Preparation method of hydrophobically modified cationic polyacrylamide

A polyacrylamide, hydrophobic modification technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve problems such as environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

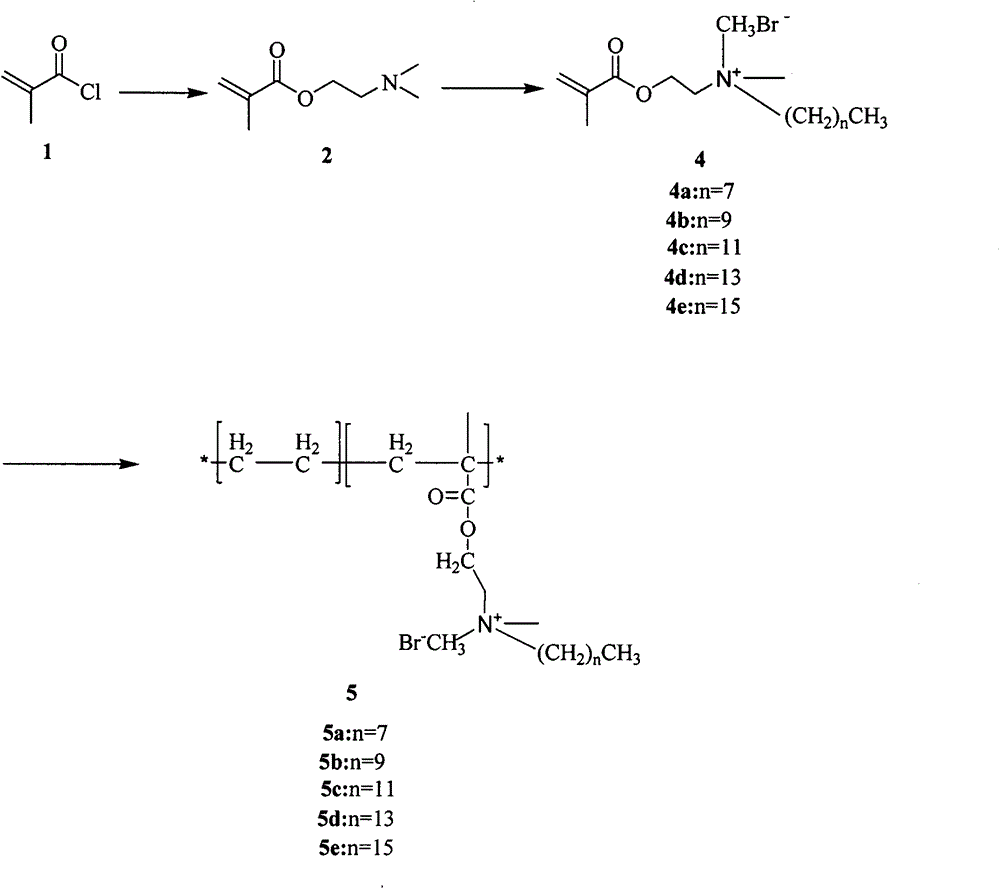

[0013] Embodiment 1. the synthesis of dimethylaminoethyl methacrylate (2)

[0014] Add 40mL dimethylaminoethanol and 100mL ether into a 250mL round bottom bottle, cool in an ice bath, slowly add 40g of methacryloyl chloride (1) dropwise under electromagnetic stirring, and finish the reaction after 4 hours. After filtration, the filtrate was concentrated and then distilled under reduced pressure, and the fraction at 55-57°C / 533.3Pa was collected to obtain the product dimethylaminoethyl methacrylate. yield: 90%, 1 H-NMR (500MHz, DMSO) δ: 6.025(s, 1H), 5.659-5.670(s, 1H), 4.159-4.198(t, 2H), 2.503-2.542(t, 2H), 2.185(s, 6H) , 1.887 (s, 3H).

Embodiment 2

[0015] Embodiment 2. The synthesis of methacryloyloxyethyl octyl ammonium bromide (4a)

[0016] In a one-necked flask, add the substance 2 purified by distillation, and bromooctane (3a) in an amount 1.1 times that of the substance 2. Acetone is used as a solvent, and the amount added is twice the sum of the volumes of substance 2 and alkyl bromide. The addition amount of p-methoxyphenol is 2mmol / L. The system was carried out at 35°C for 20 hours to terminate the reaction, and most of the acetone was removed by rotary evaporation, and an appropriate amount of anhydrous ether was added to precipitate, and the product was obtained by suction filtration. The product was recrystallized three times with anhydrous ethyl acetate, and dried in a vacuum oven to obtain the substance methacryloyloxyethyloctylammonium bromide (4a), yield: 83.1%, bp.=89°C-91°C , 1 H-NMR (500MHz, DMSO) δ: 6.087(s, 1H), 5.762-5.767(s, 1H), 4.535-4.544(t, 2H), 3.734-3.764(t, 2H), 3.328-3.359(t, 2H), 3.149 ...

Embodiment 3

[0017] Embodiment 3. the synthesis of methacryloyloxy ethyl decyl ammonium bromide (4b)

[0018] Dimethylaminoethyl methacrylate (2) and 1-bromodecane (3b) were prepared according to Example 2 to prepare methacryloxyethyldecylammonium bromide (4b), yield: 81.2%, bp.=90 ℃-92℃, 1 H-NMR (500MHz, DMSO) δ: 6.087(s, 1H), 5.762-5.767(s, 1H), 4.533-4.554(t, 2H), 3.744-3.774(t, 2H), 3.328-3.438(t, 2H), 3.146(s, 3H), 1.912(s, 3H), 1.259-1.682(m, 16H), 0.841-0.884(t, 3H).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com