A kind of aramid fiber paper added with potassium titanate whiskers and preparation method thereof

A technology of potassium titanate whiskers and aramid paper, which is applied in the fields of materials and papermaking, and achieves the effects of high electrical insulation, broad application prospects and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

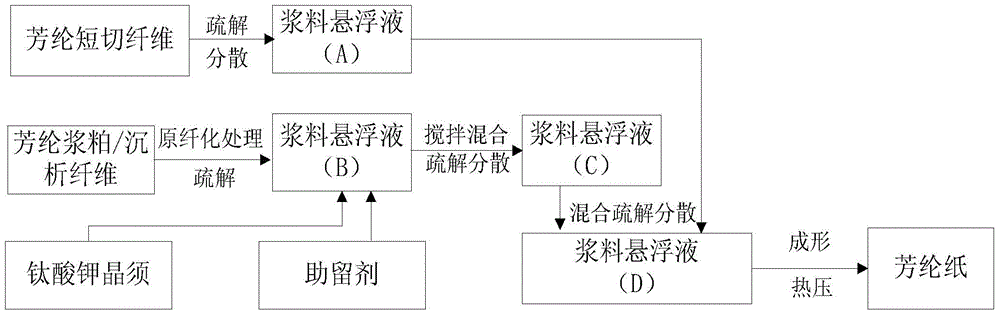

[0044] see figure 1 , a kind of preparation method of the aramid paper that adds potassium titanate whisker, comprises the following steps:

[0045] Step 1: dissolving and dispersing any one of the aramid fiber X, that is, the meta-aramid chopped fiber and the para-aramid chopped fiber, to prepare a slurry suspension (A);

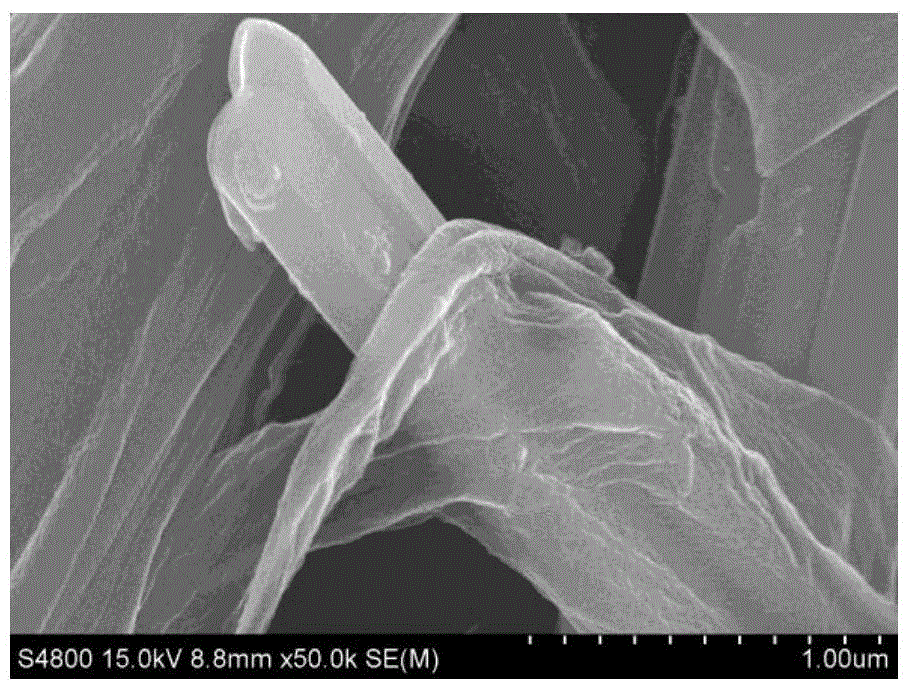

[0046] Step 2: Fibrillating one or more fibers of the aramid fiber Y, that is, the para-aramid fibrid fiber, the para-aramid pulp fiber, and the meta-aramid fibrid fiber, and dissolving and dispersing Obtain slurry suspension (B);

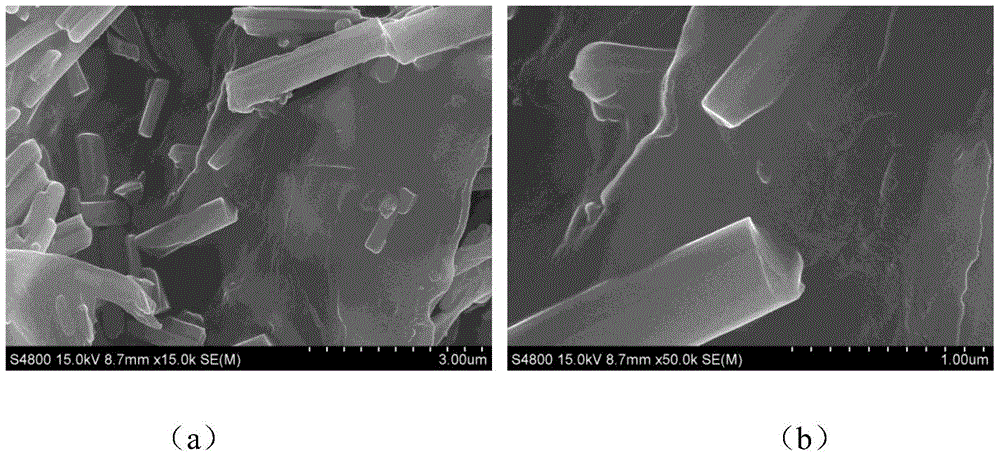

[0047] Step 3: Mix potassium titanate whiskers with the slurry suspension (B) prepared in step 2 to obtain a mixture, wherein the mass concentration of potassium titanate whiskers is 0.5-8%, and then add cationic polypropylene to the mixture Amide, the addition amount is 0.02-0.1% of the dry weight of the fibers in the slurry suspension (B). During the process of adding cationic polyacrylamide, use a stirrer to stir the differ...

Embodiment 1

[0058] Step 1: dissolving and dispersing the aramid fiber X, that is, the meta-aramid chopped fiber, to prepare a pulp suspension (A);

[0059] Step 2: fibrillating and dispersing the aramid fiber Y, that is, the meta-aramid fibrid fiber, to obtain a slurry suspension (B);

[0060] Step 3: Mix potassium titanate whiskers with the slurry suspension (B) prepared in step 2 to obtain a mixture, wherein the mass concentration of potassium titanate whiskers is 1%, and then add cationic polyacrylamide to the mixture, The addition amount is 0.02% of the dry weight of the fibers in the slurry suspension (B). During the process of adding cationic polyacrylamide, stir with a stirrer to fully mix and disperse the different components. The stirring time is 9 minutes, and the stirring speed is controlled at 300rpm, obtained slurry suspension (C);

[0061] Step 4: Mix the slurry suspension (A) prepared in step 1 with the slurry suspension (C) prepared in steps 2 and 3, and control the arami...

Embodiment 2

[0064] Step 1: dissolving and dispersing the aramid fiber X, that is, the para-aramid chopped fiber, to prepare a pulp suspension (A);

[0065] Step 2: fibrillating and dispersing the aramid fiber Y, that is, the para-aramid pulp fiber, to obtain a pulp suspension (B);

[0066] Step 3: Mix potassium titanate whiskers with the slurry suspension (B) prepared in step 2 to obtain a mixture, wherein the mass concentration of potassium titanate whiskers is 1%, and then add cationic polyacrylamide to the mixture, The addition amount is 0.03% of the dry weight of the fibers in the slurry suspension (B). During the process of adding cationic polyacrylamide, stir with a stirrer to fully mix and disperse the different components. The stirring time is 10 minutes, and the stirring speed is controlled at 400rpm, obtained slurry suspension (C);

[0067] Step 4: Mix the slurry suspension (A) prepared in step 1 with the slurry suspension (C) prepared in steps 2 and 3, and control the aramid f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com