A sewage treatment device, system and method

A technology of sewage treatment device and sewage treatment system, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of large energy consumption, short backwash cycle, sludge disposal Difficulties and other problems, to achieve the effect of reducing energy consumption, long backwashing cycle, and less sludge discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

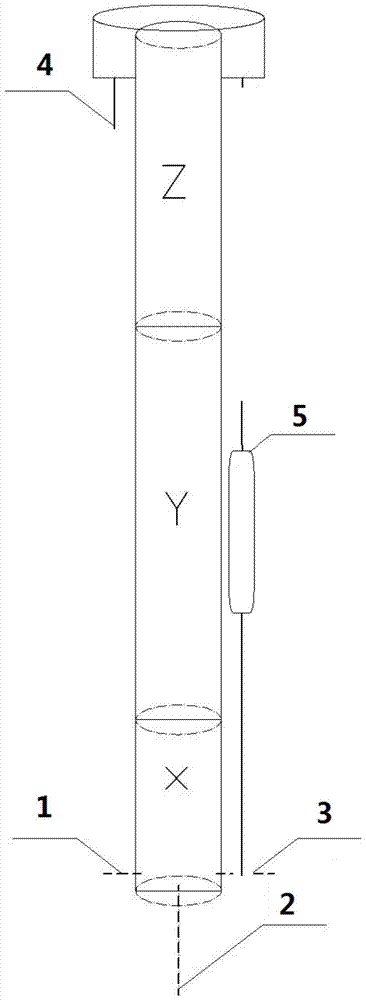

[0028] A sewage treatment plant, such as figure 1 As shown, it includes a reaction column 1, an aerator 2, a water feeder 3, a water outlet 4 and a backwasher 5.

[0029] The reaction column 1 is vertically arranged, a water feeder 3 is arranged below it, an aerator 2 is arranged at the bottom, and a water outlet 4 is arranged above it, the water inlet pipe of the backwasher 5 is connected to the water feeder 3, and the backwasher 5 is connected to the water feeder 3 , The trachea of the flushing device communicates with the air.

[0030] According to the direction of water flow from bottom to top, the reaction column 1 includes an activated sludge water purification area, a biofilm water purification area and a clean water area; the activated sludge water purification area accounts for 25% of the length of the reaction column 1. % to 30%, the biofilm water purification area accounts for 46% to 49% of the length of the reaction column 1, and the rest of the reaction column ...

Embodiment 2

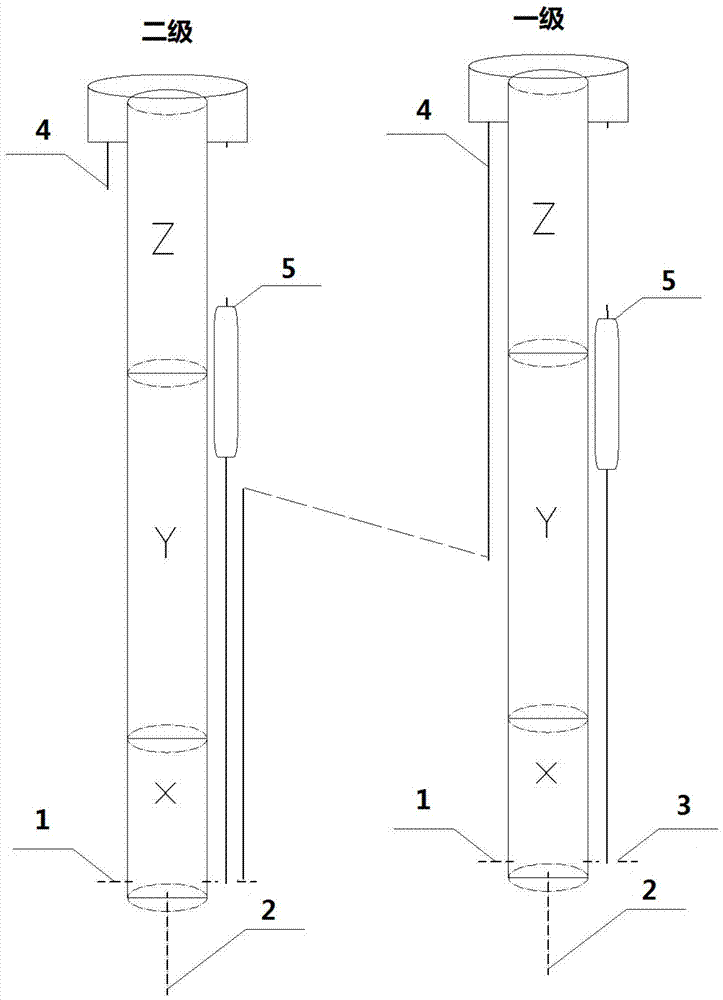

[0038] A sewage treatment system such as figure 2 As shown, there are two sewage treatment devices, namely primary and secondary sewage treatment devices, and the plurality of sewage treatment devices are connected in series. The primary sewage treatment device is a sewage treatment device with aerobic operation, and the secondary sewage treatment device is a sewage treatment device with anoxic operation; the aerator 2 of the primary sewage treatment device is always aerated to realize the reaction The mixing of the water inflow from the column 1 and the sludge from the reaction column 1 and the maintenance of an aerobic environment; the aerator 2 of the secondary sewage treatment device is only aerated when it starts to operate.

[0039] Described primary sewage treatment device, its reaction column 1 height is 1000mm, and the height of activated sludge water purification area is 300mm, and the height of its biofilm water purification area is 460mm, and the height of clear w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com