4H-SiC metal-semiconductor field effect transistor with double-sunken buffer layer

A field-effect transistor and metal-semiconductor technology, which is applied in the field of 4H-SiC metal-semiconductor field-effect transistors, can solve the problems that the saturation leakage current has not been substantially improved, the drain current is reduced, and the saturation current is degraded, so as to avoid the breakdown voltage Effects of sharp drop, increase in saturation leakage current, and increase in drain current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

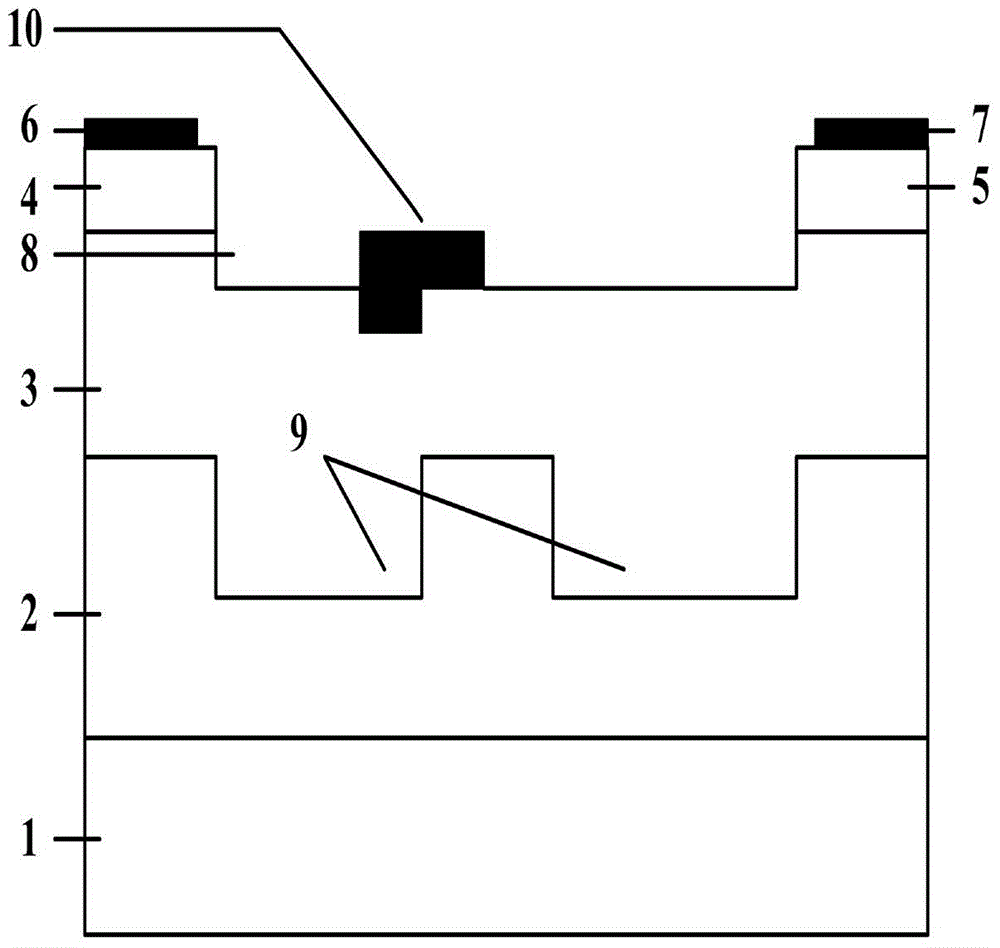

[0028] The production thickness is A 4H-SiC metal-semiconductor field-effect transistor with a thickness of 0.25 μm, starting from the inner side of the source cap layer and the drain cap layer, and a double-recessed buffer layer with a length of 0.85 μm and 0.8 μm respectively.

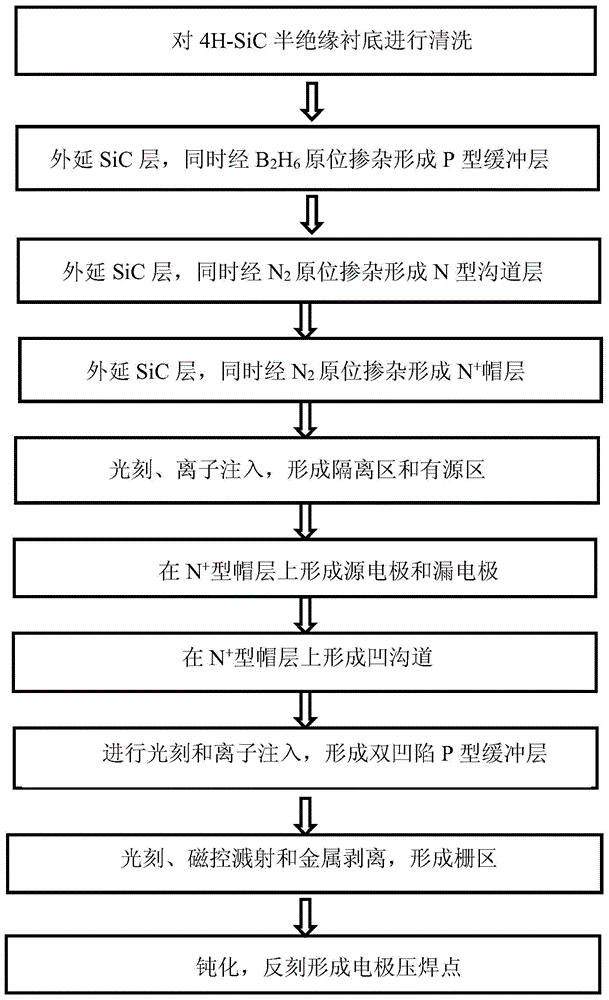

[0029] The manufacturing steps of this embodiment are as follows:

[0030] Step 1: cleaning the 4H-SiC semi-insulating substrate 1 to remove surface pollutants.

[0031] (1) The substrate was carefully cleaned twice with a cotton ball dipped in methanol to remove SiC particles of various sizes on the surface;

[0032] (2) Place 4H-SiC semi-insulating substrate 1 in H 2 SO 4 :HNO 3 = Ultrasound for 5 minutes in 1:1;

[0033] (3) Put the 4H-SiC semi-insulating substrate 1 in 1# cleaning solution (NaOH:H 2 o 2 :H 2 O=1:2:5), boiled for 5 minutes, rinsed with deionized water for 5 minutes, and then put into 2# cleaning solution (HCl:H 2 o 2 :H 2 O=1:2:7) and boiled for 5 minutes. Finally rin...

Embodiment 2

[0070] The production thickness is And a 4H-SiC metal semiconductor field effect transistor with a thickness of 0.2 μm, starting from the inner side of the source cap layer and the drain cap layer, and a double recessed buffer layer with a length of 0.85 μm and 0.8 μm respectively. In the manufacturing steps of this embodiment:

[0071] Step 8: performing a photolithography and ion implantation to form a double recessed P-type buffer layer 9 .

[0072] (1) Positive photoresist is used, glue coating speed: 3000R / min, glue thickness Ensure that it can play a good blocking role in the subsequent isolation injection;

[0073] (2) After gluing is completed, pre-bake in an oven at 90°C for 90 seconds, and use a double-depressed buffer layer photolithography plate for about 35 seconds of UV exposure in a special developer solution (tetramethylammonium hydroxide: water = 1:3) Develop for 60 seconds, then post-bake in an oven at 100°C for 3 minutes;

[0074] (3) Perform nitrogen ...

Embodiment 3

[0078] The production thickness is And a 4H-SiC metal semiconductor field effect transistor with a thickness of 0.3 μm, starting from the inner side of the source cap layer and the drain cap layer, and a double recessed buffer layer with a length of 0.85 μm and 0.8 μm respectively. In the manufacturing steps of this embodiment:

[0079] Step 8: performing a photolithography and ion implantation to form a double recessed P-type buffer layer 9 .

[0080] (1) Positive photoresist is used, glue coating speed: 3000R / min, glue thickness Ensure that it can play a good blocking role in the subsequent isolation injection;

[0081] (2) After gluing is completed, pre-bake in an oven at 90°C for 90 seconds, and use a double-depressed buffer layer photolithography plate for about 35 seconds of UV exposure in a special developer solution (tetramethylammonium hydroxide: water = 1:3) Develop for 60 seconds, then post-bake in an oven at 100°C for 3 minutes;

[0082] (3) Perform nitrogen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com