Zero-emission metal and nonmetal surface cleaning agent with effects of oil removal, rust removal, scale removal, phosphorization, passivation, oxidation resistance and corrosion prevention

A non-metallic surface, zero-emission technology, applied in the direction of ampholyte/electroneutral surface active compounds, detergent compositions, detergent compounding agents, etc., can solve the problems of hidden pollution, heavy pollution, waste, etc., and save resources , environmental protection, no three wastes effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The multifunctional cleaning agent with recycling and zero discharge of the present invention will be described in more detail below in conjunction with the examples.

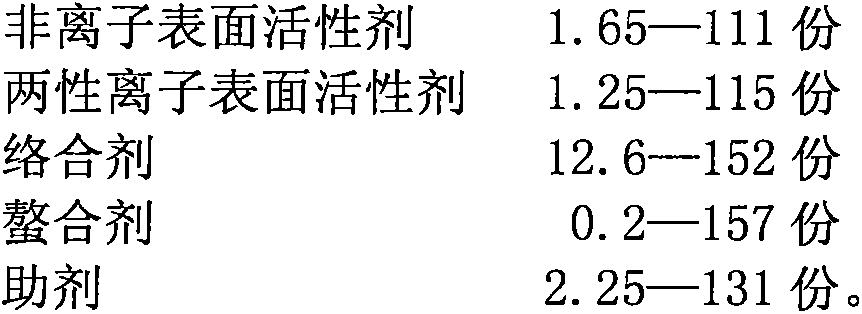

[0028] 1. Example 1—a descaling and cleaning agent with recycling, zero discharge, and wide applicability of various metals and nonmetals, its active components and parts by mass are:

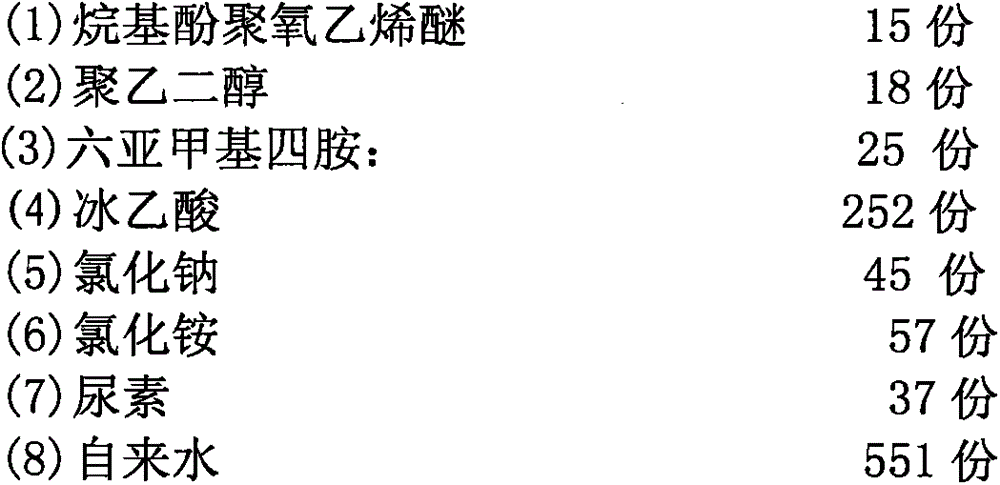

[0029]

[0030] Production operation rules: (1), (2), (3), and (5) are dissolved in tap water at 40-50°C respectively, added in turn and stirred evenly to cool to room temperature, and then added in turn (4), (6) , Item (7) is dissolved and stirred evenly to produce a concentrated transparent water-based process material, which is put into barrels after standing, labeled with a trademark, and leaves the factory. (Production, transportation, storage, storage, and use should all be ≥5°C)

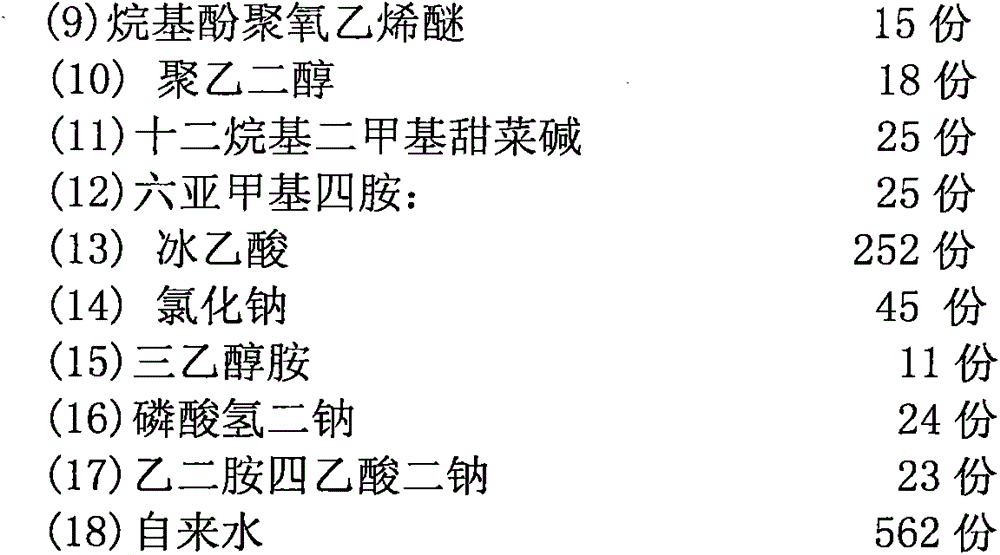

[0031] 2. Example 2——a descaling and cleaning agent with recycling, zero discharge, and synchronous multifunctional composite proper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com