Modified carbon black particle, color paste, composition, color film substrate and preparation methods thereof, as well as liquid crystal display panel and TFT-LCD display device

A technology of carbon black particles and modified carbon black, which is applied in the treatment of dyed low molecular organic compounds, dyed high molecular organic compounds, pigment slurry, etc. Produces the effect of distinct white lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

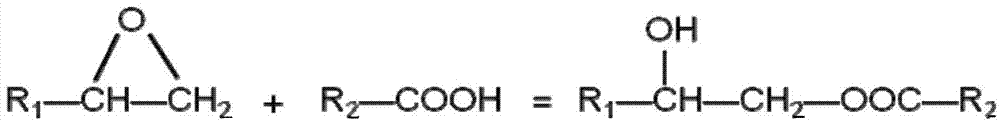

[0039] According to the preparation method of modified carbon black particles of the present invention, the method provides raw materials in parts by mass: 5-20 parts of carbon black particles, 5-40 parts of resin, 0.1-5 parts of catalyst and 30-85 parts of solvent; and The method includes a coating step: adding carbon black particles and resin into a solvent, stirring and raising the temperature to 60-110 DEG C, adding a catalyst, and reacting for 1-5 hours to obtain a modified carbon black particle solution.

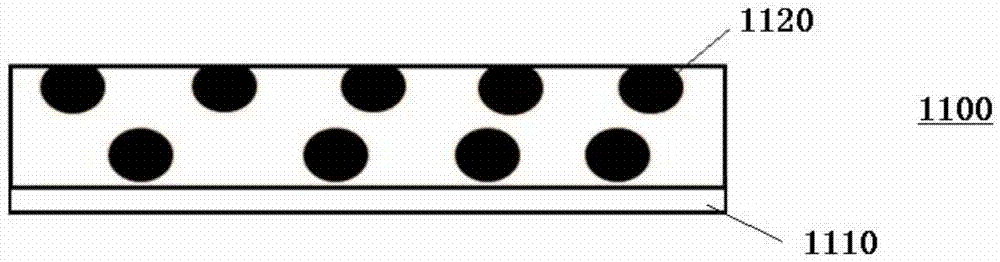

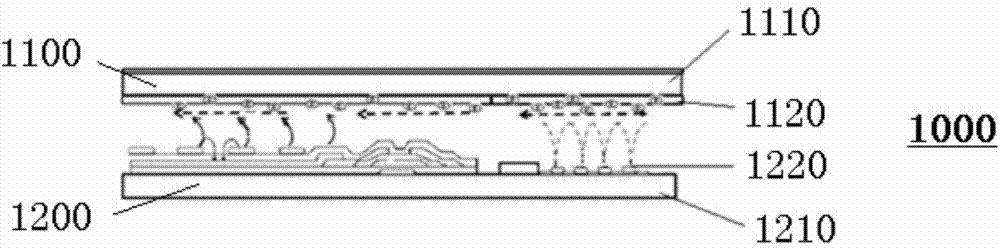

[0040] according to image 3 It can be seen that a large number of polar carboxyl groups and hydroxyl groups are distributed on the surface of carbon black particles. Although carbon black particles themselves have high optical density, due to the existence of polar groups on their surface, the conductivity is enhanced and the impedance performance is reduced. Carbon black particles 1121 The black matrix 1120 on the color filter substrate 1100 prepared as a raw materia...

Embodiment approach

[0043] According to one embodiment of the method for preparing modified carbon black particles of the present invention, the catalyst is preferably: organotin compounds, tertiary amine compounds and p-toluenesulfonic acid; wherein the organotin compounds are further preferably dibutyltin dilaurate or stannous octoate ; The tertiary amine compound is preferably one of the following: triethylamine, triethanolamine and triethyleneamine.

[0044] According to the preparation method of the present invention, the method further includes a post-processing step: under stirring at 1000-25000 rpm, 5-20 parts by mass of the modified carbon black particle solution is added dropwise to 80-95 parts by mass In the ethanol solution, stir until the carbon black particles are completely dispersed, then filter, and sieve and dry the obtained filter cake to obtain modified carbon black particles.

[0045] According to the preparation method of the present invention, the modified carbon black part...

Embodiment 1

[0071] According to the preparation method of modified carbon black particles of the present invention, the method provides raw materials in parts by mass: 5 parts of carbon black particles, 5 parts of resin, 0.1 part of catalyst and 30 parts of solvent; and the method includes a coating step: Add the carbon black particles and resin into the solvent, stir and raise the temperature to 60°C, add the catalyst, and react for 1 hour to obtain the modified carbon black particle solution. The method further includes a post-processing step: under stirring at 1000rpm, 5 parts by mass parts of the modified carbon black particle solution is added dropwise to 80 parts by mass part of the ethanol solution, and the mixture is stirred until the carbon black particles are completely dispersed. filtering, sieving and drying the obtained filter cake to obtain modified carbon black particles, and the resin is epoxy resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com