A kind of scr catalyst harmless treatment method

A technology of SCR catalyst and harmless treatment, which is applied in the direction of catalyst regeneration/reactivation, chemical instruments and methods, physical/chemical process catalysts, etc. Large arable land, groundwater pollution and other problems, to achieve good results in terms of economy and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

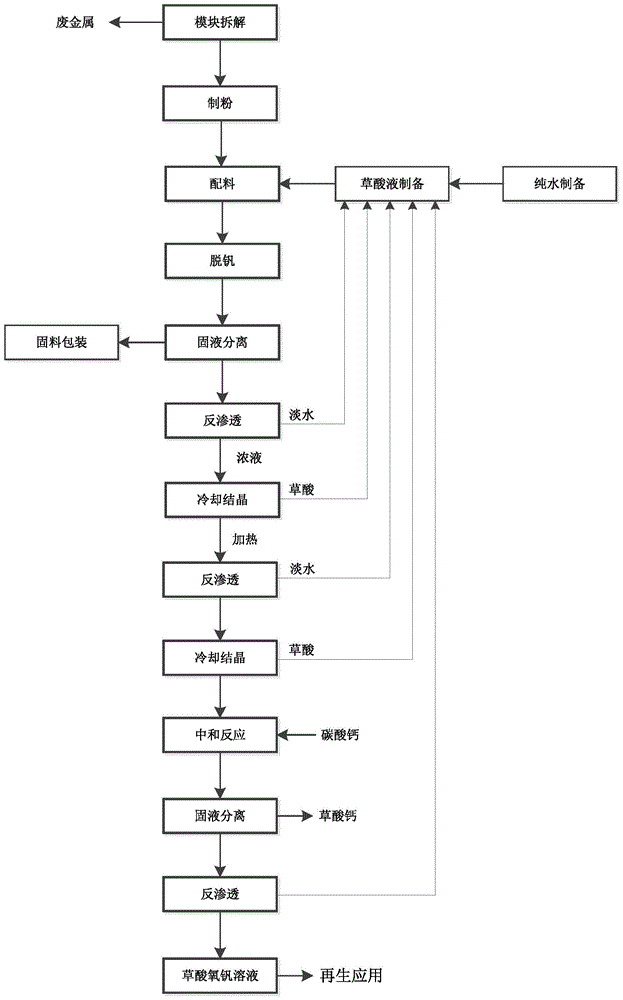

Method used

Image

Examples

Embodiment 1

[0062] Take 1 waste vanadium-tungsten series SCR catalyst monomer, the pitch is 7.6, the longitudinal strength is 230N / cm 2 , the catalyst attaches some ash.

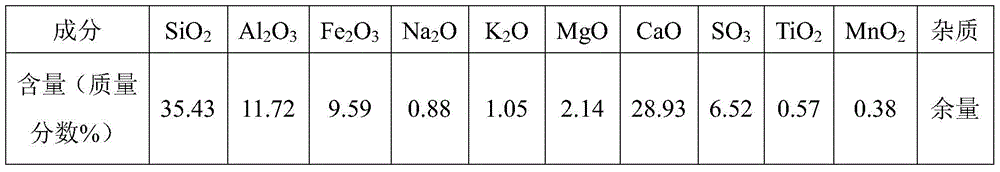

[0063] After testing, the ash composition is as follows:

[0064] Table 3 Example 1 Ash Component Analysis Table

[0065]

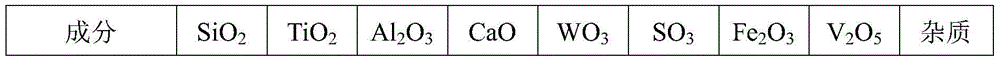

[0066] The catalyst composition is as follows:

[0067] Table 4 Example 1 Catalyst Component Analysis Table

[0068]

[0069] experiment analysis:

[0070] According to the analysis data of catalyst components and ash components, the ash content of the catalyst is characterized by high calcium oxide content. The water pressure of pressure cleaning is 1MPa, a small amount of hydrochloric acid is added to the soaking cleaning solution, and the liquid is circulated using compressed air. After soaking and cleaning, the cleaning solution is rinsed with 0.5MPa water, and the catalyst is dried in a box-type drying oven for 3 hours. The temperature was set at 80°C. The water mass fraction of th...

Embodiment 2

[0090] Take 1 waste vanadium-tungsten series SCR catalyst monomer, the pitch is 8.2, and the longitudinal strength is 260N / cm 2 , the catalyst attaches some ash.

[0091] After testing, the ash composition is as follows:

[0092] Table 5 Example 2 Ash Component Analysis Table

[0093]

[0094] The catalyst composition is as follows:

[0095] Table 6 Example 2 Catalyst Component Analysis Table

[0096]

[0097] experiment analysis:

[0098] According to the analysis data of catalyst components and ash components, the ash content of catalyst attachment is characterized by low calcium oxide content. The water pressure of pressure cleaning is 1.5MPa, add a small amount of hydrofluoric acid into the soaking cleaning solution, and use compressed air to make the liquid circulate. Dry for 3 hours with the temperature set at 90°C. The water mass fraction of the dried catalyst was controlled at 9%.

[0099] From the perspective of catalyst composition, TiO 2 High content, ...

Embodiment 3

[0117] Take 1 waste vanadium-tungsten series SCR catalyst monomer, the pitch is 10.0, the longitudinal strength is 280N / cm 2 , the catalyst attaches some ash.

[0118] After testing, the ash composition is as follows:

[0119] Table 7 Example 3 Ash Component Analysis Table

[0120]

[0121] The catalyst composition is as follows:

[0122] Table 8 Embodiment 3 Catalyst component analysis table

[0123]

[0124] experiment analysis:

[0125] According to the analysis data of catalyst components and ash components, the ash content of catalyst attachment is characterized by low calcium oxide content. The water pressure of pressure cleaning is 2.0MPa, a small amount of hydrofluoric acid is added to the soaking cleaning solution, and the liquid is circulated by using compressed air. Dry for 3 hours with the temperature set at 100°C. The water mass fraction of the dried catalyst was controlled at 9%.

[0126] From the perspective of catalyst composition, TiO 2 High cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com