Preparation method of PVC modified sheet

A sheet and modification technology, applied in the field of preparation of weather-resistant PVC sheet products, can solve the problems of breakage, easy rupture of PVC sheets, and easy aging, and achieve the effects of easy molding process, not easy to break, and not easy to age.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

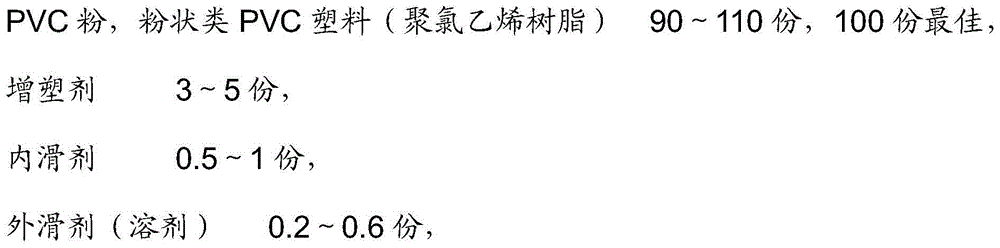

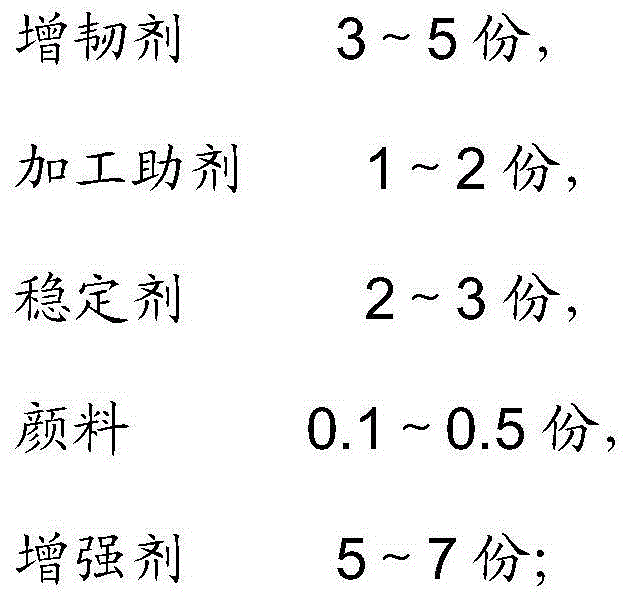

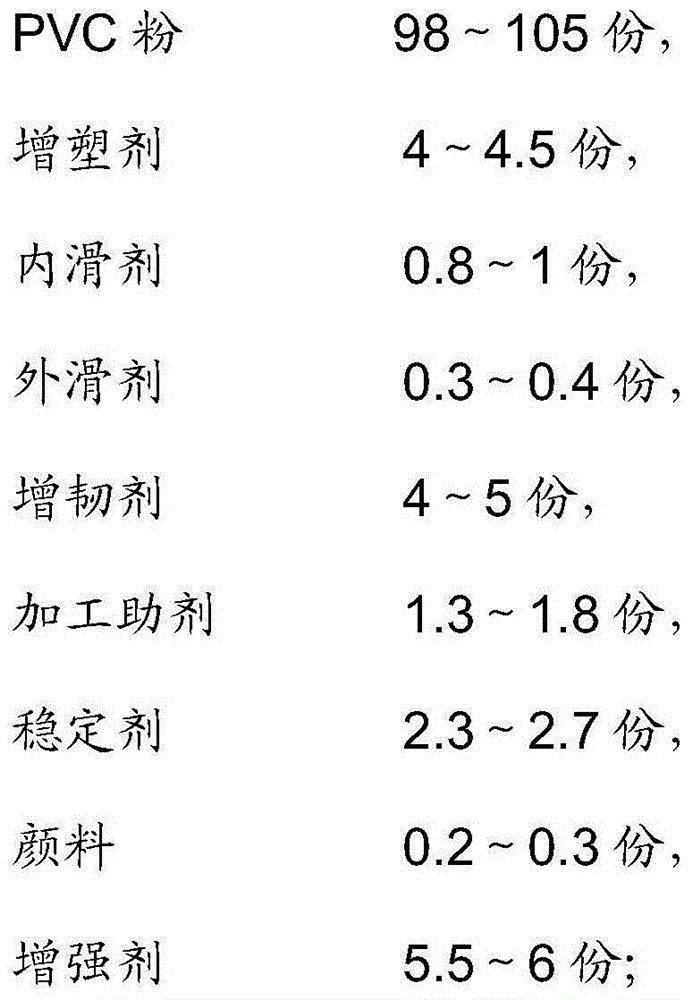

[0060] (1) Prepare raw materials according to the following formula: 100 parts of PVC powder, 3.5 parts of dioctyl terephthalate (DOTP), 0.6 parts of n-butyl stearate, 0.3 parts of methyl hydrogen sulfate, 3.5 parts of polyethylene, acrylate 1.2 parts of resin (ACR resin), 2.2 parts of methyl tin mercaptide, 0.2 parts of pigment, 5.5 parts of methacrylic acid (MBS resin: methyl methacrylate-butadiene-styrene copolymer);

[0061] Drying of raw materials: drying at 115°C for 2.5 hours, then set aside;

[0062] (2) Add the dried raw materials into the mixer, mix and stir at high speed for 8 minutes, mixing order: powdery PVC plastic, dioctyl terephthalate (DOTP), methyl tin mercaptide, polyethylene , methyl hydrogen sulfate, acrylate resin (ACR resin), pigment, polyethylene, methacrylic acid (MBS resin); high-speed mixing to obtain a premix;

[0063] (3), the premix is cooled to 48°C;

[0064] (4) Extrusion: Add the premixed material after cooling in step (3) into the extrude...

Embodiment 2

[0071] (1) Prepare raw materials according to the following formula: 107 parts of PVC powder, 4.3 parts of dioctyl terephthalate (DOTP), 0.8 part of n-butyl stearate, 0.5 part of nitrile rubber, 4.5 parts of polyethylene, acrylate resin (ACR resin) 1.9 parts, mercaptan methyl tin 2.8 parts, pigment 0.4 parts, methacrylic acid (MBS resin: methyl methacrylate-butadiene-styrene copolymer) 6.5 parts;

[0072] Drying of raw materials: drying at 122°C for 3.5 hours, set aside;

[0073] (2) Add the dried raw materials into the mixer, mix and stir at high speed for 6 minutes, mixing sequence: powdery PVC plastic (polyvinyl chloride resin), plasticizer, stabilizer, internal and external slip agent, Processing aids, pigments, tougheners, reinforcing agents; high-speed mixing to obtain premixes;

[0074] (3), the premix is cooled to 50°C;

[0075] (4) Extrusion: Add the premixed material after cooling in step (3) into the extruder through the feeder, extrude through the extruder, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com