Phytic acid doped carbon nitride-polyaniline nano composite material and preparation method thereof as well as intumescent fire retardant coating and preparation method thereof

A nanocomposite material and fireproof coating technology, applied in the field of intumescent fireproof coating and its preparation, phytic acid doped carbon nitride-polyaniline nanocomposite material and its preparation field, to improve flame retardancy, improve flame retardancy efficiency, The synthesis process is simple and easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The invention provides a preparation method of phytic acid doped carbon nitride-polyaniline nanocomposite material, comprising the following steps:

[0041] (1) mixing flake carbon nitride with a phytic acid solution to obtain a carbon nitride dispersion;

[0042] (2) Add aniline to the carbon nitride dispersion to obtain solution A;

[0043] (3) Ammonium persulfate is mixed with phytic acid solution to obtain solution B;

[0044] (4) The solution B is mixed with the solution A and reacted to obtain a phytic acid-doped carbon nitride-polyaniline nanocomposite material.

[0045] In the present invention, the particle size distribution of the flaky carbon nitride is preferably 0.2-5 μm, more preferably 0.2-2 μm; the concentration of phytic acid in the steps (1) and (3) is independently 0.4-0.6 mol / L.

[0046] In the present invention, in steps (1) and (3), the concentration of the phytic acid solution used is independently preferably 0.4 to 0.6 mol / L, and further inde...

Embodiment 1

[0065] Put 30g of melamine into the crucible, put the lid on and put it into the muffle furnace, raise the temperature at a rate of 10°C / min, heat it up to 550°C, keep it for 3 hours, cool it down to room temperature, and take it out to get a light yellow graphite phase Lumpy carbon nitride. Then put it into an uncovered crucible, put it into a muffle furnace, and raise the temperature at a rate of 10°C / min. After the temperature rises to 550°C, it is kept for 3 hours. After cooling down to room temperature naturally, it is taken out to obtain dark yellow nitrogen after thermal stripping. carbonized solids. Afterwards, the obtained yellow solid is put into a ball mill for ball milling to obtain carbon nitride nanosheets with a particle size of 0.2-2 μm.

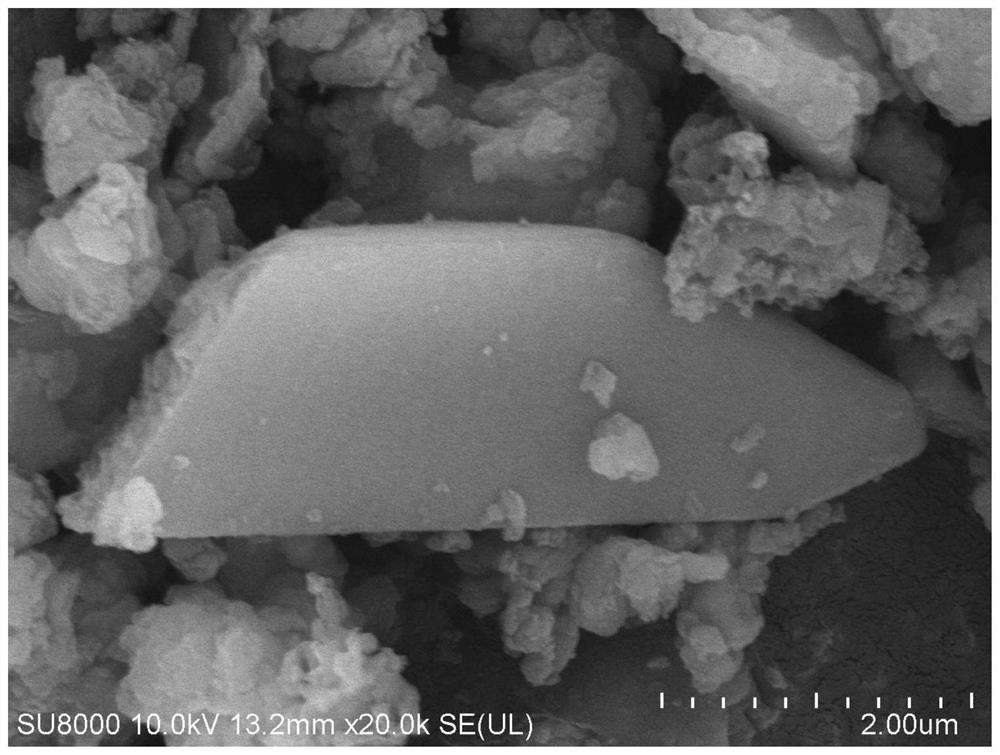

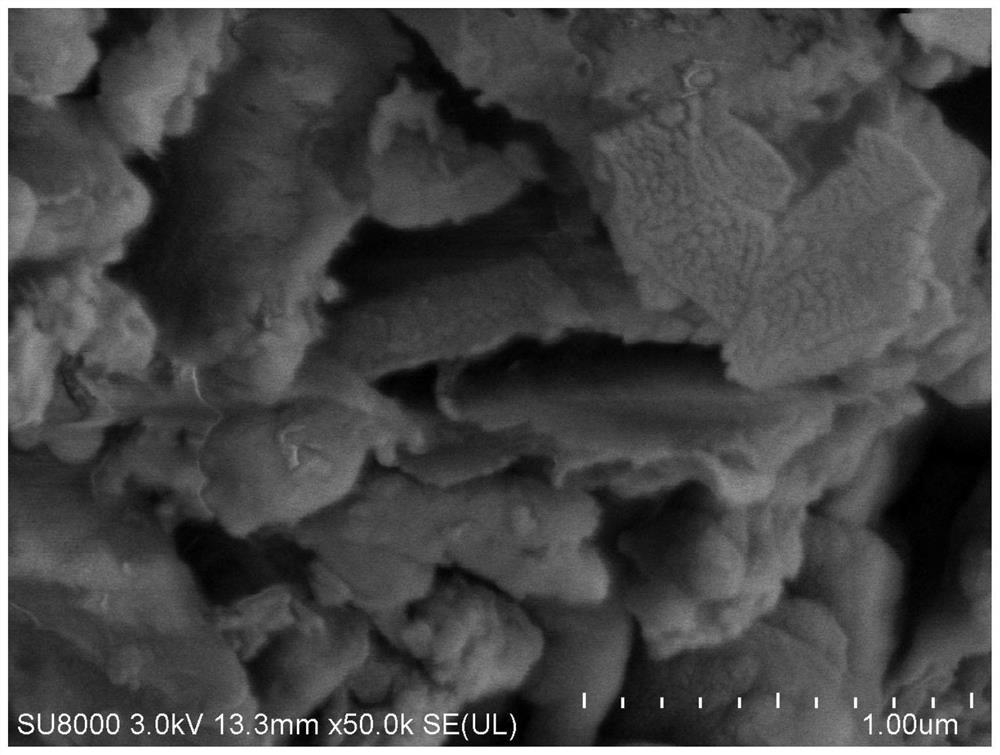

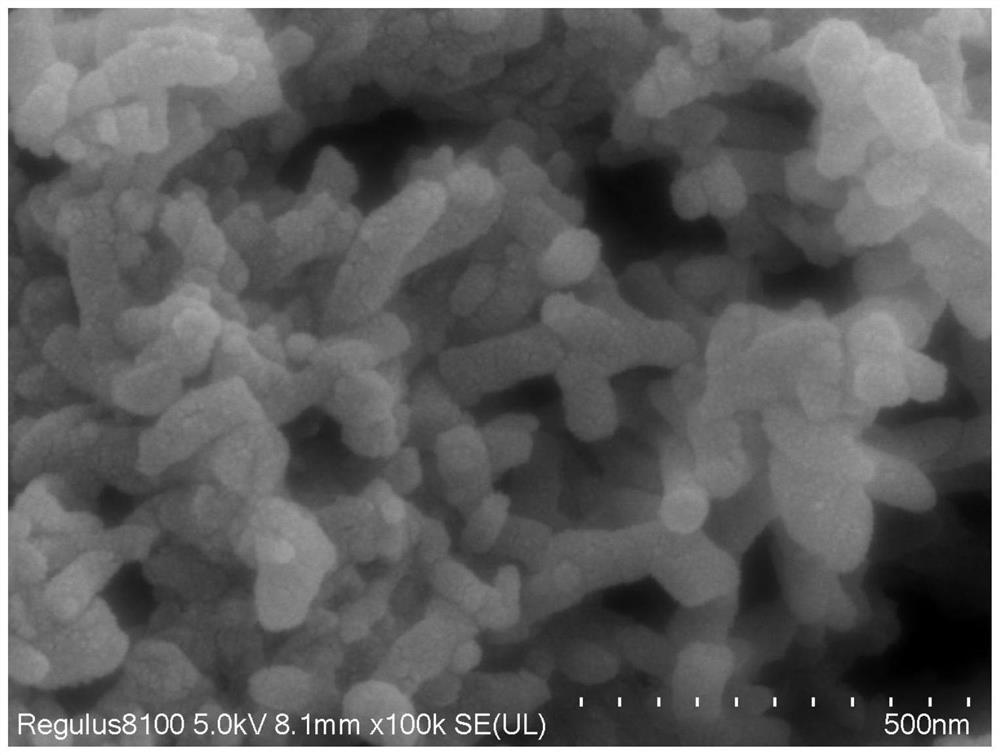

[0066] Characterize the obtained carbon nitride, the result is as follows Figure 1~2 shown by figure 1 It can be seen that the morphology of the obtained massive carbon nitride is a stacked block with a diameter of more t...

Embodiment 2

[0072] Put 30g of melamine into the crucible, put the lid on and put it into the muffle furnace, raise the temperature at a rate of 16°C / min, heat it up to 530°C, keep it for 3 hours, cool it down to room temperature, and take it out to get a light yellow graphite phase Lumpy carbon nitride. Then put it into an uncovered crucible, put it into a muffle furnace, heat up at a heating rate of 16°C / min, heat it up to 530°C, keep it for 3 hours, cool it down to room temperature naturally, and take it out to get dark yellow nitrogen after thermal stripping. carbonized solids. Afterwards, the obtained yellow solid is put into a ball mill for ball milling to obtain carbon nitride nanosheets with a particle size of 0.2-3 μm.

[0073] Take 0.2 g of the obtained carbon nitride nanosheets in 50 ml of 0.4 mol / L phytic acid solution, stir evenly, ultrasonically disperse for 20 min, and then add 3 g of aniline to obtain solution A.

[0074] Take 3g of ammonium persulfate in another 50ml 0.4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com