Mechanical activating and strengthening cobalt white alloy cobalt leaching technology

A technology of mechanical activation and cobalt white alloy, which is applied in the field of metal smelting to achieve the effect of low cost and high leaching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

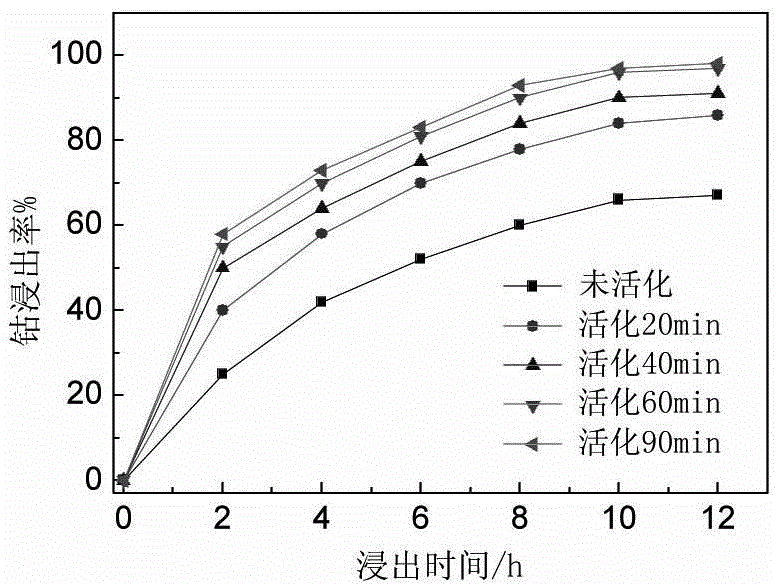

[0042]Experimental fixed conditions: leaching agent sulfuric acid concentration 3.0mol / L, liquid-solid ratio 8:1, stirring speed 150r / min, reaction temperature 80°C, air volume 4L / min, investigate the change trend of activation time and reaction time on cobalt leaching rate , the result is as figure 1 shown.

[0043] Depend on figure 1 It can be seen that the effect of activation time on the leaching rate of cobalt is very obvious. Compared with unactivated white metal, the leaching rate of cobalt and the final leaching rate of white metal are significantly improved after activation. And with the prolongation of the activation time, the leaching rate of cobalt increases correspondingly, but after the activation time exceeds 60min, the improvement of the final leaching rate of cobalt by prolonging the activation time is very limited. The cobalt leaching rate of the unactivated white alloy starts to increase slowly, and the final leaching rate is only 63.2%. At 40min, 60mi...

Embodiment 2

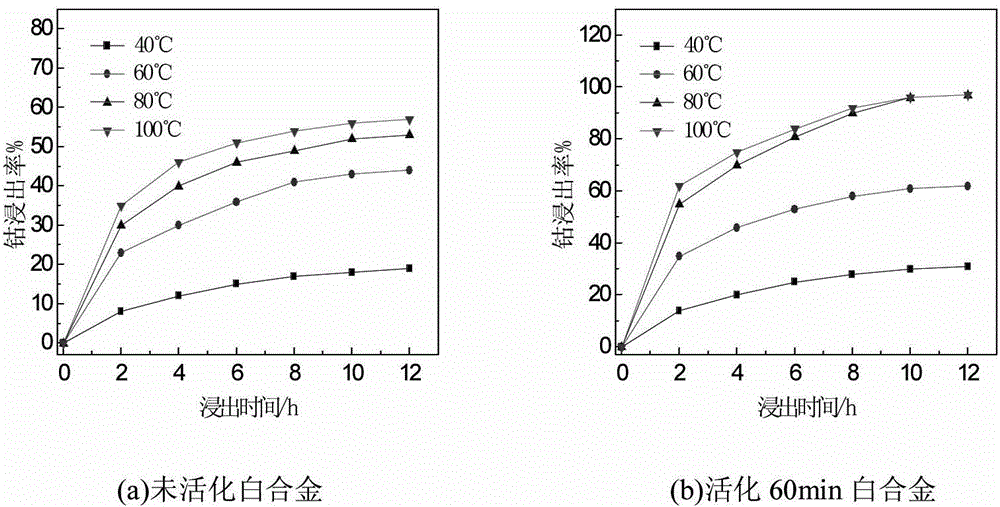

[0045] Experimental fixed conditions: Take two white metal ore samples, unactivated and activated for 60 minutes, the sulfuric acid concentration of the leaching agent is 3.0mol / L, the liquid-solid ratio is 8:1, the stirring speed is 150r / min, the air volume is 4L / min, and the leaching temperature and time are investigated. The change trend of cobalt leaching rate, the results are as follows figure 2 shown.

[0046] Depend on figure 2 It can be seen that the reaction temperature has a significant impact on the leaching rate of cobalt whether the white metal is activated or not. When the reaction temperature is 40°C, no matter whether it is activated or not, the cobalt leaching rate is very low after 12 h of reaction, and the cobalt leaching rate increases slightly after activation; when the reaction temperature is 60°C, the cobalt leaching rate of unactivated ore It was 45.3%, and it was 60.5% after activation for 60 minutes, an increase of 15.2%. When the reaction temper...

Embodiment 3

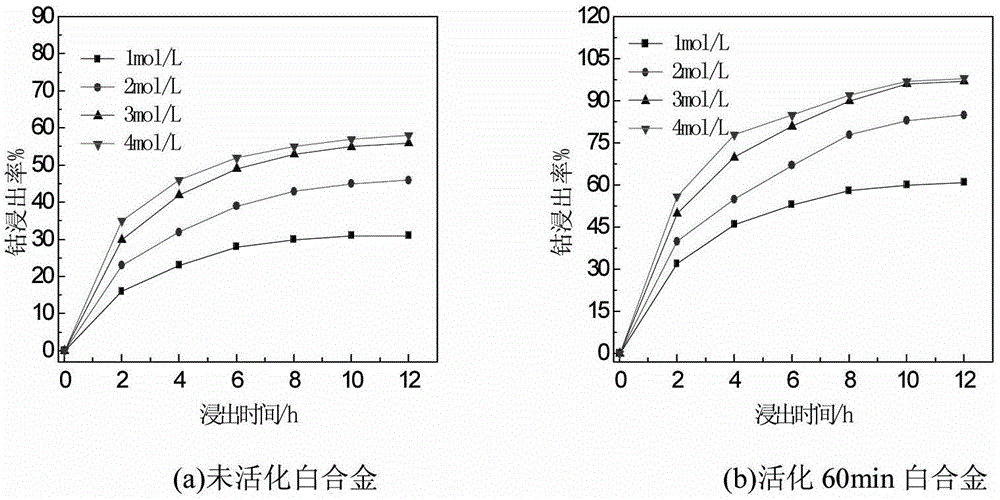

[0048] Experimental fixed conditions: two white metal ore samples, unactivated and activated for 60 minutes, were taken, the liquid-solid ratio was 8:1, the stirring speed was 150r / min, the reaction temperature was 80°C, and the air volume was 4L / min. rate change trend, the results are as follows image 3 shown.

[0049] It can be seen from the figure that with the increase of the sulfuric acid concentration of the leaching agent, the cobalt leaching rate of the activated and unactivated white alloy ore increases with the increase of the sulfuric acid concentration. For unactivated white alloy ore, when the concentration of the leaching agent is 1mol / L, the cobalt leaching rate increases continuously with the prolongation of the leaching time, and tends to be flat after 6 hours, because the concentration of sulfuric acid decreases at this time, and the reaction speed is very small. As the process progresses, the thickness of the product layer gradually increases, and the diff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com