir well until the solution is clear, put it into a 150mL hydrothermal reaction kettle with a polytetrafluoroethylene lining, seal it, and conduct a hydrothermal reaction in an oven at 200°C for 12h, then cool it naturally, 15000r / min centrifugation, the black carbon material was washed and centrifuged three times with purified water and ethanol respectively, and the final carbon material was obtained, which was dried in an oven at 80°C to obtain the carbon sphere material.

[0036] The SEM spectrum of the carbon sphere material is attached figure 1 shown. It can be found that the size of carbon spheres is evenly distributed in the range of 2-4mm.

Embodiment 2

[0038] This example illustrates the specific method for synthesizing molecular sieve microsphere materials.

[0039] First take 15.8g of sodium hydroxide and dissolve in 58g of water. After stirring well, add 13.3g Al 2 (SO4) 3 18H 2 O and 60g of silica sol with a mass fraction of 30 wt%, and finally Na 2 O: Al 2 o 3 :SiO2 2 :H 2 O molar ratio is 10:1:15:300.

[0040] Add 0.5g of the carbon spheres described in Example 1 in the above mixed solution. The final solution was ultrasonically crushed for 10 minutes and stirred vigorously for 4 hours to form a gel-like substance. It was aged for 12 hours and crystallized in a 150 mL polytetrafluoro-lined hydrothermal reactor at 100°C for 72 hours. After the end, it was naturally cooled, filtered and washed until pH= 8-9, dried and calcined at 500°C for 5 h to obtain NaY molecular sieve microspheres with a crystallinity of 99.7%.

Embodiment 3

[0042] This example illustrates the synthesis results of NaY molecular sieve microspheres.

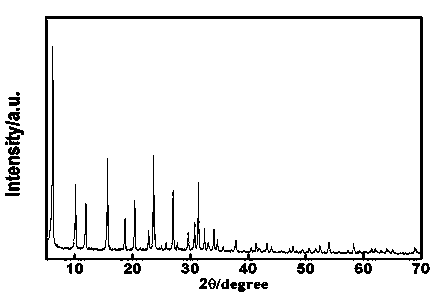

[0043] Get the NaY molecular sieve microsphere gained in embodiment 2, adopt X-ray pattern analysis, its result is as follows figure 2 shown. The results show that the material has the characteristic peak of NaY molecular sieve.

[0044] Get the obtained NaY molecular sieve microsphere of embodiment 2, adopt scanning electron microscope to analyze its microsphere size, its result is as follows image 3 shown. The results showed that the microspheres were 3-5 mm in size.

[0045] The NaY molecular sieve microspheres obtained in Example 2 were taken, and the specific surface area and pore characteristics of the microsphere materials were analyzed by adsorption method. The analytical instrument is a Micromeritics ASAP 2020 adsorption instrument, and the analysis temperature is 77K. The result is as Figure 4 shown. The results show that the material has abundant mesoporous structure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| mesopore | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com