ldmos device and manufacturing method

A device and manufacturing process technology, applied in the field of LDMOS device manufacturing, can solve problems such as low on-resistance, reduce device breakdown voltage, etc., achieve large on-resistance, increase breakdown voltage, and reduce on-resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

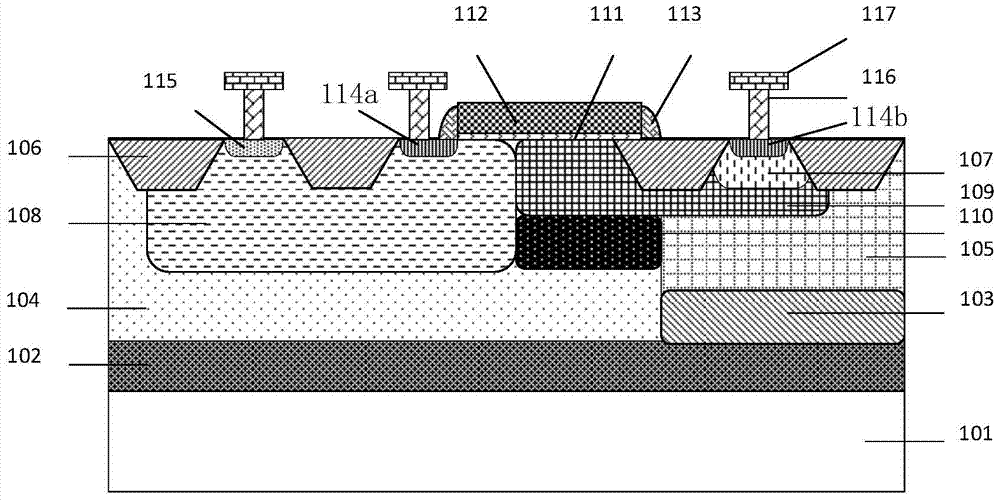

[0048] figure 1 It is a schematic structural diagram of an LDMOS device in an embodiment of the present invention; the LDMOS device in an embodiment of the present invention is an N-type LDMOS device, including:

[0049] The N+ buried layer 102 is formed on the P-type silicon substrate 101 .

[0050] The P+ buried layer 103 is formed on a part of the N+ buried layer 102 , and the bottom of the P+ buried layer 103 is in contact with the N+ buried layer 102 .

[0051] The N-type epitaxial layer 104 is formed on the surface of the silicon substrate 101 , and the bottom of the N-type epitaxial layer 104 is respectively in contact with the N+ buried layer 102 and the P+ buried layer 103 .

[0052] The P-type diffusion layer 105 is formed in the N-type epitaxial layer 104 on the top of the P+ buried layer 103, and the P-type impurities of the P-type diffused layer 105 are transferred from the P+ buried layer 103 to the N-type epitaxial layer. Diffusion formation in 104.

[0053] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com