Method for preparing novel carbon fiber toughened Ti (C,N) based metal ceramic material

A carbon fiber and metal-based technology, applied in the field of new high-performance Ti-based cermet materials and their preparation, can solve the problems of easy damage and fracture of finished carbon fibers, performance constraints of composite materials, and difficult processing, and achieve good surface integrity and excellent The effect of improving wear resistance, strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031]The preparation method comprises the following process steps and contents:

[0032] (1) Weighing: Weigh raw materials according to the composition designed for the novel Ti(C,N)-based cermet, and add 0-15% (mass fraction) of organic dispersant and binder.

[0033] (2) Mixing: Add the Ti(C, N) powder, metal binder powder, and grain inhibitor powder weighed in proportion to the high-energy stirring ball mill tank, and add organic dispersant and binding agent, WC grinding balls and solvent, after stirring and milling for 48-72 hours, add chopped polyacrylonitrile pre-oxidized fiber for ball milling for 0.5-2 hours.

[0034] (3) Drying: In a vacuum drying oven, dry the finely ground and evenly mixed slurry at a controlled temperature of 40-100°C, time of 40-60h, and vacuum degree of 0-1Pa.

[0035] (4) Grinding and sieving: Grind the dried powder and select a sieve with a suitable aperture for sieving.

[0036] (5) Loading: put the prepared composite powder into a sinterin...

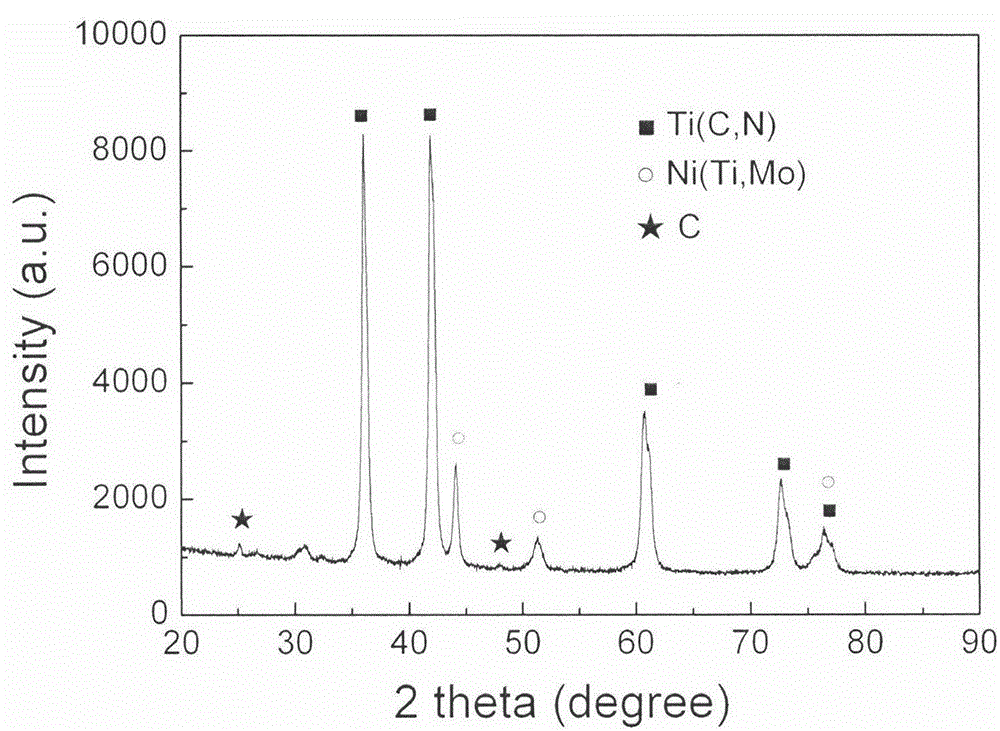

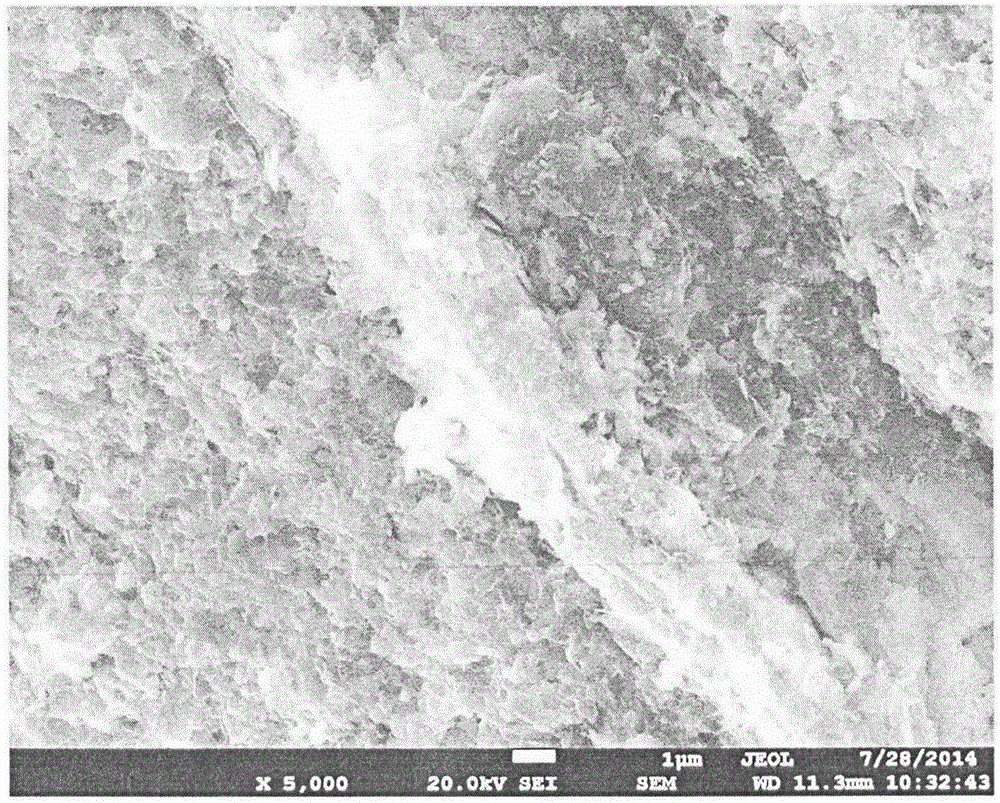

Embodiment 1

[0041] The manufacturing method and technological process of the novel high-performance Ti(C, N)-based cermet of the embodiment of the present invention are as follows:

[0042] (1) Weighing: 80% Ti(C, N) powder by mass fraction, 10% Ni powder, 5% Mo 2 C powder, 5% polyacrylonitrile preoxidized fiber Weigh each reagent.

[0043] (2) Mixing: Put the weighed raw material Ti(C,N) powder, metal binder powder, and grain inhibitor powder into a high-energy stirring ball mill tank, and add 10 times the mass of WC grinding balls and 5 times the mass of quality of absolute ethanol solvent, stirred and ball milled for 71 hours, added chopped polyacrylonitrile pre-oxidized fibers to the slurry, and then ball milled for 0.5 hours.

[0044] (3) Drying: Vacuum drying is adopted, the temperature is controlled at 100°C, the time is 40h, and the vacuum degree is -0.33Pa.

[0045] (4) Grinding and sieving: After grinding the dried powder, select a sieve with an aperture of 1mm to sieve.

[0...

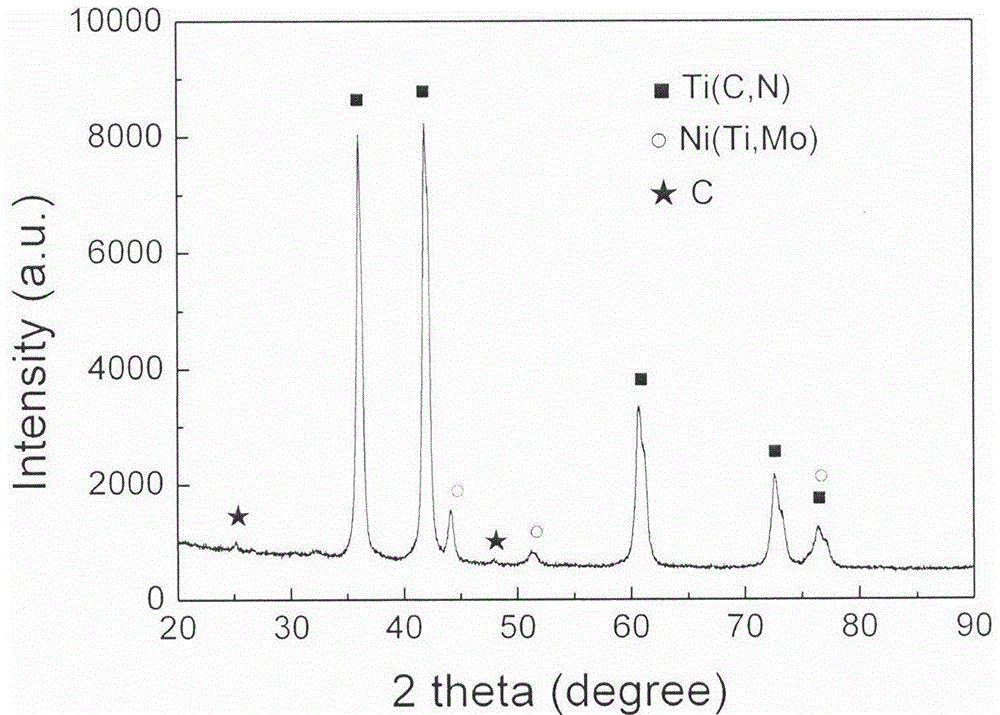

Embodiment 2

[0051] The manufacturing method and technological process of the novel high-performance Ti(C, N)-based cermet of the embodiment of the present invention are as follows:

[0052] 1) Weighing: 60% Ti(C, N) powder by mass fraction, 10% Ni powder, 5% NbC powder, 5% Mo 2 C powder, 20% polyacrylonitrile preoxidized fiber Weigh each reagent, and add 10% organic dispersant and adhesive.

[0053] 2) Mixing: Put the weighed raw material Ti(C,N) powder, metal binder powder, and grain inhibitor powder into a high-energy stirring ball mill tank, and add 10 times the mass of WC grinding balls and 5 times the mass of After stirring and ball milling for 71 hours, add chopped polyacrylonitrile preoxidized fibers to the slurry, and then ball mill for 1.5 hours.

[0054] 3) Drying: Vacuum drying is adopted, the temperature is controlled at 60°C, the time is 48h, and the vacuum degree is -1Pa.

[0055] 4) Grinding and sieving: After grinding the dried powder, select a sieve with an aperture of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com