Manufacturing method and product of high-conductivity and low-reflectivity metal mesh

A metal grid, low reflectivity technology, applied in electrical digital data processing, data processing input/output process, instruments, etc. Long exposure time and other problems, to achieve the effect of reducing reflectivity, easy operation, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0028] A method for manufacturing a metal grid with high conductivity and low reflectivity, comprising the following steps:

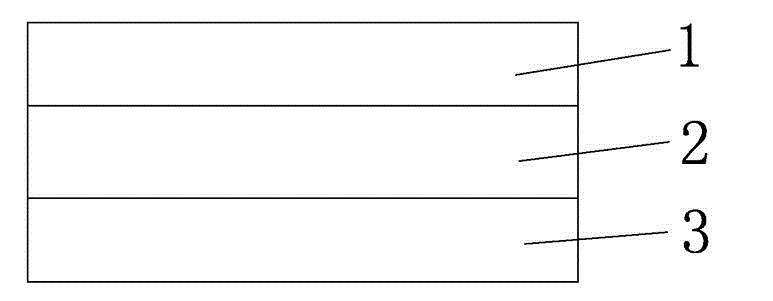

[0029] (1) Coating photoresist layers (1, 2) on the transparent substrate 3, the thickness of the photoresist layer is 20-60 microns, and the photoresist layer is formed by stacking two layers of photoresist layers with different etching rates (such as Figure 1~3 shown); and, the plasma etching rate of the photoresist material selected for the upper photoresist layer 1 is greater than the plasma etching rate of the photoresist material selected for the lower photoresist layer 2;

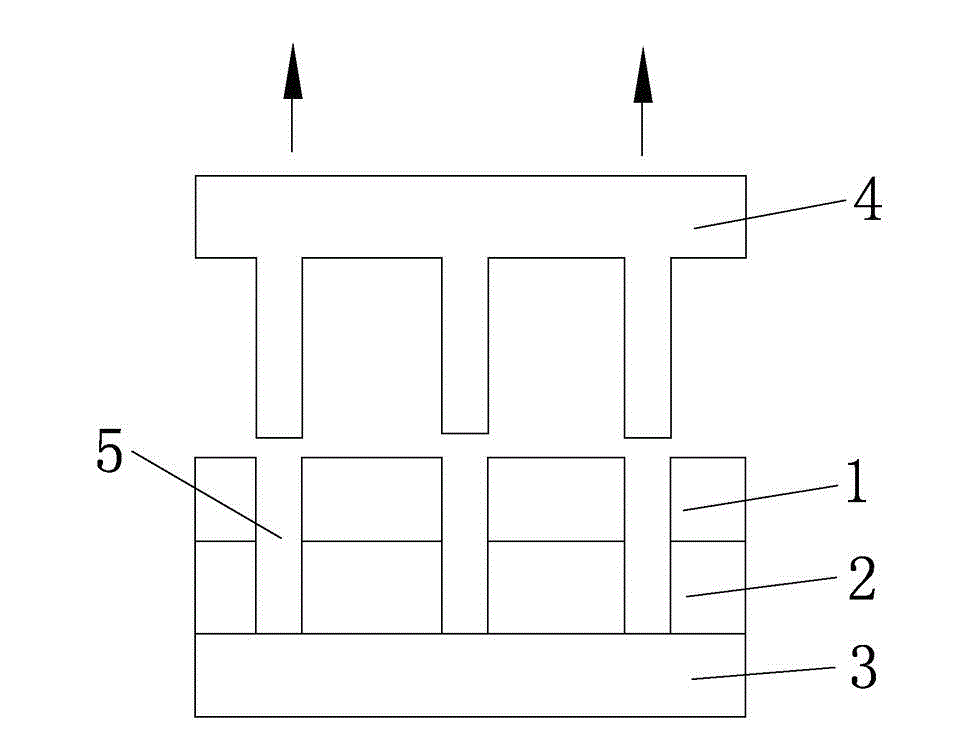

[0030] (2) The photoresist layer (1, 2) is imprinted by using the embossing template 4 with a raised circuit pattern on the bottom, and after the embossing template 4 is pulled out, a circuit pattern is formed in the photoresist layer (1, 2) Groove 5 (eg figure 2 shown);

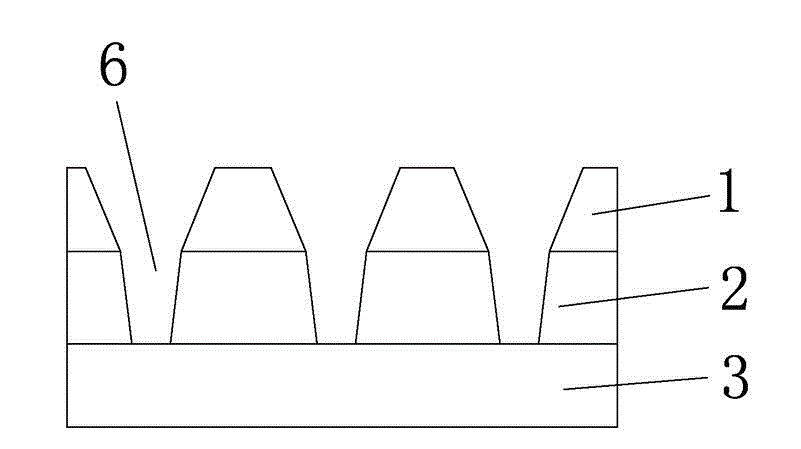

[0031] (3) Carry out plasma etching to the photoresist layer (1, 2) after embossing, expose transpare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com