Preparation process of nutritional rice oil rich in oryzanol and vitamin E

A preparation process, rice oil technology, applied in the direction of fat oil/fat refining, fat production, edible oil/fat, etc., can solve the problem of loss of nutritional components, etc., achieve the effect of low operating temperature, low distillation pressure and high degree of separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

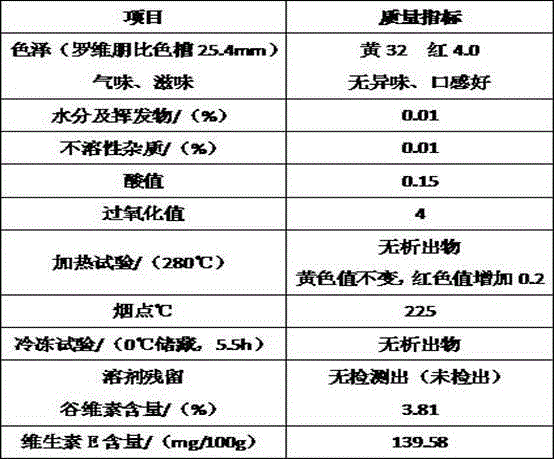

Embodiment 1

[0026] The crude oil from which impurities have been filtered out is heated up to 60°C by a spiral plate heater, and then a compound degumming agent is added. The compound degumming agent is a mixture of 0.2% of crude oil weight with 10% oxalic acid solution and 0.6% of crude oil weight with 6% NaCl solution, and the compound degumming agent is heated to 75°C in advance. The oil is mixed with the compound degumming agent for 35 minutes, and then enters the centrifuge to remove the colloid. After degumming, the oil enters the crystallization tank to cool to 10°C, the cooling rate is controlled at 2°C / h, the stirring speed is controlled at 10r / min, and the stirring is turned off after the oil temperature drops. After 72 hours of crystal growth, the oil enters the filter press to filter out wax. The dewaxed oil is firstly heated to 80°C by a heat exchanger and then enters the thin film evaporator. The vacuum degree of the thin film evaporator is 0.095MPa. After evaporating water ...

Embodiment 2

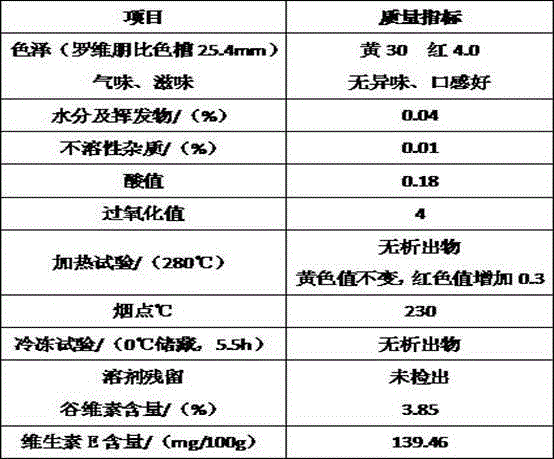

[0030]The crude oil from which impurities have been filtered out is heated to 65°C by a spiral plate heater, and then a compound degumming agent is added. The compound degumming agent is a mixture of oxalic acid solution with a volume concentration of 0.5% of the crude rice oil weight of 14%, and a NaCl solution of 0.8% of the crude rice oil weight and a volume concentration of 8%, and the compound degumming agent is heated to 80°C in advance. The oil is mixed with the compound degumming agent for 30 minutes, and then enters the centrifuge to remove the colloid. After degumming, the oil enters the crystallization tank to cool to 15°C, the cooling rate is controlled at 2°C / h, the stirring speed is controlled at 10r / min, and the stirring is turned off after the oil temperature drops. After 72 hours of crystal growth, the oil enters the filter press to filter out wax. The dewaxed oil is first heated to 80°C by a heat exchanger and then enters the thin film evaporator. The vacuum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com