ABS composite flame resistant material and preparation method thereof

A technology of compound flame retardant and thermal stabilizer, applied in the field of polymer materials, can solve the problems of low thermal deformation temperature, poor physical and mechanical properties, poor thermal stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

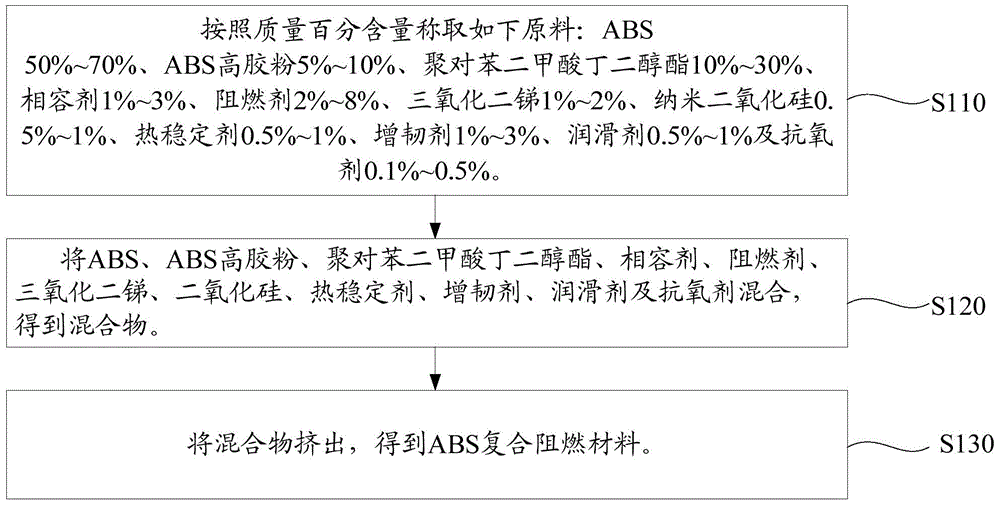

[0043] Such as figure 1 As shown, a method for preparing an ABS composite flame retardant material can be used to prepare the above ABS composite flame retardant material. The preparation method of ABS composite flame retardant material includes the following steps:

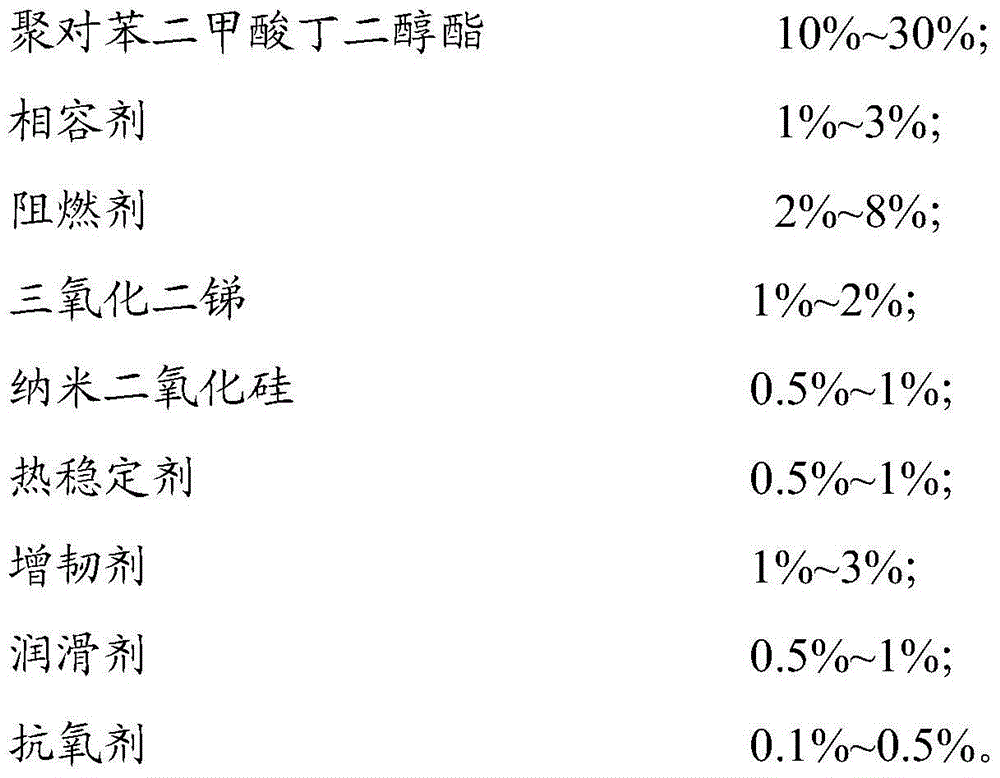

[0044] Step S110: Weigh the following raw materials according to the mass percentage: ABS 50%~70%, ABS high rubber powder 5%~10%, polybutylene terephthalate 10%~30%, compatibilizer 1% ~3%, flame retardant 2%~8%, antimony trioxide 1%~2%, nano silica 0.5%~1%, heat stabilizer 0.5%~1%, toughening agent 1%~3% , Lubricant 0.5% to 1% and antioxidant 0.1% to 0.5%.

[0045] The compatibilizer is selected from methyl methacrylate-glycidyl methacrylate-ethyl acrylate terpolymer (MGE), ABS graft, styrene-acrylonitrile-glycidyl methacrylate (SAG) ) And one of styrene-maleic anhydride copolymer (SMA).

[0046] Among them, the graft of ABS may be ABS-g-MAH (maleic anhydride grafted with ABS).

[0047] The mass percentage of butadie...

Embodiment 1

[0065] The preparation steps of the ABS composite flame-retardant material of this embodiment are as follows:

[0066] (1) Weigh the following components according to the mass percentage:

[0067]

[0068] (2) Mix ABS and ABS high rubber powder to obtain ABS composite powder. Among them, the mass percentage of butadiene in the ABS high rubber powder is 55%, and the ABS composite powder is based on the mass percentage and the particle size is 100-200 nanometer particles account for 50%, and particles with a particle diameter of 300-400 nanometers account for 50%; then use a high-speed mixer to mix ABS composite powder, PBT, decabromodiphenylethane, antimony trioxide, and nano silica , Tribasic lead sulfate, MGE, polyethylene wax, antioxidant 1010 and nitrile rubber are stirred and mixed to obtain a mixture.

[0069] (3) Extrude the mixture in a twin-screw extruder with a rotation speed of 450 revolutions per minute. Among them, the temperature in the first zone of the extruder is 25...

Embodiment 2

[0072] The preparation steps of the ABS composite flame-retardant material of this embodiment are as follows:

[0073] (1) Weigh the following components according to the mass percentage:

[0074]

[0075] (2) Mix ABS and ABS high rubber powder to obtain ABS composite powder, where the mass percentage of butadiene in the ABS high rubber powder is 70%, and the ABS composite powder has a particle size of 70% by mass. 100-200 nanometer particles account for 40%, and particles with a particle diameter of 300-400 nanometers account for 60%; use a high-speed mixer to mix ABS composite powder, PBT, decabromodiphenylethane, antimony trioxide, nano silica, Tribasic lead sulfate, MGE, polyethylene wax, antioxidant 1010 and nitrile rubber are stirred and mixed to obtain a mixture.

[0076] (3) Extrude the mixture in a twin-screw extruder with a rotation speed of 450 revolutions per minute. Among them, the temperature in the first zone of the extruder is 255°C, the temperature in the second zo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Heat distortion temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com