Method for splitting pectin with high esterification degree to prepare monosaccharide and oligogalacturonic acid employing pectinase

A technology of galacto-oligosaccharides and pectinase, applied in biochemical equipment and methods, methods based on microorganisms, lyase, etc., can solve the problems of low utilization efficiency and failure to obtain the degree of polymerization of monosaccharides and disaccharides , to achieve the effect of low cost, high enzyme utilization efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

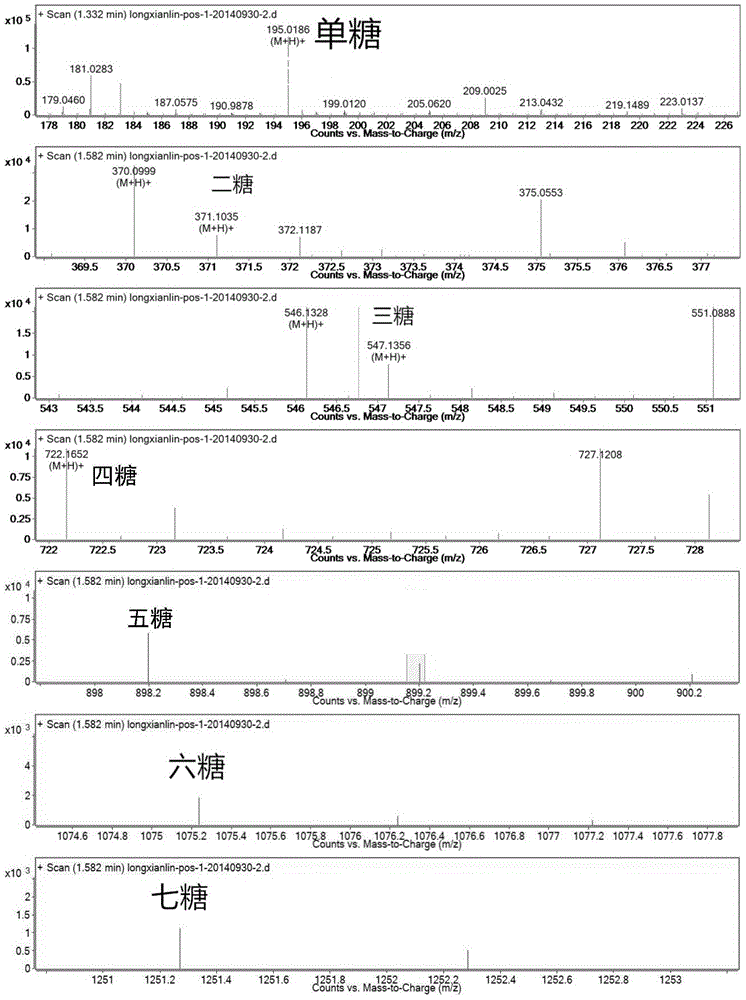

Image

Examples

Embodiment 1

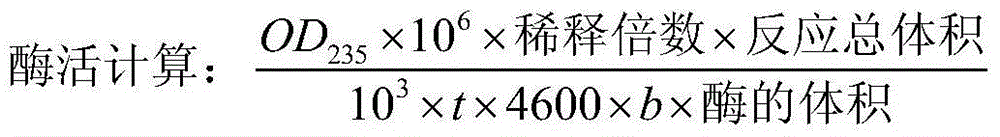

[0029] Embodiment one: the fermentation of pectinase

[0030] Prepare 50ml BMGY liquid medium (yeast extract 0.5g peptone 1.0g, yeast nitrogen source (YNB) 0.27g, ammonium sulfate 0.5g, pH6.0 phosphate buffer 5ml, glycerin 5ml, water 50ml) and 50mlBMMY liquid medium ( Yeast extract 0.5g, peptone 1.0g, yeast nitrogen source (YNB) 0.27g, ammonium sulfate 0.5g, pH 6.0 phosphate buffer 5ml, water 50ml), sterilized at 121°C, prepared 100ml solid YPD medium (glucose 2.0 g, peptone 2.0g, yeast extract 1.0g, agar 1.5g, distilled water 100ml), sterilized at 108°C and poured onto the plate. Streak the preserved GS115 / pel168s-9k strain on a solid YPD plate to activate it; select a single colony from the above YPD plate and inoculate it into a 250mL Erlenmeyer flask, which contains 50ml of liquid BMGY medium, and put it into a shaker bed, cultured at 28°C and 220rpm for 2 days, transferred the fermented bacterial solution into a sterilized sterile centrifuge tube on an aseptic operating ...

Embodiment 2

[0031] Embodiment two: the enzymolysis of 330U pectinase of 100ml substrate

[0032] Dissolve 2.0 g of the substrate in 100 ml of pH9.4 buffer, adjust the pH to about 9 with concentrated NaOH, preheat in a water bath at 50 ° C, add 3 ml of the enzyme solution prepared in Example 1 (ie: 330 U of pectin per 10 g of pectin Enzyme), react at 50°C, the reaction time is 2h, during the reaction process, use a glass rod to stir continuously, add 4.0g substrate every 5min in the next 10min and adjust the pH to about 9 with NaOH (5M). During the subsequent reaction process, the pH was also adjusted every 5 minutes, so that the pH was maintained at about 9 during the entire reaction process. Results After 2 hours of enzymolysis, the fluidity of the enzymolysis solution was good, and the hydrolysis rate of pectin was measured to be 93%.

Embodiment 3

[0033] Embodiment three: the enzymatic hydrolysis of 11U pectinase of 100ml substrate

[0034] Dissolve 2.0 g of the substrate in 100 ml of pectinase buffer at pH 9.4, adjust the pH to about 9 with NaOH (5M), preheat in a 50°C water bath, add 100 μl of the enzyme solution prepared in Example 1 (i.e., every 10 g Pectin 11U pectinase), react at 50°C, the reaction time is 2h, during the reaction, use a glass rod to stir continuously, add 4.0g of substrate every 5min in the next 10min and adjust the pH with NaOH (5M) To about 9, the pH should be adjusted every 5 minutes in the subsequent reaction process, so that the pH is maintained at about 9 during the entire reaction process. The result was that the pectin added after 2 hours was not completely dissolved, the enzymatic solution was viscous, and the substrate was not completely enzymatically hydrolyzed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com