Polyimide humidity-sensitive material and preparation method thereof

A polyimide moisture-sensitive material and polyimide moisture-sensitive technology are applied in the analysis of materials, material capacitance, and material analysis through electromagnetic means, which can solve the problems of hysteresis, large nonlinear output, poor hydrolysis resistance, Prone to degradation and other problems, to achieve the effects of improving stability, reducing adsorption, and increasing moisture absorption/dehumidification speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

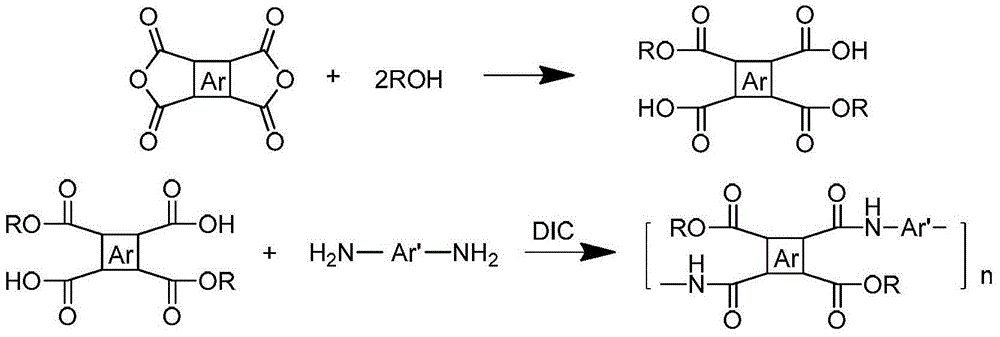

[0023] Specific Embodiment 1: A polyimide moisture-sensitive material of this embodiment, a polyimide moisture-sensitive material is firstly made of dianhydride, diamine, alcohol reagent, N,N'-diisopropyl carbon Diimine condensing agent, strong polar non-protonated solvent A and strong polar non-protonated solvent B are prepared to obtain polyamide ester powder, then polyamide ester powder is mixed with strong polar non-protonated solvent C, and solidified to obtain;

[0024] The molar ratio of the dianhydride to diamine is 1:(0.85~1.1); the mass ratio of the dianhydride to alcohol reagent is 1:(3~15); the dianhydride to N,N The molar ratio of '-diisopropylcarbodiimide condensing agent is 1:(1~10); the mass ratio of described dianhydride and strongly polar aprotonated solvent A is 1:(1~5); The mass ratio of the dianhydride to the strongly polar aprotonated solvent B is 1:(1~10); the mass ratio of the polyamide ester powder to the strongly polar aprotonated solvent C is 1:(1.5 ...

specific Embodiment approach 2

[0030] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the polyamide ester powder is specifically prepared according to the following steps: at room temperature, dianhydride is added to the alcohol reagent, and then at a temperature of Reflux at 78°C to 80°C for 1h to 12h, cool naturally to room temperature to obtain the diacid diester, place the diacid diester in an ice-water bath at a temperature of 1°C to 8°C to obtain a reaction system; dissolve the diamine In a strongly polar aprotic solvent A, a mixture A is obtained, and the N,N'-diisopropylcarbodiimide condensing agent is dissolved in a strongly polar aprotic solvent B to obtain a mixture B, at a temperature of In an ice-water bath at 1°C-8°C, first add mixture A to the reaction system, then add mixture B dropwise to the reaction system within 30min-60min, stir for 1h-2h, remove the ice-water bath, and then stir at room temperature React for 5h to 24h to obtain a reaction...

specific Embodiment approach 3

[0032] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that: the alcohol reagent is methanol or ethanol. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com