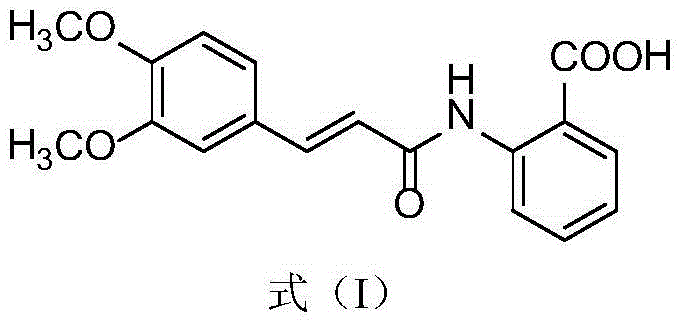

Synthesis method of tranilast

A synthetic method, the technology of special methyl ester, which is applied in the field of chemical synthesis and can solve the problems of high cost and low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

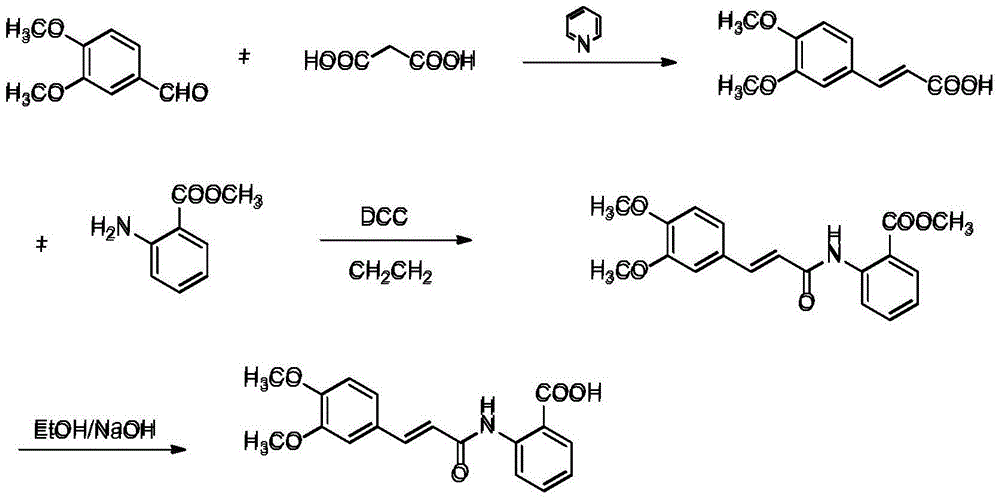

[0032] Tranilast production method of the present invention is as follows:

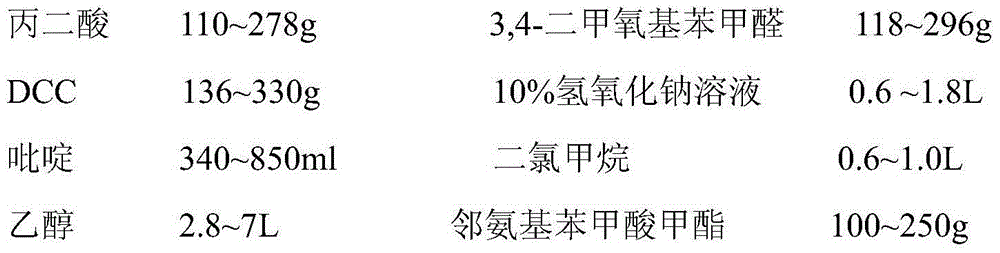

[0033] raw material:

[0034]

[0035] resolve resolution:

[0036] 1. Preparation of 3,4-dimethoxycinnamic acid: Weigh 117g of malonic acid and dissolve it in 200ml of dry pyridine. After stirring evenly, add 125g of 3,4-dimethoxybenzaldehyde and heat up to 90°C , react for 2 to 3 hours, after the reaction, cool slightly, pour the reaction liquid into 500ml of ice water, adjust the pH to 2 to 3 with concentrated hydrochloric acid, a large amount of solid precipitates, let stand, filter with suction, wash the filter cake with ice water until the filtrate The pH was 5-6 and dried to obtain 146 g of solid.

[0037] 2. Preparation of tranilast methyl ester: Weigh 146g of 3,4-dimethoxycinnamic acid and dissolve it in 700ml of dichloromethane, add 158g of DCC under stirring, cool the reaction solution to 0-5°C, and add in batches 105g of methyl anthranilate, stirred and reacted for 1h, reacted at roo...

Embodiment 2

[0040] raw material:

[0041]

[0042] Synthetic method is identical with example 1.

[0043] 1. Preparation of 3,4-dimethoxycinnamic acid: Weigh 234g of malonic acid and dissolve it in 470ml of dry pyridine. After stirring evenly, add 250g of 3,4-dimethoxybenzaldehyde and heat up to 90°C , react for 2 to 3 hours, after the reaction, cool slightly, pour the reaction solution into 800ml ice water, adjust the pH to 2 to 3 with concentrated hydrochloric acid, a large amount of solid precipitates, let stand, filter with suction, wash the filter cake with ice water until the filtrate The pH was 5-6 and dried to obtain 280 g of solid.

[0044] 2. Preparation of tranilast methyl ester: Weigh 280g of 3,4-dimethoxycinnamic acid and dissolve it in 1.4L of dichloromethane, add 305g of DCC under stirring, cool the reaction solution to 0-5°C, batch Add 205g of methyl anthranilate, stir and react for 1h, react at room temperature for 5-6h, filter to remove DCU, remove dichloromethane f...

Embodiment 3

[0047] raw material:

[0048]

[0049] In the synthetic method, the solvent in step 1 is changed to toluene, and the others are the same as in Example 1.

[0050] 1. Preparation of 3,4-dimethoxycinnamic acid: Weigh 150g of malonic acid and 780ml of pyridine and dissolve them in 800ml of dry toluene. After stirring evenly, add 160g of 3,4-dimethoxybenzaldehyde and heat up to 90°C, react for 7-8 hours, after the reaction, cool slightly, pour the reaction solution into 1.5L of ice water, adjust the pH to 2-3 with concentrated hydrochloric acid, a large amount of solid precipitates, let stand, filter with ice, and filter the cake with ice Wash with water until the pH of the filtrate is 5-6, and dry to obtain 150 g of solid.

[0051] 2. Preparation of tranilast methyl ester: Weigh 150g of 3,4-dimethoxycinnamic acid and dissolve in 720ml of dichloromethane, add 163g of DCC under stirring, cool the reaction solution to 0-5°C, and add in batches 109g of methyl anthranilate, stirr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com