Method for measuring octyl phenol by virtue of electrochemical sensor

An octylphenol and sensor technology, applied in the field of electrochemistry, to achieve the effect of improving photocatalytic efficiency, broadening the response range, and enhancing interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Ni-g-C 3 N 4 Preparation of modified electrodes:

[0019] Weigh 49mgNiCl 2 ·6H 2 O powder in a small beaker, a small amount of ultrapure water ultrasonically dissolved, add 3 g of melamine to the above solution, continue ultrasonic stirring to dissolve evenly, then transfer to a ceramic crucible, after heating and stirring evenly, put it into a muffle furnace for heating, the heating rate is 5 ℃ / min, heating temperature 520 ℃, constant temperature 4h, after cooling, yellow Ni-g-C 3 N 4 powder.

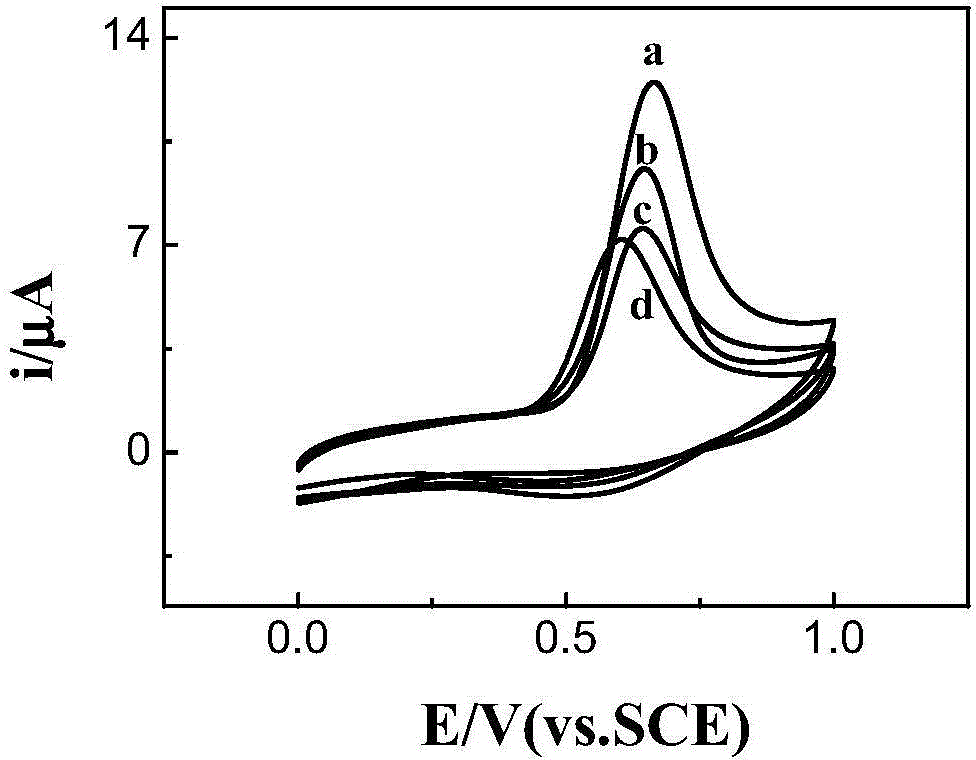

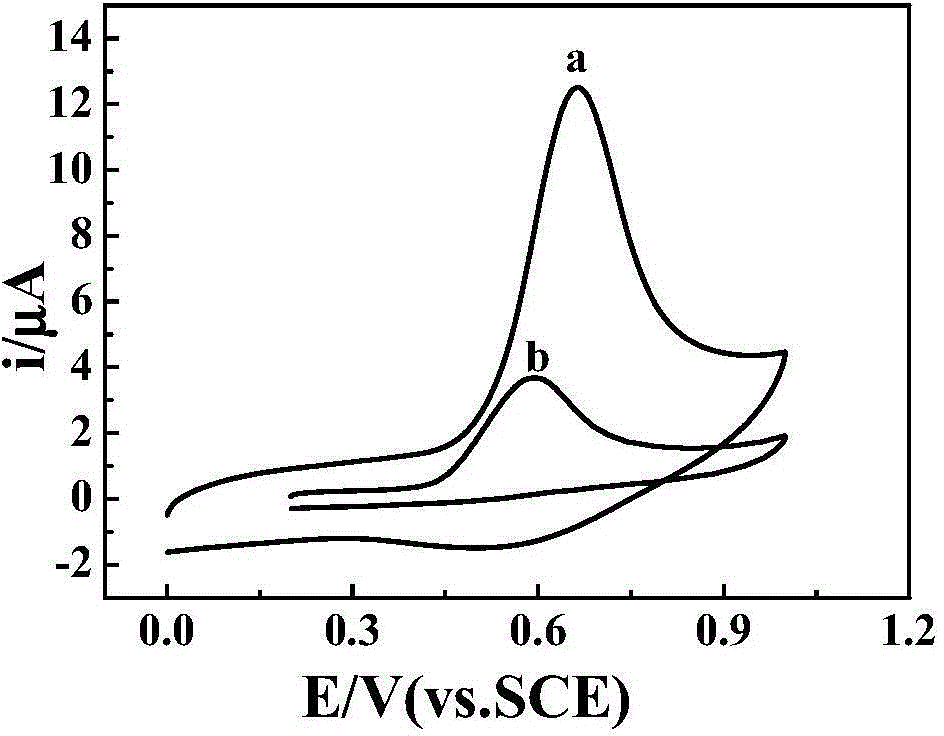

[0020] 4mgNi-g-C 3 N 4 The powder was added to 4mL DMF, and ultrasonically dispersed to obtain Ni-g-C 3 N 4 / DMF dispersion, for later use. 0.05μm Al for glassy carbon electrode 2 o 3 Slurry was polished, rinsed and washed in twice distilled water, absolute ethanol, HNO 3 (1:1, V / V) solution was ultrasonically cleaned for 1 min, and dried under an infrared lamp for later use. Pipette 5 μL Ni-g-C 3 N 4 / DMF dispersion, drop-coated on the surface of the glassy carb...

Embodiment 2

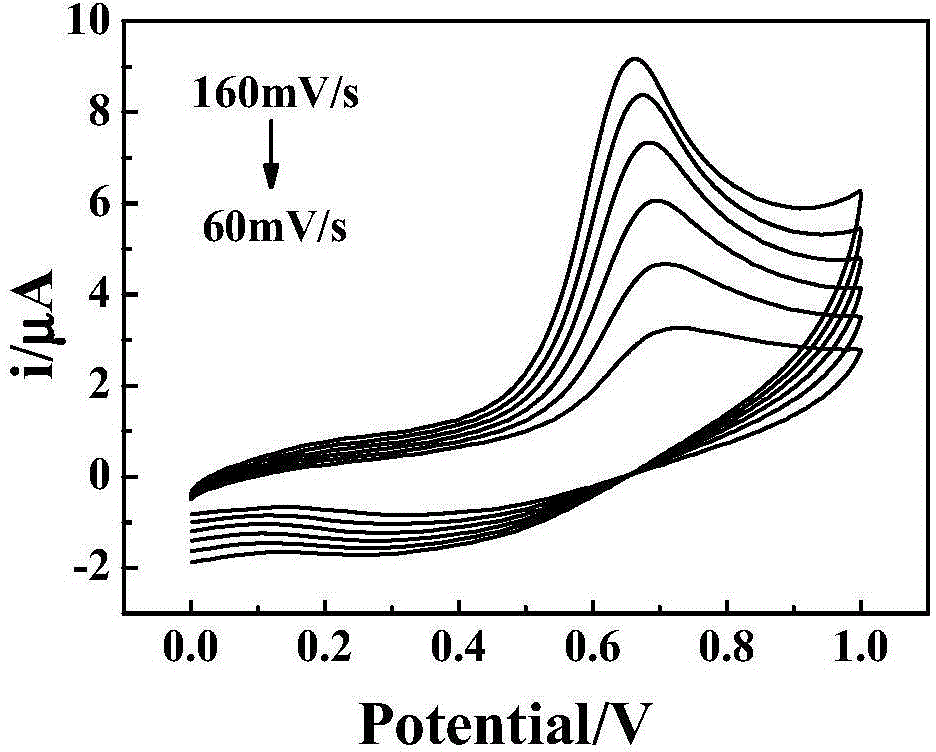

[0027] Ni-g-C 3 N 4 The preparation of the modified electrode is the same as in Example 1. The modified electrode is placed in a 0.1% sodium chloride (pH=7.0) buffer system containing the analyte, and after being irradiated by an infrared lamp (220V, 250W) for 3 minutes, a cyclic voltammetry scan is performed. (CV), differential pulse method (DPV) scanning, the scanning speed is 100mV / s, by measuring the current intensity corresponding to the electrocatalytic oxidation peak of octylphenol, determine the content of octylphenol. The rest of the steps are the same as in Example 1.

Embodiment 3

[0029] Ni-g-C 3 N 4The preparation of the modified electrode is the same as in Example 1, the modified electrode is put into the pH of 5.8-8.0 phosphate buffer containing the test substance, and after 3 minutes of irradiation by an infrared lamp (220V, 250W), a cyclic voltammetry scan (CV) is performed And differential pulse method (DPV) scanning, the scanning speed is 100mV / s, by measuring the current intensity corresponding to the electrocatalytic oxidation peak of octylphenol, determine the content of octylphenol. Its optimum pH value is 5.8, the highest sensitivity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com