Metal-base copper clad laminate manufactured through high-performance RCC (resin coated copper foil) and applied to high-power LED

A high-power, high-performance technology, applied in the direction of metal layered products, non-polymer adhesive additives, epoxy resin glue, etc., can solve the gap in mechanical properties and electrical insulation performance, and has not entered the stage of substantive in-depth research and other problems, to achieve low expansion coefficient, high moisture resistance, good effect of integrated development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A metal-based copper-clad laminate for high-power LEDs made of high-performance RCC, including an epoxy resin composition, wherein the mass fraction of the solid component of the epoxy resin composition is: (A) bisphenol A type epoxy 5 parts of resin, 5 parts of dicyclopentadiene phenol epoxy resin; (B) 5 parts of rubber; (C) 50 parts of filler; (D) 1 part of dicyandiamide; (E) 0.1 part of 2-methylimidazole,

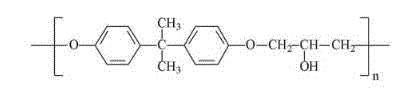

[0036] Wherein, the epoxy equivalent of bisphenol A type epoxy resin is 430, and the Mooney viscosity of nitrile rubber is 30, and wherein filler is the mixture of aluminum oxide, aluminum hydroxide and magnesium hydroxide, and wherein aluminum oxide accounts for the total weight of filler 60%, aluminum hydroxide accounts for 20% of filler gross weight, and magnesium hydroxide accounts for 20% of filler gross weight; Wherein said phenoxy resin structural formula is:

[0037]

[0038] The number average molecular weight is 10000;

[0039] Described dicyclopenta...

Embodiment 2

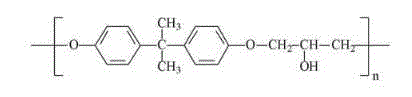

[0045] A metal-based copper-clad laminate for high-power LEDs made of high-performance RCC, including an epoxy resin composition, wherein the mass fraction of solid components of the epoxy resin composition is: (A) bisphenol A epoxy resin 25 parts, 5 parts of phenoxy resin, 20 parts of dicyclopentadiene phenol epoxy resin; (B) 25 parts of rubber; (C) 70 parts of filler; (D) 5 parts of m-phenylenediamine; Base-4-methylimidazole 1 part, wherein the amine curing agent is dicyandiamide, the accelerator is 2-methylimidazole, the epoxy equivalent of bisphenol A epoxy resin is 450, and the Mooney viscosity of nitrile rubber 40, wherein the filler is a mixture of alumina, aluminum hydroxide and magnesium hydroxide, wherein alumina accounts for 80% of the total weight of the filler, aluminum hydroxide accounts for 10% of the total weight of the filler, and magnesium hydroxide accounts for 10% of the total weight of the filler %; wherein the phenoxy resin structural formula is:

[0046...

Embodiment 3

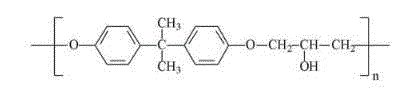

[0053] A metal-based copper-clad laminate for high-power LEDs made of high-performance RCC, including an epoxy resin composition, wherein the mass fraction of solid components of the epoxy resin composition is: (A) bisphenol A epoxy resin 35 parts, 10 parts of phenoxy resin, 30 parts of dicyclopentadiene phenol epoxy resin; (B) 35 parts of rubber; (C) 80 parts of filler; (D) 10 parts of dicyandiamide and diaminodiphenylmethane mixture; (E) 2 parts of a mixture of 2-ethyl-4-methylimidazole and 2-phenylimidazole, wherein the epoxy equivalent of bisphenol A epoxy resin is 450, and the Mooney viscosity of nitrile rubber is 40, wherein The filler is a mixture of alumina, aluminum hydroxide and magnesium hydroxide, wherein alumina accounts for 80% of the total weight of the filler, aluminum hydroxide accounts for 10% of the total weight of the filler, and magnesium hydroxide accounts for 10% of the total weight of the filler; Described phenoxy resin structural formula is:

[0054] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com