Diamond schottky diode and manufacturing method thereof

A technology of Schottky diode and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem that the current density cannot meet the Achilles heel of power devices, and achieves the goal of reducing leakage current and improving reverse performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

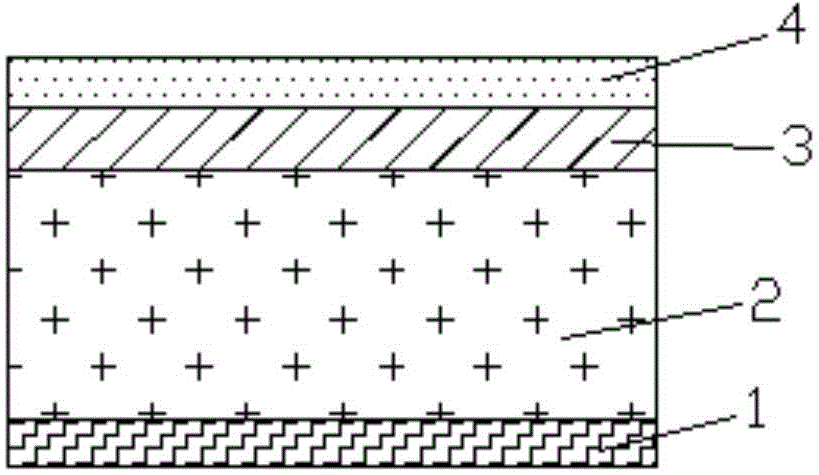

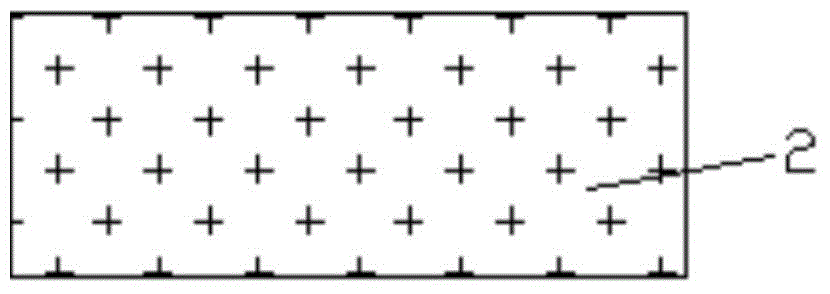

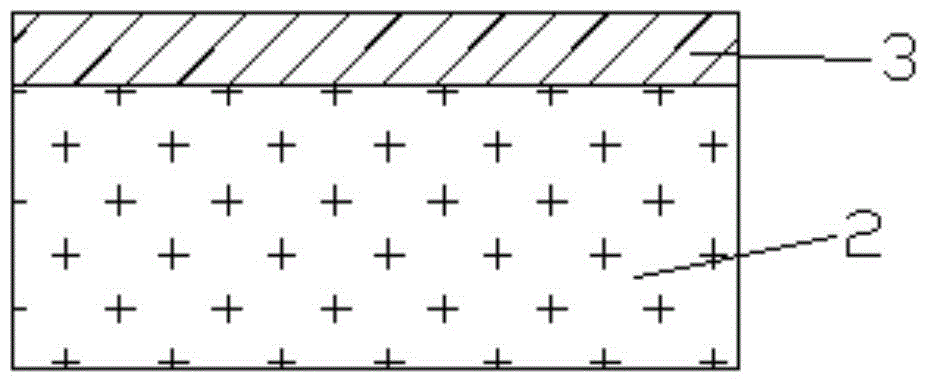

[0020] The main structure of the diamond Schottky diode is a metal electrode and a P-type (boron-doped) diamond film to form a diode. One of its important applications is high-voltage, high-current, and high-temperature high-power power conversion. At present, the P-type doping of diamond is relatively mature. The diamond Schottky diode made of P-type doped diamond has the advantages of low turn-on voltage, good high temperature resistance, large rectification ratio and fast switching speed. Since the breakdown electric field of diamond is much larger than that of other semiconductors, under the same withstand voltage requirements, diamond Schottky diodes can be made thinner and have smaller on-resistance. And because of its high thermal conductivity, it can effectively dissipate heat and have better stability.

[0021] In order to optimize the performance of diamond Schottky diodes, scientists have been trying to use different metals as the Schottky electrodes of diamond Scho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com