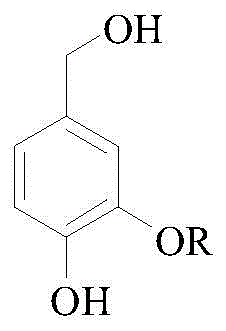

Preparation of nano-palladium catalyst as well as application of nano-palladium catalyst to synthesis of vanillin compounds

A catalyst and nano-palladium technology, applied in the preparation of organic compounds, carbon-based compounds, physical/chemical process catalysts, etc., can solve the problems of long process routes, low reaction efficiency, and many by-products, achieving good selectivity, Environmentally friendly, easy-to-separate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] One, the preparation of nano palladium catalyst

[0027] Under an argon atmosphere, add 1 g of nano-sized magnesium oxide support and 0.5 mmol of palladium salt into 50 ml of deionized water to form an impregnating solution, and then fully stir at 5°C for 12 hours to obtain a brown magnesium oxide-supported palladium salt catalyst. Filter and dry in vacuo; then weigh 1g of the above catalyst and add 1.5g of sodium borohydride to 30ml of dry ethanol solution in a hydrogen atmosphere, and stir thoroughly at 5°C for 5h to obtain a black zero-valent palladium catalyst supported on magnesium oxide , the solid was filtered and washed three times with deionized water and acetone, and dried in vacuum to obtain the final catalyst.

[0028] 2. Synthesis of vanillin compounds

[0029] Take the synthesis of vanillin as an example:

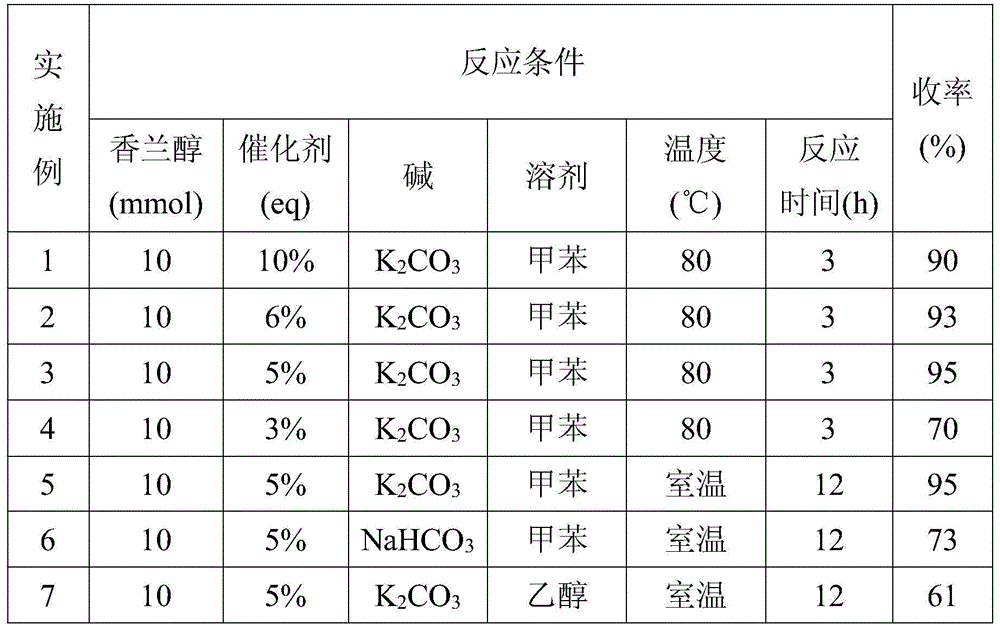

Embodiment 1

[0031] Add vanillin (1.54g, 10mmol), nano-palladium catalyst (0.7g, 10%), potassium carbonate (1.66g, 12mmol) and 30ml of toluene into a 50ml three-necked flask, and react at 80°C for 3h under magnetic stirring. After the reaction, cool the reaction solution, filter and recover the catalyst, add an equal volume of deionized water, separate the organic phase, extract the water phase with ethyl acetate three times, each time for 5min, combine the organic phase, spin dry under reduced pressure, and use column chromatography The desired product was isolated 1.4 g in 90% yield.

Embodiment 2

[0033] Add vanillin (1.54g, 10mmol), nano-palladium catalyst (0.4g, 6%), potassium carbonate (1.66g, 12mmol) and 30ml of toluene into a 50ml three-necked flask, and react at 80°C for 3h under magnetic stirring. After the reaction, cool the reaction solution, filter and recover the catalyst, add an equal volume of deionized water, separate the organic phase, extract the water phase with ethyl acetate three times, each time for 5min, combine the organic phase, spin dry under reduced pressure, and use column chromatography The desired product was isolated 1.43g in 93% yield.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com