Polymer grafting modified silicon dioxide nanosheet as well as preparation method and use thereof

A technology of silica and graft modification, which is applied in the field of rubber and plastic fillers, can solve the problems of not being able to significantly improve the interfacial behavior of polymers, uneven distribution, and difficulty in synergism, so as to improve the blending effect, improve the interfacial behavior, Significantly anisotropic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

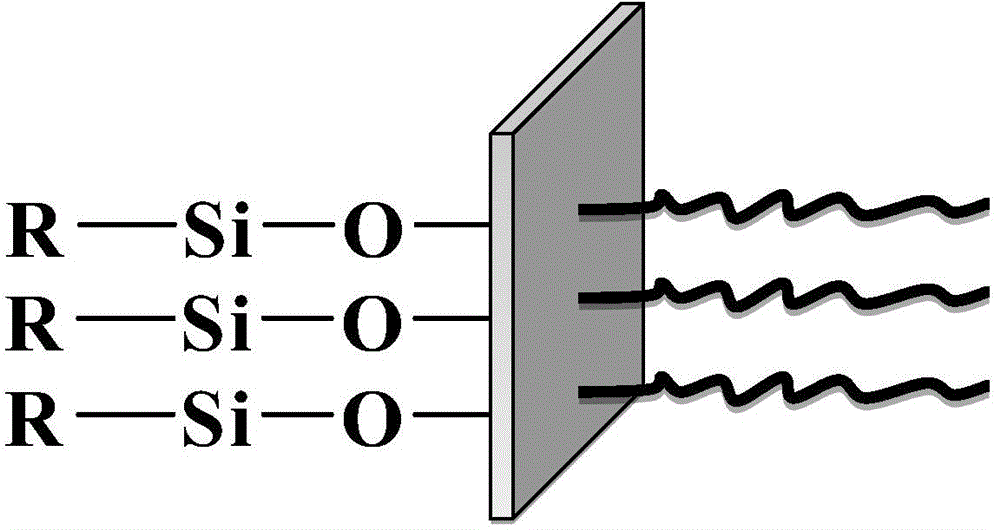

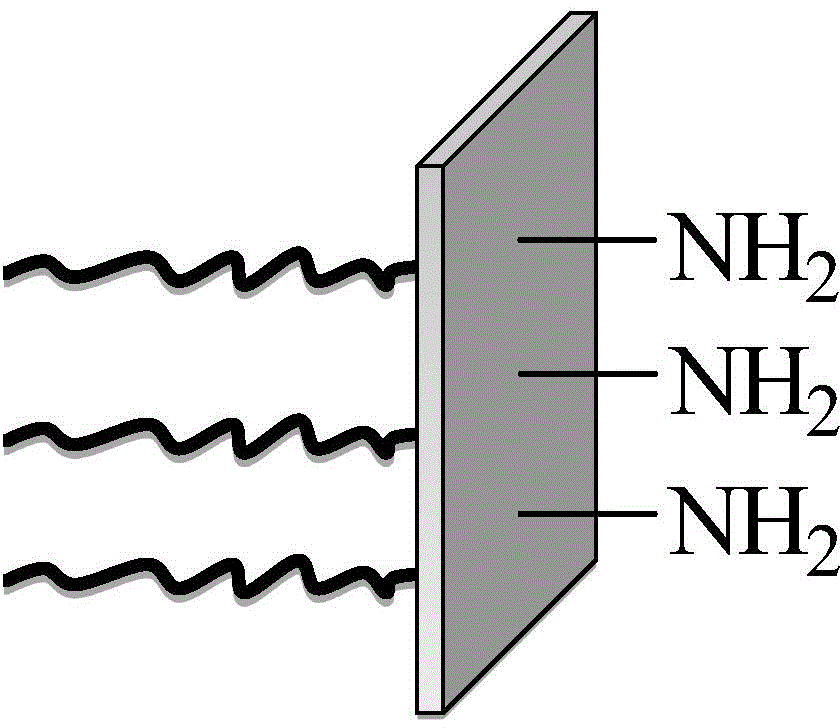

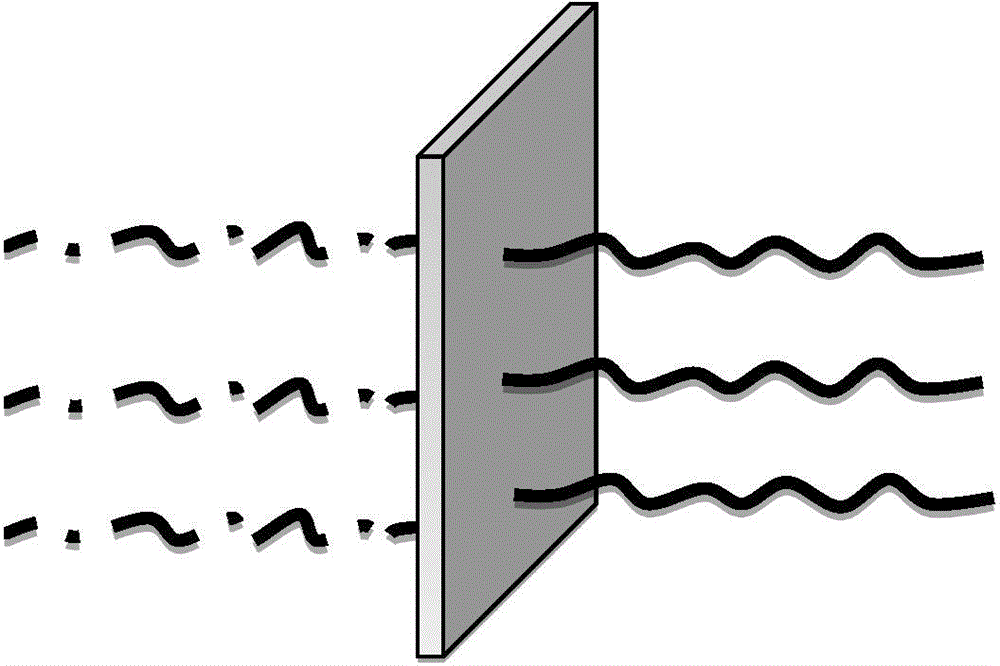

[0041] Add 0.2g of silica nanoflakes, 100mL of anhydrous toluene, and 1mL of methyltrimethoxysilane into a 250mL round-bottomed flask, react at 70°C for 18h, wash twice with toluene, and then wash twice with dry n-hexane to obtain Silanol-terminated silica nanoflakes. Add 0.2g of capped silica nanoflakes, 100mL of dichloromethane, 3mL of bromoacetyl bromide, and 4mL of triethylamine into a 250mL round-bottom flask, react at room temperature for 18h, and wash 5 times with dichloromethane to obtain silanol-capped bromine-grafted silica nanoflakes. Add 100mL cyclohexane, 50mL isoprene, 0.4mL 2.7mol / L n-butyllithium into a 250mL sealed and strictly dried round-bottomed flask, react at 25°C for 1 hour at a magnet speed of 500rpm, and use a vacuum pump to remove the residual monomers and solvents. Disperse 0.2g of dried silica nanoflakes into 100mL of cyclohexane, directly add to the above polymerization system, adjust the rotation speed to 700rpm, keep the temperature at 35°C, ad...

Embodiment 2

[0043] Add 0.2g of silica nanoflakes, 100mL of anhydrous toluene, and 1mL of methyltrimethoxysilane into a 250mL round-bottomed flask, react at 70°C for 18h, wash twice with toluene, and then wash twice with dry n-hexane to obtain Silanol-terminated silica nanoflakes. In a 250mL round-bottomed flask, add 0.2g of capped silica nanoflakes, 100mL of dichloromethane, 3mL of 3-isocyanate propene, and 4mL of triethylamine, react at room temperature for 18h, and wash 5 times with dichloromethane to obtain Silanol-terminated bromine-grafted silica nanoflakes. Add 100mL cyclohexane, 50mL butadiene, 0.4mL 2.7mol / L n-butyllithium into a 250mL sealed and strictly dried round-bottomed flask, and react for 1 hour at 25°C with a magneton rotation speed of 500rpm. bodies and solvents. Disperse 0.2g of dried silica nanoflakes into 100mL of cyclohexane, directly add to the above polymerization system, adjust the rotation speed to 700rpm, keep the temperature at 35°C, add 3mL of methanol after...

Embodiment 3

[0045] Add 0.2g of silica nanoflakes, 100mL of anhydrous toluene, and 1mL of methyltrimethoxysilane into a 250mL round-bottomed flask, react at 70°C for 18h, wash twice with toluene, and then wash twice with dry n-hexane to obtain Silanol-terminated silica nanoflakes. Add 0.2 g of capped silica nanoflakes, 100 mL of dichloromethane, 3 mL of bromoisobutyryl bromide, and 4 mL of triethylamine into a 250 mL round-bottomed flask, react at room temperature for 18 h, and wash 5 times with dichloromethane to obtain Si Hydroxy-terminated bromine-grafted silica nanoflakes. Add 100mL cyclohexane, 50mL styrene, 0.4mL 2.7mol / L n-butyllithium into a 250mL sealed and strictly dried round-bottomed flask, and react at 25°C for 1 hour at a magnet speed of 500rpm, and use a vacuum pump to remove residual monomers and solvents. Disperse 0.2g of dried silica nanoflakes into 100mL of cyclohexane, directly add to the above polymerization system, adjust the rotation speed to 700rpm, keep the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com