Triazolone wettable powder capable of improving heat storage suspension rate and stability, and production method

A technology of wettable powder and suspension rate, which is applied in the field of pesticide preparation and its production, and can solve problems such as phytotoxicity, uneven application concentration in the field, and unqualified thermal storage stability of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

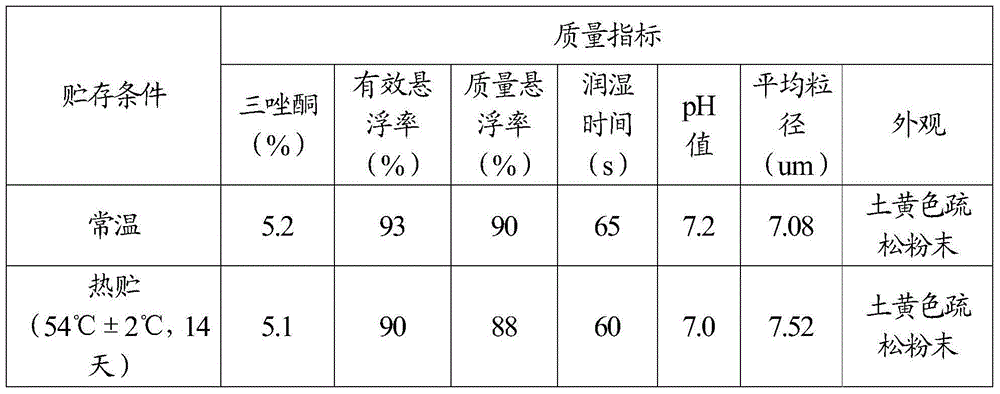

[0028] Embodiment 1 5% triadimefon wettable powder, production method and determination of various quality indexes

[0029] A triadimefon wettable powder prepared by the following production method:

[0030] (1) Emulsification and dispersion: Mix 5.2 g of triadimefon with 2 g of tristyrylphenol polyoxyethylene ether (Nongru No. 600), and carry out emulsification and dispersion for 5 minutes to form a binary mixture;

[0031] (2) Adsorption wrapping: add 4g of white carbon black to the above mixture, stir, absorb, and wrap for 5 minutes to form a ternary mixture;

[0032](3) Premixing-crushing-remixing: Add 2g sodium lignosulfonate, 0.5g sodium lauryl sulfate, and 86.3g diatomaceous earth into the above ternary mixture, pre-mix for 5-10min, and mix well , crushed by jet mill for 1-2 times, 95% of particle size passed through 1000 mesh sieve, and then mixed again for 5-10 minutes to obtain 5% triadimefon wettable powder.

[0033] The above-mentioned triadimefon wettable powder...

Embodiment 2

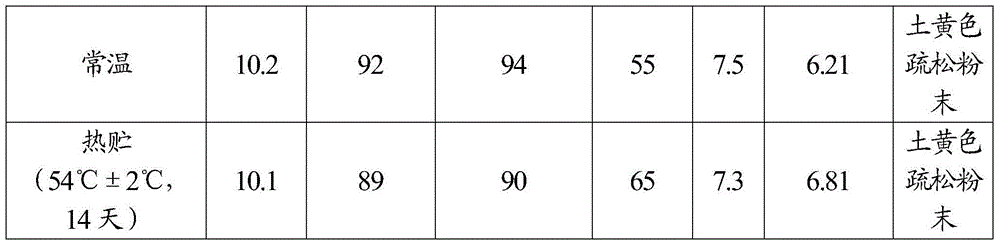

[0036] Embodiment two 10% triadimefon wettable powder, production method and determination of various quality indexes

[0037] A triadimefon wettable powder prepared by the following production method:

[0038] (1) Emulsification and dispersion: Mix 10.2 g of triadimefon with 3 g of fatty alcohol polyoxyethylene ether (Pingpinga O-35), and carry out emulsification and dispersion for 5 minutes to form a binary mixture;

[0039] (2) Adsorption wrapping: add 5g of white carbon black to the above mixture, stir, absorb, and wrap for 5 minutes to form a ternary mixture;

[0040] (3) Pre-mixing-crushing-remixing: Add 3g of diffusing agent NNO, 1g of pull-off powder BX, and 77.8g of bentonite into the ternary mixture, pre-mix for 5-10min, mix well, and pulverize by jet mill for 1 - Twice, after 95% of the particle size passes through a 1000-mesh sieve, followed by secondary mixing for 5-10 minutes to obtain 10% triadimefon wettable powder.

[0041] The above-mentioned triadimefon we...

Embodiment 3

[0045] Embodiment three 15% triadimefon wettable powder, production method and determination of various quality indicators (1)

[0046] A triadimefon wettable powder prepared by the following production method:

[0047] (1) Emulsification and dispersion: Mix 15.2g of triadimefon with 3g of polyarylphenol polyoxyethylene ether (YUS-FS1), and carry out emulsification and dispersion for 5 minutes to form a binary mixture;

[0048] (2) Adsorption wrapping: add 8g of white carbon black to the above mixture, stir, absorb, and wrap for 5 minutes to form a ternary mixture;

[0049] (3) Premixing—crushing—remixing: Add 5g of sodium lignosulfonate (Ufoxane3A), 1.5g of Morwet EFW, and 67.3g of light calcium carbonate into the ternary mixture, premix for 5-10min, and mix well. Pulverize 1-2 times with an airflow mill, 95% of the particle size passes through a 1000-mesh sieve, and then perform secondary mixing for 5-10 minutes to obtain 15% triadimefon wettable powder.

[0050] The above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com