A kind of rose ginger milk beverage and preparation method thereof

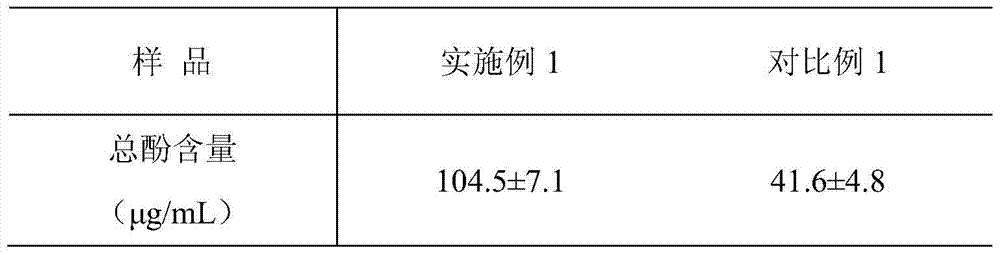

A technology for a milk beverage and rose ginger is applied to the field of rose ginger milk beverage and its preparation, and can solve the problems that the combination of phenolic substances and milk proteins cannot be effectively avoided, the storage stability of the beverage is not good enough, and the content of biologically active components is decreased, and the like, and the invention is achieved. It is not easy to be damaged by oxidation, improves endocrine, and enhances the effects of regulating menstruation and stomach.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033]In this embodiment, the components of the rose ginger milk drink raw materials and the parts by weight of each component are: ginger 4kg, milk powder 1kg, rose 0.5kg, brown sugar 2kg, white sugar 7kg, pitted red dates 0.1kg, longan meat 0.2kg , wolfberry 0.02kg, emulsifying thickener diacetyl tartaric acid mono-diglyceride 0.1kg, embedding agent sodium alginate 0.3kg, deionized water 101kg.

[0034] The preparation method is as follows:

[0035] (1) Weigh 4kg of ginger, 0.5kg of roses, 0.1kg of pitted red dates, 0.2kg of longan meat and 0.02kg of wolfberry, and grind them to a particle size of 0.2-0.5cm with a tissue grinder, and mix the crushed raw materials evenly , add 26kg of deionized water, stir evenly to form a solid-liquid mixture, adjust the pH value of the solid-liquid mixture to 4 with lactic acid, soak at 30°C for 20min, then raise the temperature to 100°C for leaching for 1h, filter, collect the filtrate and pour it into the filter residue Add 40kg of deion...

Embodiment 2

[0039] In the present embodiment, the components of the rose ginger milk beverage raw materials and the parts by weight of each component are: 1 kg of ginger, 4 kg of milk powder, 2 kg of roses, 5 kg of brown sugar, 5 kg of white sugar, 1 kg of pitted red dates, 1 kg of longan meat, and 0.2 kg of wolfberry. kg, emulsifying thickener sodium stearoyl lactylate 0.5kg, embedding agent gelatin 0.1kg, deionized water 107kg.

[0040] The preparation method is as follows:

[0041] (1) Weigh 1kg of ginger, 2kg of roses, 1kg of pitted red dates, 1kg of longan meat and 0.2kg of Chinese wolfberry, grind them to a particle size of 0.4-0.8cm with a tissue grinder, mix the crushed raw materials evenly, and add 20kg In deionized water, stir evenly to form a solid-liquid mixture, adjust the pH value of the solid-liquid mixture to 6 with malic acid, soak at 30°C for 30min, then raise the temperature to 100°C for 1h extraction, filter, collect the filtrate and add to the filter residue 30kg of ...

Embodiment 3

[0045] In the present embodiment, the components of the rose ginger milk drink raw materials and the parts by weight of each component are: ginger 8kg, milk powder 8kg, rose 1kg, brown sugar 8kg, white sugar 3kg, pitted red dates 0.5kg, longan meat 0.5kg, Lycium barbarum 0.1kg, emulsifying thickener sodium tripolyphosphate 0.8kg, embedding agent 2-hydroxypropyl-β-cyclodextrin 0.8kg, deionized water 99kg.

[0046] The preparation method is as follows:

[0047] (1) Weigh 8kg of ginger, 1kg of roses, 0.5kg of pitted red dates, 0.5kg of longan meat and 0.1kg of wolfberry, and grind them to a particle size of 0.6-1cm with a tissue grinder, mix the crushed raw materials evenly, and add 30kg of deionized water, stirred evenly to form a solid-liquid mixture, adjusted the pH value of the solid-liquid mixture to 5 with tartaric acid, soaked at 20°C for 10min, then raised the temperature to 80°C for 3h, filtered, collected the filtrate and added to the filter residue 23kg of deionized w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com