Epitaxial layer-based vertical current regulative diode and manufacturing method thereof

A constant current diode, vertical type technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of low breakdown voltage, low constant current, etc., to achieve increased current density, constant current stability, and change slow rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

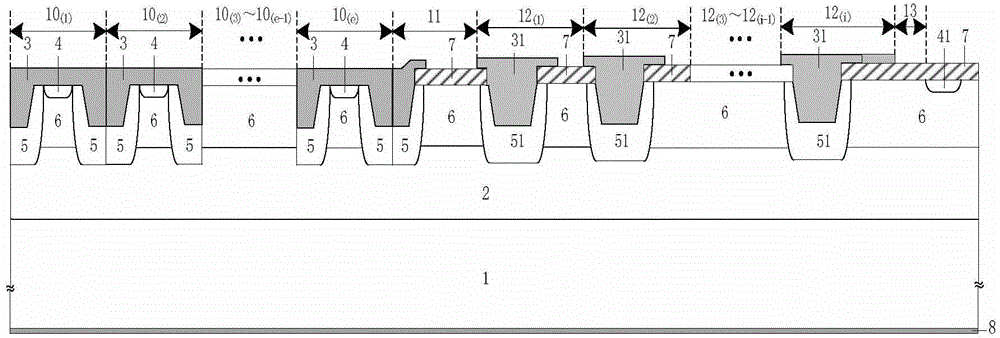

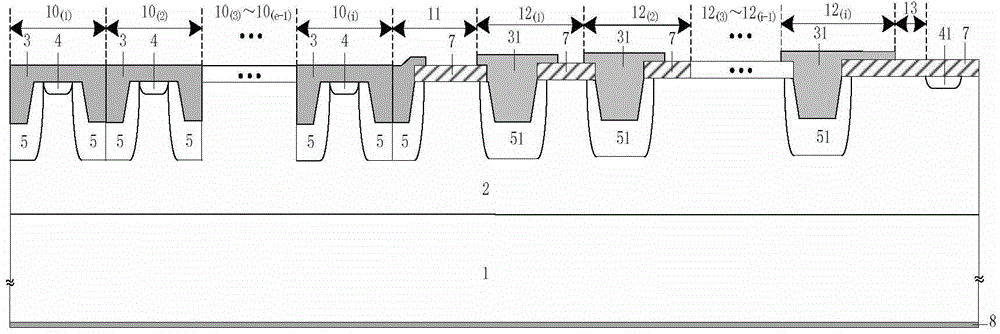

[0058] The breakdown voltage of the vertical constant current diode based on epitaxy described in this embodiment is 200V, the current is 1.5E-5A / μm, the number of cells in the cell structure is 6, and the number of terminals in the terminal structure is 3.

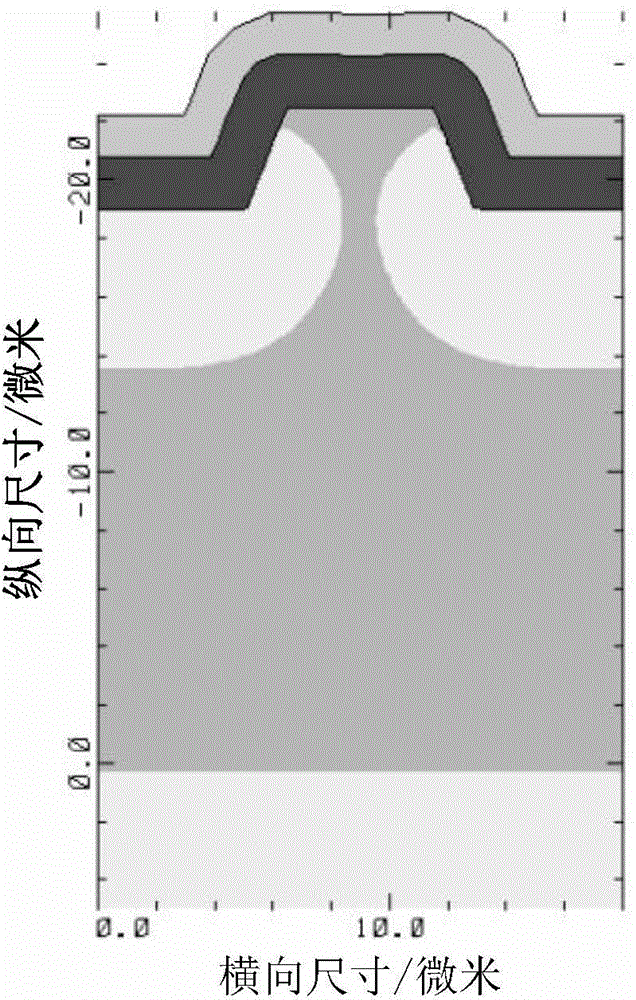

[0059] With the help of MEDICI simulation software provided by figure 1 The shown epitaxy-based vertical constant current diode is used for process simulation. The simulation parameters are: the initial silicon wafer thickness is about 200 μm, and the concentration is 8E14cm -3 ; The thickness of the first lightly doped N-type epitaxial layer 2 is about 16 μm, and the concentration is 1.2E15cm -3 ; The thickness of the second higher doped N-type epitaxial layer 6 is about 7 μm, and the concentration is 5E15cm -3 ; The dose of boron injected is about 4E15cm -2 ; To form a P+ type diffusion region, the dose of phosphorus implanted is 4E15cm -2 An N+ heavily doped region is formed. cell 10 (1) 、10 (2). ...10 (6) The w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com