Acid-proof ink for protecting integrated touch screen and preparation method of acid-proof ink

A technology for acid-resistant inks and touch screens, applied in inks, applications, household appliances, etc., can solve problems such as low yield rate, difficult film removal, and damage to sensors, so as to improve acid resistance, facilitate coating, and improve peelability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0049] Prepare polystyrene-polyurethane-unsaturated polyester resin, the preparation method is as follows:

[0050] Step (1): Synthesis of unsaturated polyester containing terminal hydroxyl groups

[0051] In a four-port reaction vessel with stirring and condensation, 30 parts of tetrachlorophthalic acid, 30 parts of tetrabromophthalic acid, 35 parts of octadecanedioic acid, 45 parts of mesaconic acid, 15 parts of butyric acid Alkenic anhydride, 15 parts of hexachloromethylene phthalic anhydride, 60 parts of trimethylpentanediol, 55 parts of 2-ethyl-2-butyl-1,3-propanediol, 0.3 parts of catalyst, 150 parts part solvent, blow nitrogen and stir, slowly raise the temperature to 125°C, maintain for 2h, then gradually raise the temperature to 165°C and continue the reaction for 3h until the acid value is close to or reaches 40mgKOH / g, continue to add 2-ethyl-2-butyl-1 , 3-propanediol, reacted for 1h, the acid value of the straight system was less than 10mgKOH / g, and when the water...

Embodiment 1

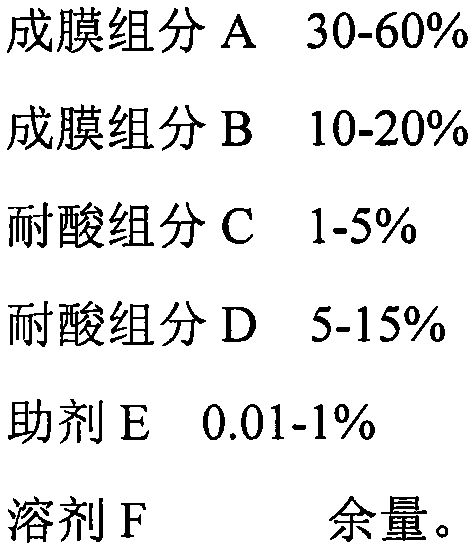

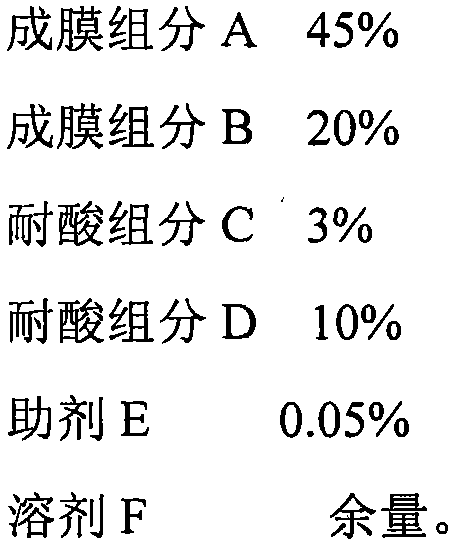

[0058] An acid-resistant ink for protecting an integrated touch screen, which consists of the following components by mass percentage:

[0059]

[0060] Wherein, the composition of film-forming component A is:

[0061] 60 parts of polystyrene-polyurethane-unsaturated polyester resin; 15 parts of chlorinated polyolefin modified by maleic anhydride grafting; 35 parts of carboxyl-modified terpolymer of chlorinated vinegar; silicone-modified EPDM 40 parts of rubber;

[0062] The film-forming component B consists of: cellulose acetate butyrate, 20 parts; epoxy resin, 5 parts, and blocked polyurethane, 25 parts;

[0063] Acid resistant component C is N-(2-aminoethyl)-3-aminopropyltriethoxysilane, 3-isocyanatopropyltriethoxysilane, β-(3,4-epoxycyclohexyl) Ethyltrimethoxysilane is a mixture of 1:1:1 according to the mass ratio;

[0064] Acid-resistant component D is nano-alumina;

[0065] Auxiliary E is iron acetylacetonate;

Embodiment 2

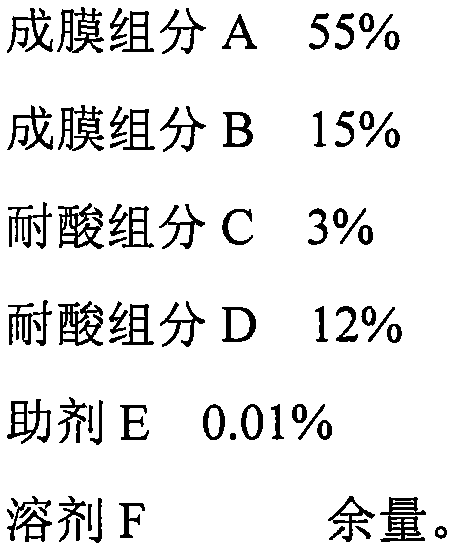

[0071] An acid-resistant ink for protecting an integrated touch screen, which consists of the following components by mass percentage:

[0072]

[0073] Wherein, the composition of film-forming component A is:

[0074] 50 parts of polystyrene-polyurethane-unsaturated polyester resin; 20 parts of maleic anhydride graft-modified chlorinated polyolefin; 35 parts of carboxyl-modified terpolymer of chlorinated vinegar; silicone-modified EPDM 30 parts of rubber;

[0075] The film-forming component B consists of: cellulose acetate butyrate, 25 parts; epoxy resin, 10 parts, and closed polyurethane, 20 parts;

[0076] Acid resistant component C is N-(2-aminoethyl)-3-aminopropyltriethoxysilane, 3-isocyanatopropyltriethoxysilane, β-(3,4-epoxycyclohexyl) Ethyltrimethoxysilane is a mixture of 1: 1.5: 2 according to the mass ratio;

[0077] Acid-resistant component D is nano-alumina;

[0078] Auxiliary E is nickel acetylacetonate;

[0079] Described solvent F is the mixture (mass ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com