Graphene/ boron nitride/zinc oxide ultraviolet detector and preparation method thereof

An ultraviolet detector, zinc oxide technology, applied in the field of photoelectric detection, can solve the problem of large leakage current of devices, and achieve the effects of reducing leakage current, high ultraviolet responsivity, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

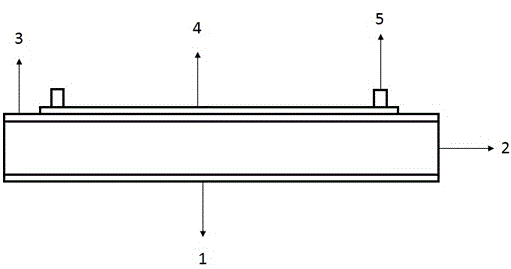

[0024] 1) Deposit gold electrodes on one side of a clean p-type doped ZnO bulk single crystal by electron beam evaporation;

[0025] 2) The obtained samples were sequentially immersed in deionized water, acetone and isopropanol for surface cleaning to remove the contamination on the ZnO surface during electrode preparation;

[0026] 3) Transfer 7 layers of boron nitride to the other side of the cleaned zinc oxide single wafer;

[0027] 4) transfer the single-layer graphene onto the above-mentioned boron nitride layer;

[0028] 5) Deposit silver electrodes on graphene by thermal evaporation process to obtain graphene / boron nitride / zinc oxide ultraviolet detectors.

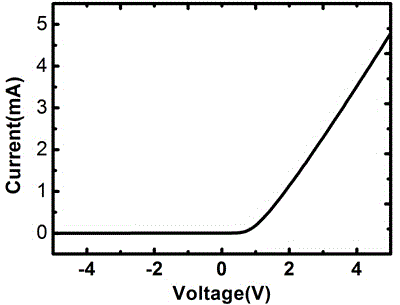

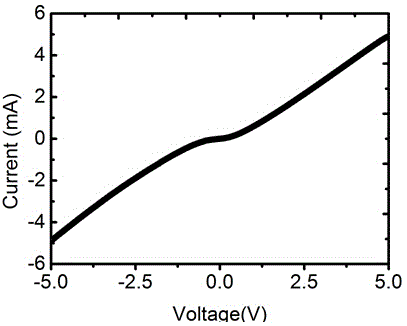

[0029] The IV curves of the ultraviolet detector made in this example under dark state and ultraviolet light are as follows figure 2 , image 3 As shown, it can be seen that the reverse bias current is small under the condition of no ultraviolet light, but under the condition of ultraviolet light, the reverse bi...

Embodiment 2

[0031] 1) Deposit a palladium electrode on one side of a clean n-type doped ZnO bulk single wafer by electron beam evaporation;

[0032] 2) The obtained samples were sequentially immersed in deionized water, acetone and isopropanol for surface cleaning to remove contamination on the ZnO surface during electrode preparation;

[0033] 3) Transfer 14 layers of boron nitride to the other side of the cleaned zinc oxide single wafer;

[0034] 4) Transferring two layers of graphene onto the above-mentioned boron nitride layer;

[0035] 5) Deposit gold electrodes on graphene by thermal evaporation process to obtain graphene / boron nitride / zinc oxide ultraviolet detectors.

Embodiment 3

[0037] 1) Electron beam evaporation is used to deposit nickel electrodes on the unpolished side of a clean single-sided polished n-type doped ZnO bulk single crystal;

[0038] 2) The obtained samples were sequentially immersed in deionized water, acetone and isopropanol for surface cleaning to remove contamination on the ZnO surface during electrode preparation;

[0039] 3) Transfer 20 layers of boron nitride to the polished surface of the above-mentioned cleaned zinc oxide single wafer;

[0040] 4) Transfer 1 layer of graphene onto the above-mentioned boron nitride;

[0041] 5) Deposit silver electrodes on graphene by thermal evaporation process to obtain graphene / boron nitride / zinc oxide ultraviolet detectors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com