A high-safety lithium battery core processing process

A technology with high safety and processing technology, which is applied in the field of high-safety lithium battery core processing technology, can solve the problems of threatening the personal and property safety of users, reducing the conductivity of the electrolyte, increasing the fire and explosion of the battery, and achieving improved Battery safety performance, good heat absorption effect, and the effect of reducing the risk of fire and explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

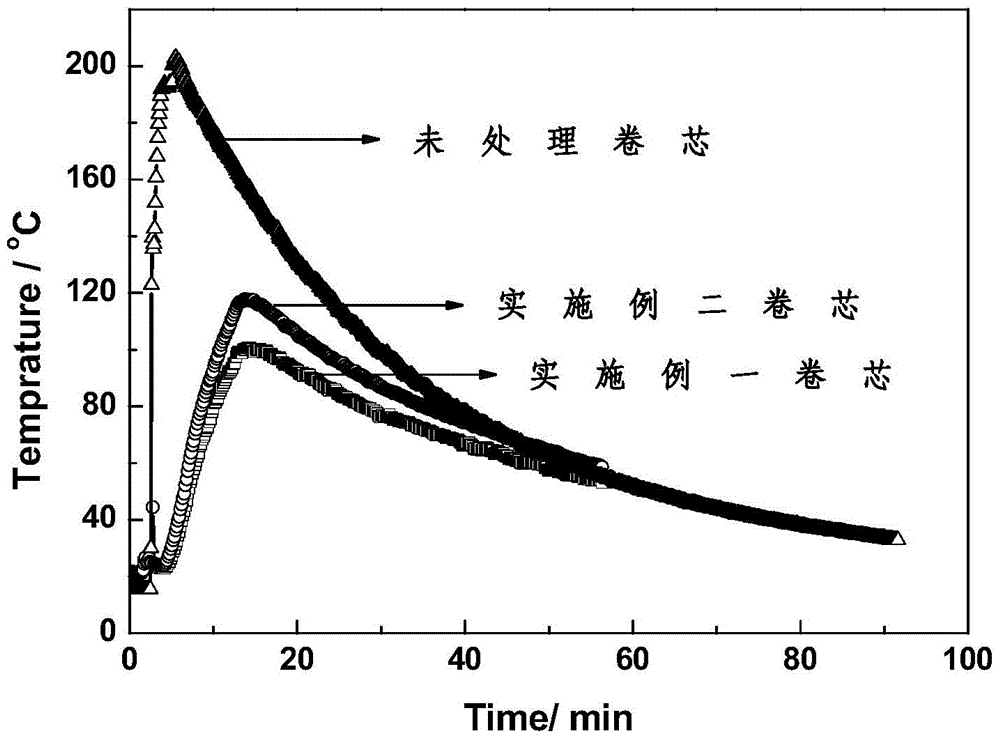

[0024] In order to describe in detail the technical scheme, construction content, achieved objectives and effects, and advantages of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. This embodiment adopts a 1865140 square lithium battery system with a three-roll core structure.

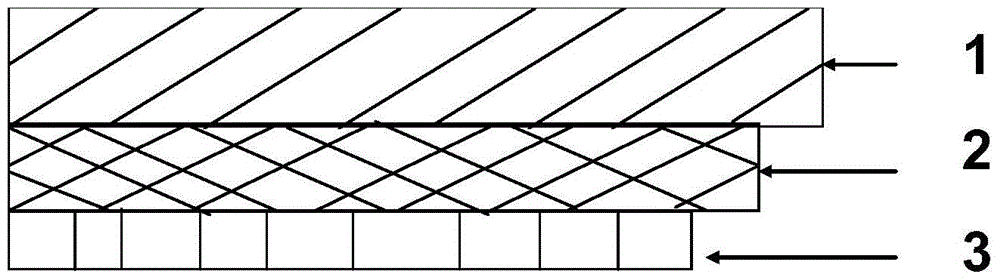

[0025] attached figure 1 It is the implementation example 1 of the present invention, which is a schematic diagram of the film structure prepared for the composite layer. The film adopts a three-layer structure of "substrate-flame-retardant layer-heat-absorbing layer", wherein the substrate is the outer layer, the flame-retardant layer is the middle layer, and the heat-absorbing layer is The layer is the inner layer, and its thickness is 0.3-0.5mm. The treatment of the composite layer film on the core is to wrap the surface of each core.

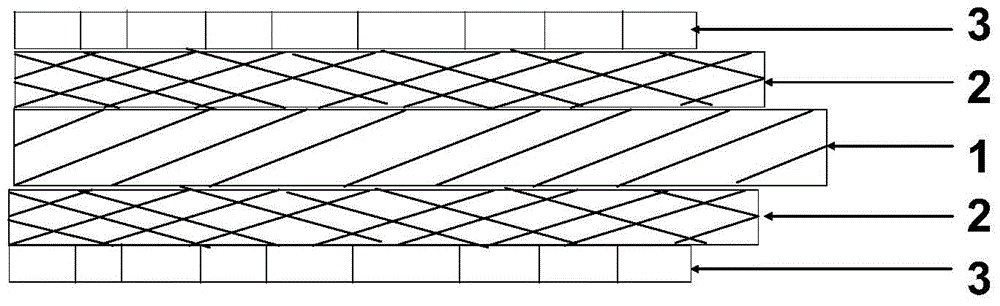

[0026] attached figure 2 It is the second implementation ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com