Method for preparing chelating fiber material capable of adsorbing heavy metals in water

A technology for chelating fibers and heavy metals, which is applied in the fields of adsorption water/sewage treatment, fiber treatment, chemical instruments and methods, etc., can solve the problems of poor mechanical properties of PP chelated fibers, high process energy consumption, and high reaction temperature. The chelation capacity is controllable, the process is simple, and the process is mild.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

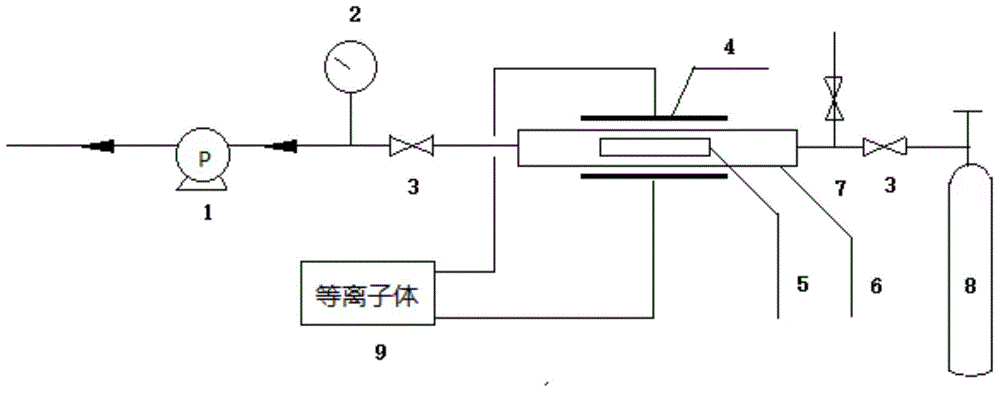

[0039] (1) Soak and wash the PP fiber material with acetone for 10 hours, centrifugally spin dry, and dry to obtain the pretreated PP fiber material, which is put into a plasma reactor (see figure 1 )middle. Vacuumize the plasma reactor, then feed argon into the reactor and then evacuate to vacuum, and replace the air in the reactor 5 times to ensure that the reactor is an argon atmosphere. After preheating the plasma generator device for 10 minutes, control the argon flow rate through the valve, turn on the radio frequency generator of the plasma generator device, set the plasma atmosphere pressure to 15Pa, discharge power to 15w, and discharge time to 3min to obtain Surface activated PP fibers.

[0040] (2) Pass the obtained surface-activated PP fiber into air through the vent tube, and leave it at room temperature for 1 hour to allow the peroxidation reaction to be sufficient to obtain PP fibers with peroxy groups on the surface.

[0041] (3) The PP fiber material that th...

Embodiment 2

[0046] (1) Soak and wash the PP fiber material with acetone for 10 hours, centrifugally spin dry, and dry to obtain the pretreated PP fiber material, which is put into a plasma reactor (see figure 1 .)middle. Vacuumize the plasma reactor, then feed argon into the reactor and then evacuate to vacuum, and replace the air in the reactor 5 times to ensure that the reactor is an argon atmosphere. After preheating the plasma generator device for 10 minutes, control the argon flow rate through the valve, turn on the radio frequency generator of the plasma generator device, set the plasma atmosphere pressure to 15Pa, discharge power to 20w, and discharge time to 3min to obtain Surface activated PP fibers.

[0047] (2) Pass the obtained surface-activated PP fiber into air through the vent tube, and leave it at room temperature for 1 hour to allow the peroxidation reaction to be sufficient to obtain PP fibers with peroxy groups on the surface.

[0048] (3) The PP fiber material that t...

Embodiment 3

[0053] (1) Soak and wash the PP fiber material with acetone for 10 hours, centrifugally spin dry, and dry to obtain the pretreated PP fiber material, which is put into a plasma reactor (see figure 1 .)middle. Vacuumize the plasma reactor, then feed argon into the reactor and then evacuate to vacuum, and replace the air in the reactor 5 times to ensure that the reactor is an argon atmosphere. After preheating the plasma generator device for 10 minutes, control the argon flow rate through the valve, turn on the radio frequency generator of the plasma generator device, set the plasma atmosphere pressure to 15Pa, discharge power to 20w, and discharge time to 3min to obtain Surface activated PP fibers.

[0054] (2) Pass the obtained surface-activated PP fiber into air through the vent tube, and leave it at room temperature for 1 hour to allow the peroxidation reaction to be sufficient to obtain PP fibers with peroxy groups on the surface.

[0055] (3) The PP fiber material that t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturated adsorption capacity | aaaaa | aaaaa |

| Saturated adsorption capacity | aaaaa | aaaaa |

| Saturated adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com