Two novel crystal forms of 9-nitrocamptothecin and preparation methods thereof

A technology of nitrocamptothecin and crystal form, which is applied in the field of 9-nitrocamptothecin, can solve the problem that the solubility of 9-nitrocamptothecin crystal form is not significantly improved, it is difficult to ensure that the residual amount of organic solvent is qualified, and the preparation process cumbersome and other problems, to achieve the effect of easy industrial production, simple operation and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

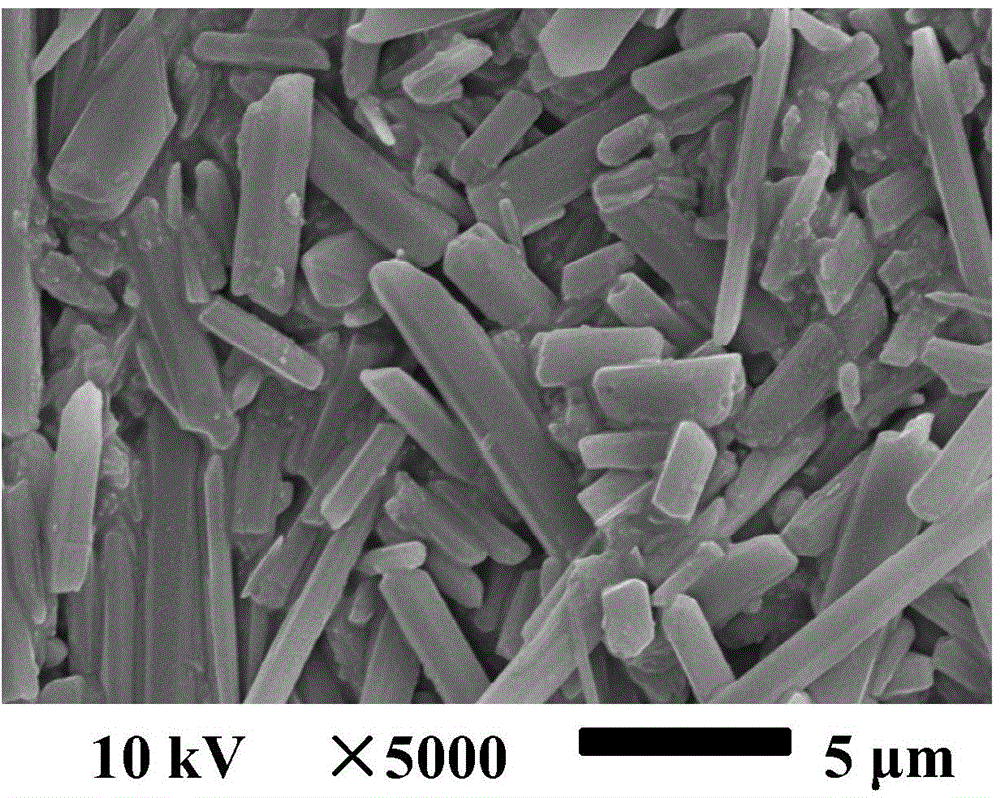

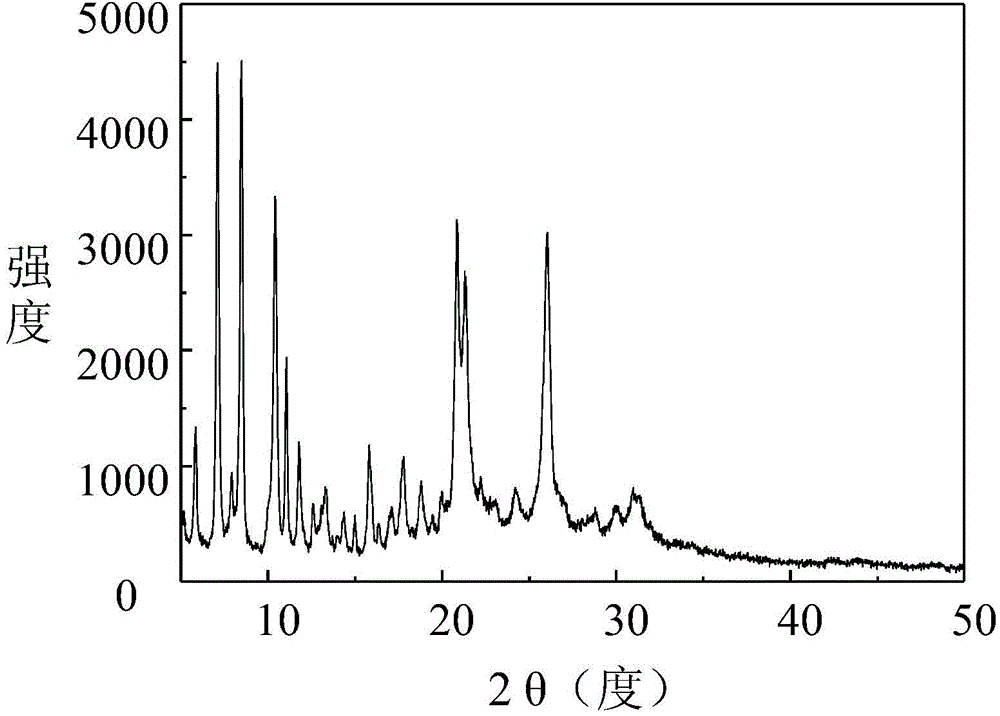

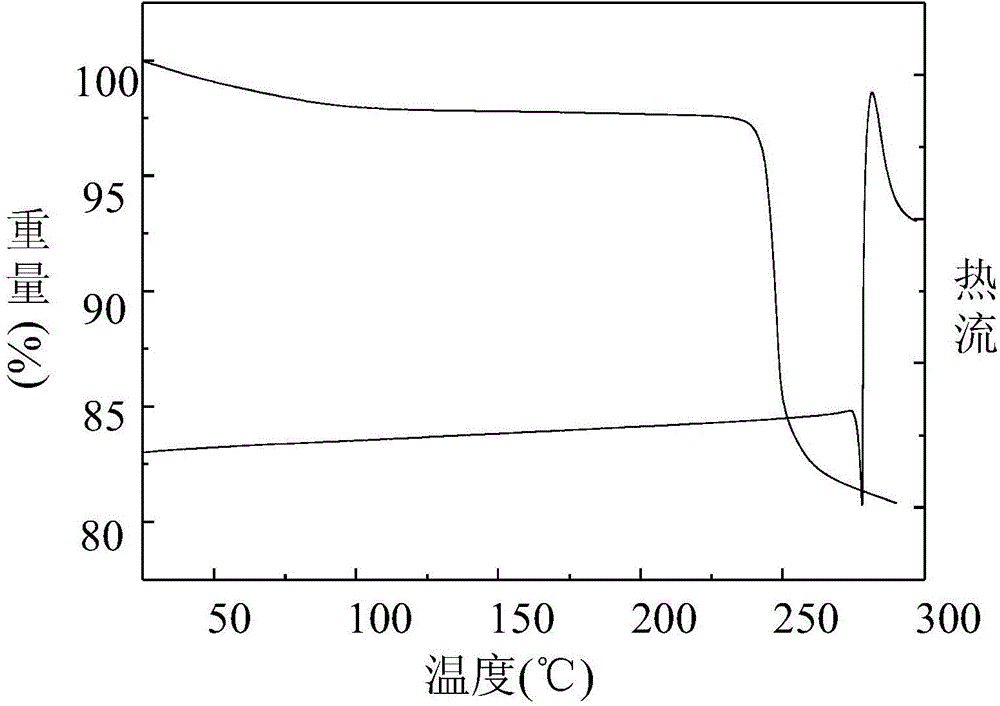

Embodiment 1

[0038] Preparation of 9-nitrocamptothecin crystal form I: Accurately measure 20ml DCM and 80ml EtOH to prepare a mixed solvent, accurately weigh 110mg 9-nitrocamptothecin, and dissolve it in the above mixed solvent to form a solution. In the control software, set the temperature of the settling tank to 45° C., the pressure to 125 bar, and the flow rate of carbon dioxide injected into the settling tank to be 20 g / min. Open the steel cylinder, pass carbon dioxide into the settling kettle with a high-pressure pump, and when the temperature and pressure in the still reach the set value, use another high-pressure pump to pass the mixed solvent into the settling kettle at a rate of 1.2ml / min. After 15 minutes, stop the flow. Into the mixed solvent, inject the 9-nitrocamptothecin solution at the same rate. After the sample injection is completed, continue to feed carbon dioxide for 40 minutes, stop the carbon dioxide pump, lower the pressure of the settling tank to atmospheric pressu...

Embodiment 2

[0042] Preparation of 9-nitrocamptothecin crystal form I: Accurately measure 20ml DCM and 80ml EtOH to prepare a mixed solvent, accurately weigh 90mg 9-nitrocamptothecin, and dissolve it in the above mixed solvent to form a solution. In the control software, set the temperature of the settling tank to be 40° C., the pressure to be 110 bar, and the flow rate of carbon dioxide injected into the settling tank to be 20 g / min. Open the steel cylinder, pass carbon dioxide into the settling kettle with a high-pressure pump, and when the temperature and pressure in the still reach the set value, use another high-pressure pump to pass the mixed solvent into the settling kettle at a rate of 0.9ml / min. After 15 minutes, stop the flow. Into the mixed solvent, inject the 9-nitrocamptothecin solution at the same rate. After the sample injection is completed, continue to feed carbon dioxide for 40 minutes, stop the control system, and take it out when the pressure of the settling tank is red...

Embodiment 3

[0045] Preparation of 9-nitrocamptothecin crystal form I: Accurately measure 20ml DCM and 80ml EtOH to prepare a mixed solvent, accurately weigh 50mg 9-nitrocamptothecin, and dissolve it in the above mixed solvent to form a solution. In the control software, set the temperature of the settling tank to be 40° C., the pressure to be 125 bar, and the flow rate of carbon dioxide injected into the settling tank to be 20 g / min. Open the steel cylinder, pass carbon dioxide into the settling kettle with a high-pressure pump, and when the temperature and pressure in the still reach the set value, use another high-pressure pump to pass the mixed solvent into the settling kettle at a rate of 0.6ml / min. After 15 minutes, stop the flow. Into the mixed solvent, inject the 9-nitrocamptothecin solution at the same rate. After the sample injection is completed, continue to feed carbon dioxide for 40 minutes, stop the control system, and take it out when the pressure of the settling tank is red...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Solubility | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com