Production technology of hydrocortisone acetate

A technology of hydrocortisone acetate and hydrocortisone, which is applied in the directions of organic chemistry, steroids, etc., can solve the problems of large amount of catalyst, long reaction time, low yield, etc. Shortened time, good appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

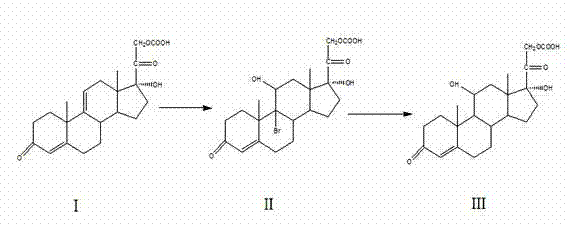

Image

Examples

Embodiment 1

[0021] Add 1kg of hydrocortisone, 0.04kg of barium acetate, and 3L of dimethylformamide into a dry and clean reaction tank replaced with nitrogen three times in advance, stir and dissolve, and heat up to 30°C, then add 0.4 times of hydrocortisone Loose weight of acetic anhydride, heat preservation reaction for 3 hours, nitrogen protection throughout the whole process, keep anhydrous, TLC detection of complete reaction, pour into ice water pre-cooled to 0-10 ℃, stir for 30 minutes, filter and dry to obtain 1.102kg of acetic acid hydrogenation cortisone. The yield is 110.2%, the largest single impurity is 0.30%, and the total impurity is 0.8%.

Embodiment 2

[0023] Add 3kg of hydrocortisone, 0.18kg of barium acetate, and 12L of dimethylformamide into a dry and clean reaction tank replaced with nitrogen three times in advance, stir and dissolve, and heat up to 40°C, then add 0.6 times of hydrocortisone Loose weight of acetic anhydride, heat preservation reaction for 3 hours, nitrogen protection throughout the whole process, keep anhydrous, TLC detection of complete reaction, pour into ice water pre-cooled to 0-10 ℃, stir for 30 minutes, filter and dry to obtain 3.309kg of acetic acid hydrogenation cortisone. The yield is 110.3%, the largest single impurity is 0.29%, and the total impurity is 0.78%.

Embodiment 3

[0025] Add 1kg of hydrocortisone, 0.1kg of barium acetate, and 4L of dimethylformamide into a dry and clean reaction tank replaced with nitrogen three times in advance, stir and dissolve, and heat up to 50°C, then add 1 times of hydrocortisone Loose weight of acetic anhydride, heat preservation reaction for 1 hour, nitrogen protection throughout the whole process, keep anhydrous, TLC detection of complete reaction, pour into ice water pre-cooled to 0-10 ℃, stir for 30 minutes, filter and dry to obtain 1.10kg of acetic acid hydrogenation cortisone. The yield is 110%, the largest single impurity is 0.29%, and the total impurity is 0.70%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com