Thermosetting polymer compound, poly-half-amide supermolecular film and preparation method thereof

A thermosetting and supramolecular technology, applied in the field of thermosetting polysemiamide supramolecular films and their preparation, can solve problems such as inability to recycle, incapable of melting and plasticizing, environmental pollution, etc., achieve excellent mechanical properties, and avoid complex product structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

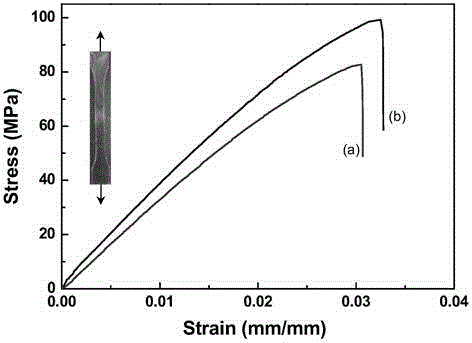

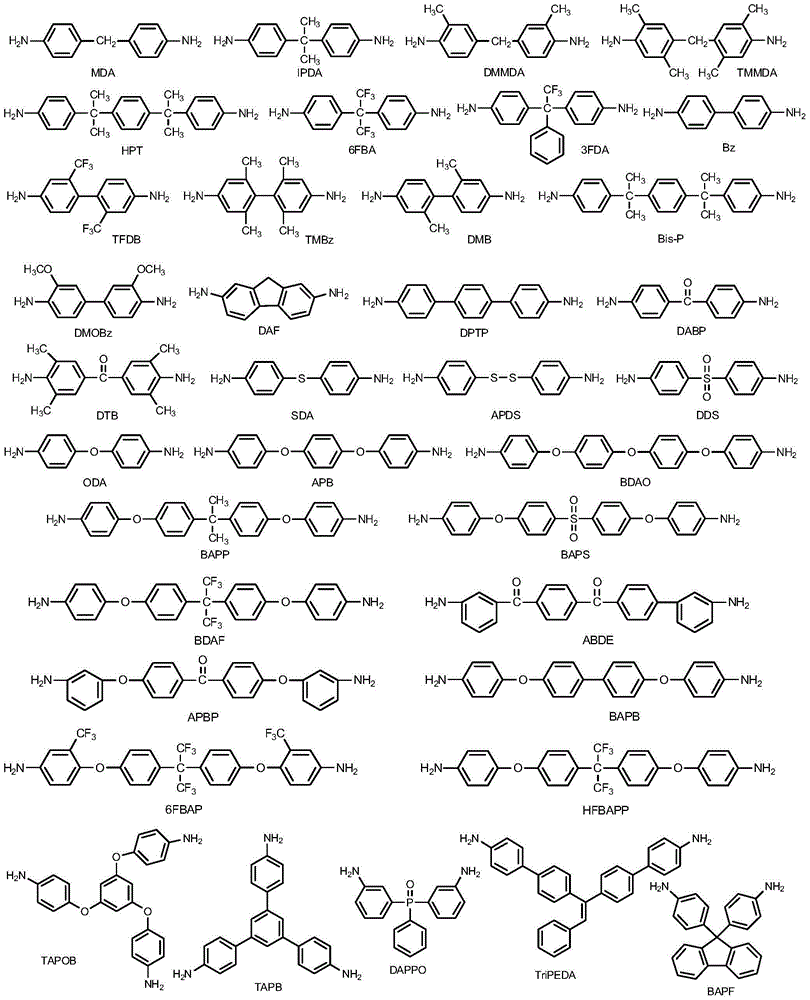

[0032] 16mmol of paraformaldehyde and 8ml of N-methylpyrrolidone / water mixed solvent were prepared into a suspension, stirred and reacted at 80°C for 0.5 hour for depolymerization, and cooled to room temperature to obtain a formaldehyde reaction liquid. Dissolve 8 mmol of aromatic diamine BAPP in 4 ml of N-methylpyrrolidone to obtain an aromatic amine reaction liquid. Mix the reaction solution of formaldehyde and aromatic amine evenly (the volume content of water in the mixed solvent of the final reaction system is 5%), stir and react at 50°C for 30 minutes for pre-polymerization, further spread film on a horizontal glass plate, and dry at 50°C After 24 hours, the target product was obtained as a colorless transparent film. The light transmittance is 94%, Young's modulus, tensile strength, elongation at break and tensile energy at break are respectively 3.8GPa, 82.7MPa, 3.1%, 1.3MJ / m 3 (See figure 1 , film dumbbell tensile specimen and representative stress-strain curve (a))...

Embodiment 2

[0034] 10mmol of paraformaldehyde and 10ml of dimethylformamide / water mixed solvent were prepared into a suspension, stirred and reacted at 100°C for 0.1 hour for depolymerization, and cooled to room temperature to obtain a formaldehyde reaction liquid. Dissolve 5 mmol of aromatic diamine MDA in 10 ml of dimethylformamide to obtain an aromatic amine reaction solution. Mix the formaldehyde and aromatic amine reaction solution evenly (the volume content of water in the mixed solvent of the final reaction system is 10%), stir and react at 80°C for 3 minutes for pre-polymerization, further spread film on a horizontal glass plate, and dry at 40°C After 48 hours, the target product was obtained as a colorless transparent film. The light transmittance is 97%, Young's modulus, tensile strength, elongation at break and tensile energy at break are respectively 5.7GPa, 72.5MPa, 2.4%, 0.87MJ / m 3 . After soaking each gram of film in 10ml, 0.5mol / L hydrochloric acid for 6 hours, neutraliz...

Embodiment 3

[0036] 8 mmol of paraformaldehyde and 15 ml of dimethyl sulfoxide / water mixed solvent were prepared into a suspension, stirred and reacted at 60° C. for 2 hours for depolymerization, and cooled to room temperature to obtain a formaldehyde reaction liquid. Dissolve 4 mmol of aromatic diamine DPTP in 4 ml of dimethyl sulfoxide to obtain an aromatic amine reaction solution. Mix the formaldehyde and aromatic amine reaction liquid evenly (the volume content of water in the mixed solvent in the final reaction system is 15%), stir and react at 65°C for 5 minutes for pre-polymerization, further spread film on a horizontal glass plate, and dry at 80°C After 12 hours, the target product was obtained as a colorless transparent film. The light transmittance is 96%, Young's modulus, tensile strength, elongation at break and tensile energy at break are respectively 3.5GPa, 96.7MPa, 3.4%, 1.7MJ / m 3 . After soaking each gram of film in 15ml, 0.8mol / L nitric acid for 10 hours, and then neutr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com