Method for co-processing anaerobic digested sludge in cement kiln

A technology of digesting sludge and co-processing, applied in chemical instruments and methods, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., to save equipment, water consumption and energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

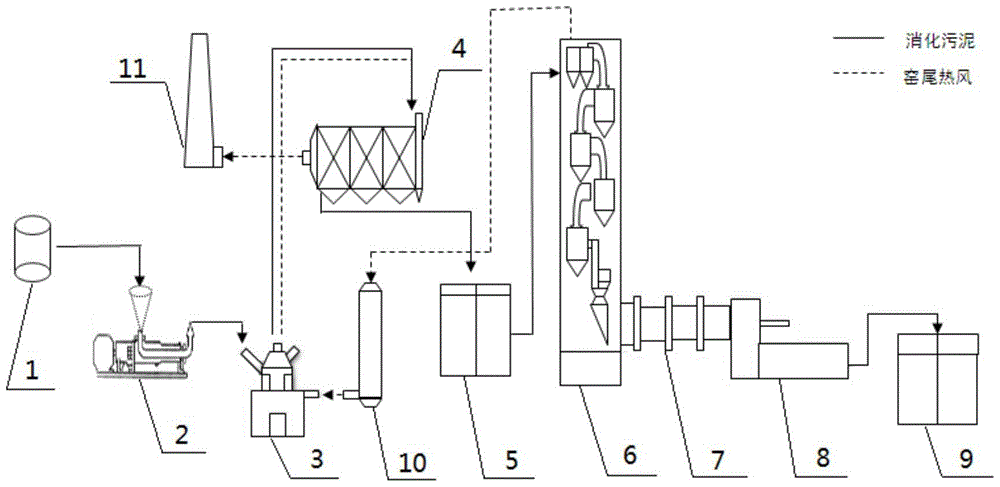

[0026] Co-processing of anaerobic digested sludge in cement kilns figure 1 Shown: First, the sludge is subjected to anaerobic digestion treatment, the water content of the digested sludge is 70%, and the digested sludge is sent from the digested sludge storage tank 1 to the raw material mill 3 through the screw pump 2, and cement raw materials such as limestone and shale It is also added to the raw material mill 3 and mixed with it. The added amount of digested sludge is 3%. In the raw material mill 3, each material is ground and dried, and after being collected by the bag filter 4, it enters the raw meal homogenization storehouse 5. After homogenization, it is sent to the pre-decomposition system 6 for preheating and decomposition, and then enters the rotary kiln 7 for incineration to prepare cement, and then enters the cooler 8 and clinker storage 9 in turn to obtain cement products. The raw material mill 3 is also connected to the humidification tower 10 , and the other end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com