Composition for reinforcing binding power and use thereof

A technology of composition and cohesion, applied in the direction of non-macromolecular adhesive additives, non-macromolecular organic compound adhesives, adhesives, etc., can solve the problem of high-grade energy-saving wooden doors and windows that cannot meet the high toxicity of vinyl acetate , poor environmental protection performance and other problems, to achieve excellent curing time, excellent bonding strength, and improve the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

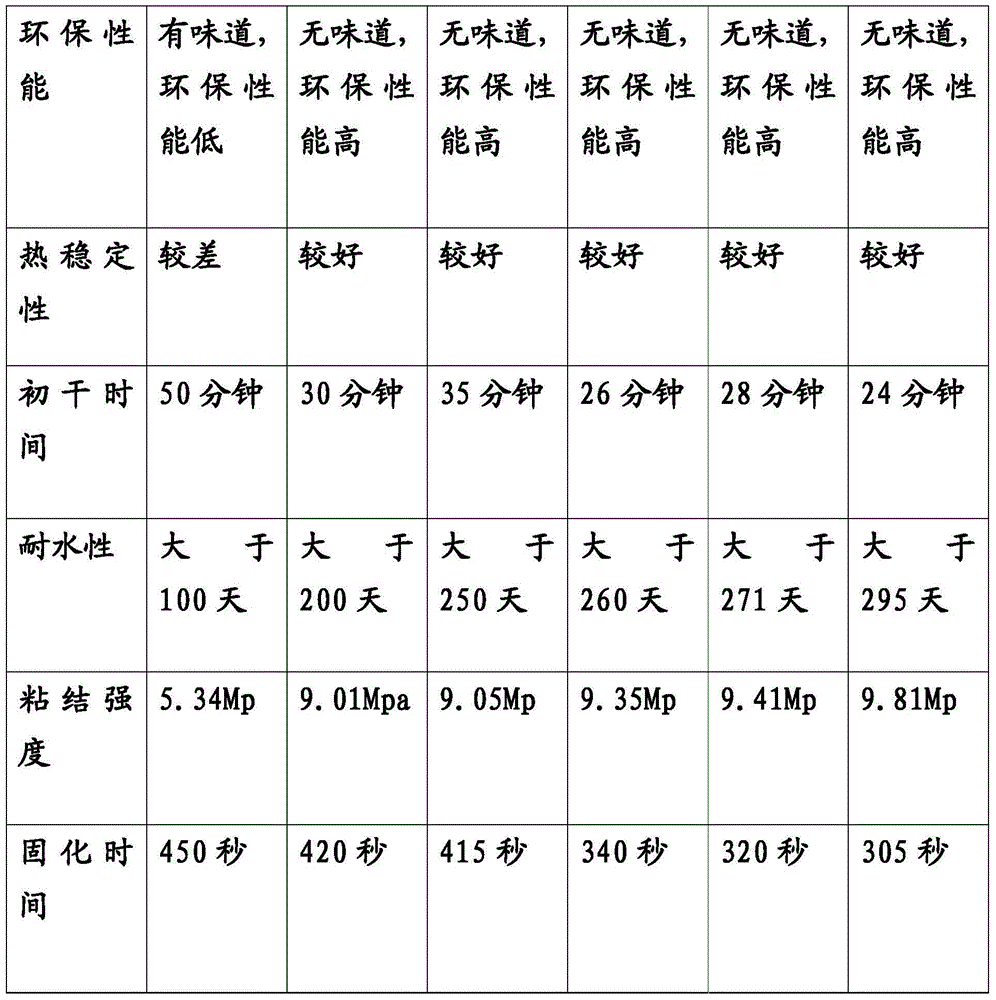

Embodiment 1

[0018] This embodiment relates to a composition for enhancing adhesion, and the composition can be used to prepare glue for connecting wooden parts, and the glue includes the following components in parts by weight:

[0019] Polyvinyl acetate 700,

[0020] Vinyl acetate 300,

[0021] polyvinyl alcohol 120,

[0022] Dibutyl phthalate 60,

[0023] Diethylene glycol dibenzoate 20,

[0024] Octanol 10,

[0025] Isopropanol 30,

[0026] Allyl methacrylate 10,

[0027] Ethylene glycol dimethacrylate 5,

[0028] Toluene diisocyanate 3,

[0029] Sodium bicarbonate 35,

[0030] water 1400,

[0031] Emulsifier 40, the emulsifier is sodium oleate (i.e. sodium octadecenoate);

[0032] Initiator 5, the initiator is ammonium persulfate.

[0033] All components involved in this example can be obtained through public commercial channels. In the present embodiment, the preparation method steps of the glue used for connecting wooden parts in the wooden window are as follows:

[003...

Embodiment 2

[0040] This embodiment relates to a composition for enhancing adhesion, and the composition can be used to prepare glue for connecting wooden parts, and the glue includes the following components in parts by weight:

[0041] Polyvinyl acetate 1050,

[0042] Vinyl acetate 350,

[0043] polyvinyl alcohol 145,

[0044] Dibutyl phthalate 100,

[0045] Diethylene glycol dibenzoate 40,

[0046] Octanol 15,

[0047] Isopropanol 45,

[0048] Allyl methacrylate 25,

[0049] Ethylene glycol dimethacrylate 10,

[0050] Toluene diisocyanate 7,

[0051] Sodium bicarbonate 50,

[0052] water 1500,

[0053] Emulsifier 50, the emulsifier is sodium dodecylbenzenesulfonate;

[0054] Initiator 10, the initiator is ammonium persulfate.

Embodiment 3

[0056] This embodiment relates to a composition for enhancing adhesion, and the composition can be used to prepare glue for connecting wooden parts, and the glue includes the following components in parts by weight:

[0057] Polyvinyl acetate 800,

[0058] Vinyl acetate 315,

[0059] Polyvinyl alcohol 125,

[0060] Dibutyl phthalate 80,

[0061] Diethylene glycol dibenzoate 25,

[0062] Octanol 12,

[0063] Isopropanol 35,

[0064] Allyl methacrylate 15,

[0065] Ethylene glycol dimethacrylate 7,

[0066] Toluene diisocyanate 4,

[0067] Sodium bicarbonate 39,

[0068] water 1450,

[0069] Emulsifier 45, the emulsifier is sodium dodecylbenzenesulfonate;

[0070] Initiator 6, the initiator is potassium persulfate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com