A kind of polyolefin alloy material and preparation method thereof

A technology of alloy materials and polyolefins, applied in the field of new polyolefin materials, can solve the problems of long polybutene crystal transformation time and narrow polymerization temperature window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

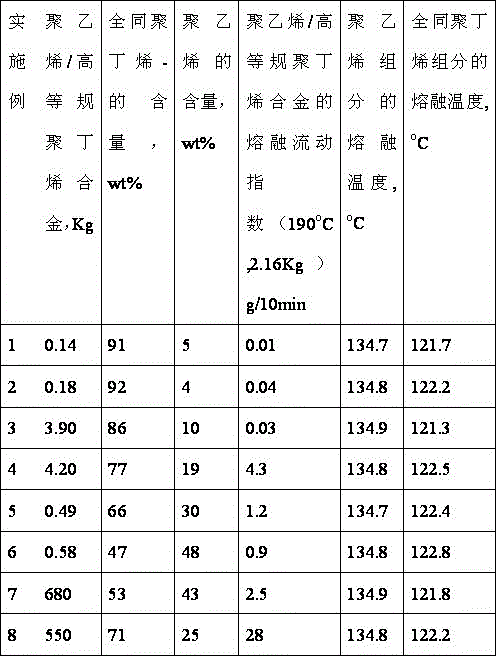

Examples

Embodiment 1

[0049] 1L full-sealed magnetic stirring stainless steel pressure polymerization kettle, pumped and replaced with high-purity nitrogen several times, then metered and added triethylaluminum (Al) and external electron donor diphenyldimethoxysilane (Si ) and MgCl 2 Loaded TiCl 4 Catalyst (Ti content 2.5 wt.%) 0.25g, add ethylene 0.05Kg, wherein Al / Ti=50 (molar ratio), Al / Si=10 (molar ratio). 60 oC Stir the polymerization for 5 minutes, then lower the temperature and evacuate ethylene under reduced pressure, add 0.2Kg of butene-1 to the reactor, react at 30°C for 6 hours, and obtain 140g of powdery polymer directly after the drying is terminated. The properties of the alloy are shown in Table 1.

Embodiment 2

[0051] 1L full-sealed magnetic stirring stainless steel pressure polymerization kettle, pumped and replaced with high-purity nitrogen several times, then metered 100ml of hexane, triethylaluminum (Al), and external electron donor cyclohexyltrimethoxysilane into the reaction kettle (Si) and MgI 2 Loaded TiCl 4 Catalyst (Ti content 2.5 wt.%) 0.25g, add ethylene 0.05Kg, wherein Al / Ti=80 (molar ratio), Al / Si=20 (molar ratio). 70 oC Stir and polymerize for 10 minutes, then lower the temperature and evacuate ethylene and hexane under reduced pressure, add 0.2Kg of butene-1 to the reactor, react at 35°C for 8 hours, and obtain 180g of powdery polymer directly after drying. The properties of the alloy are shown in Table 1.

Embodiment 3

[0053] 10L full-sealed magnetic stirring stainless steel pressure polymerization kettle, pumped and replaced several times with high-purity nitrogen, then metered and added 150ml of heptane, triethylaluminum (Al), and external electron donor diphenyl dimethoxide into the reaction kettle Silane (Si) and SiO 2 Load VlCl 3 Catalyst (V content 3.3 wt.%) 1.0g, add ethylene 0.5Kg, wherein Al / V=50 (molar ratio), Al / Si=20 (molar ratio). 60 oC Stir and polymerize for 20 minutes, then lower the temperature and empty the ethylene and solvent heptane, add butene-13.5Kg to the reactor, react at 40°C for 8 hours, and obtain 3.9Kg of powdered polymer directly after the drying is terminated. The properties of the polybutene alloy are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com