Penicillium ochrochloron and its application in preparation of brefeldin A

A technology of Penicillium ochracea and a preservation number is applied to Penicillium ochracea and its application field in the preparation of brefeldin A, which can solve the problems of many by-products, low fermentation level, easy degradation of bacterial species, etc., and achieves great application value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

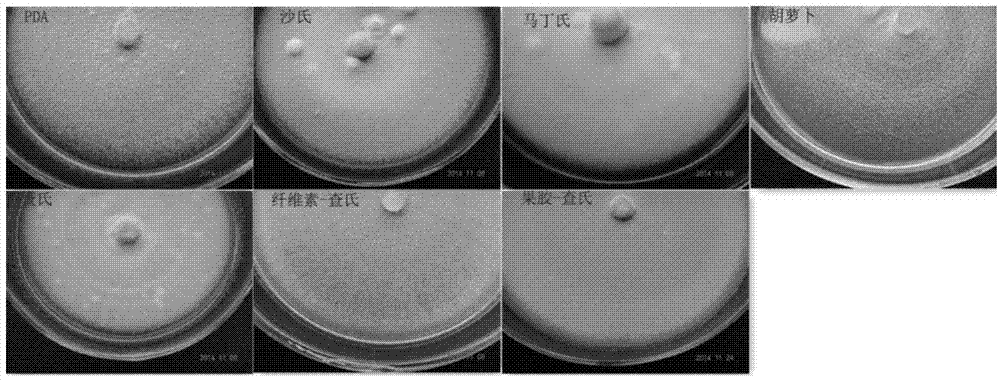

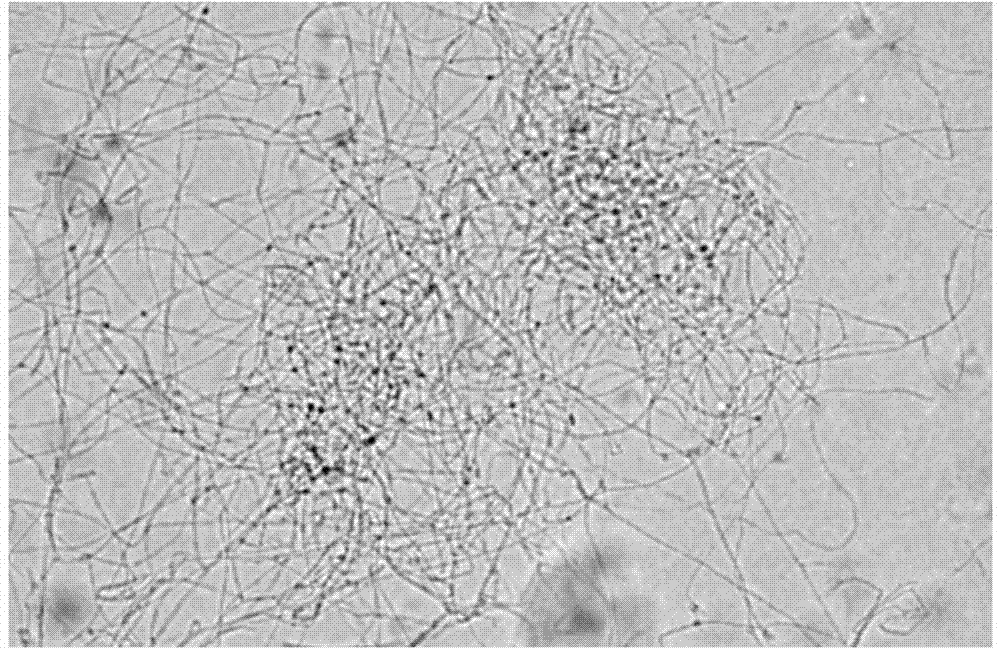

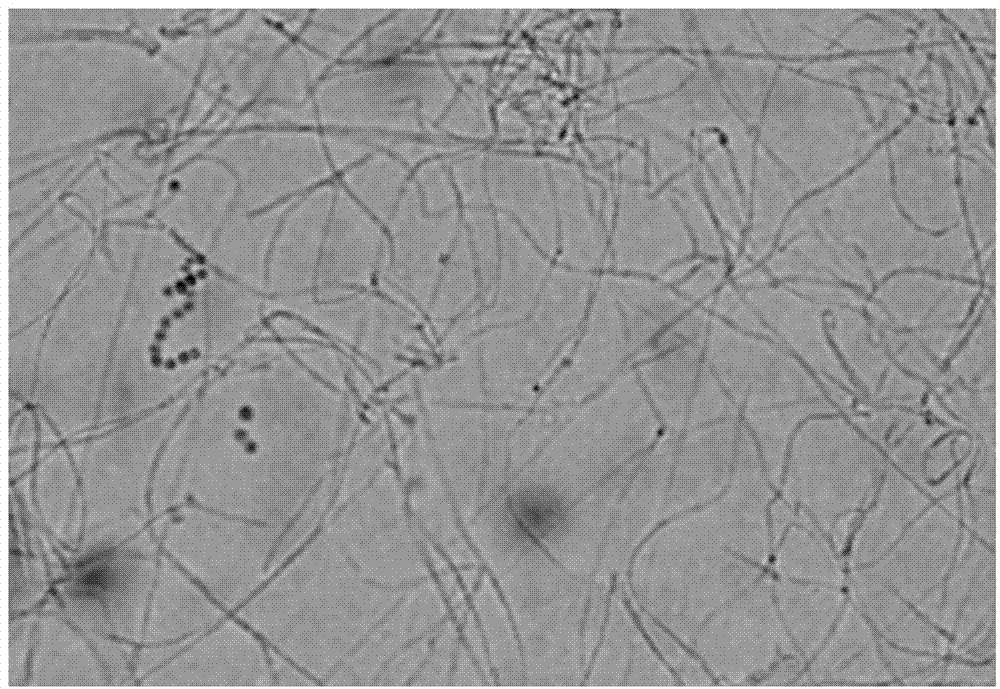

[0030] The isolation of embodiment 1 bacterial strain

[0031] (1) Strain screening: the collected plant samples were surface-sterilized and cut into small pieces of 0.5 cm in length, and inoculated into the center of a PDA plate containing 60 μg / mL streptomycin and 100 μg / mL ampicillin. Cultivate at 28°C for 2 to 15 days, transfer a single strain to fresh PDA medium in time by using the tip mycelia picking method, and then repeat the separation of mycelia until it is a pure culture, number the obtained purified strains, and Transferred to fermentation medium (medium composition: potato 200g / L, glucose 20g / L), 28°C, 150rpm shaking culture for 15 days. The fermentation broth was centrifuged, the supernatant was collected, and extracted 3 times with 100 mL ethyl acetate, the extract phase was collected, the ethyl acetate was recovered by distillation under reduced pressure, the obtained crude extract was dissolved in methanol, and thin layer chromatography (Thin Layer Chromatogr...

Embodiment 2

[0043] Example 2 Effect of Different C Sources on the Preparation of BFA by Fermentation of Penicillium ochregreen SWUKD4.211

[0044] In order to investigate the influence of different C sources on the fermentation level of BFA in the medium, five different fermentation mediums were designed. The composition is respectively:

[0045] Medium A: potato 200.0g / L, xylose 20.0g / L, ammonium sulfate 2.0g / L, potassium dihydrogen phosphate 1.0g / L, magnesium sulfate heptahydrate 2.0g / L, calcium carbonate 5.0g / L, solvent For distilled water, pH=6;

[0046] Medium B: potato 200.0g / L, glucose 20.0g / L, ammonium sulfate 2.0g / L, potassium dihydrogen phosphate 1.0g / L, magnesium sulfate heptahydrate 2.0g / L, calcium carbonate 5.0g / L, the solvent is distilled water, pH=6;

[0047] Medium C: potato 200.0g / L, sucrose 20.0g / L, ammonium sulfate 2.0g / L, potassium dihydrogen phosphate 1.0g / L, magnesium sulfate heptahydrate 2.0g / L, calcium carbonate 5.0g / L, the solvent is distilled water, pH=6;

...

Embodiment 3

[0052] Example 3 Effects of Different Rotating Speeds on the Preparation of BFA by Fermentation of Penicillium ochregreen SWUKD4.211

[0053] In order to investigate the influence of rotating speed on the fermentation level of BFA, three different shaking table rotating speeds were designed, and the bottling volume of the fermentation medium was 100mL / 250mL triangular flask (containing 2 glass beads with a diameter of 4mm), and the composition of the fermentation medium was For: potato 200.0g / L, glucose 20.0g / L, ammonium sulfate 2.0g / L, potassium dihydrogen phosphate 1.0g / L, magnesium sulfate heptahydrate 2.0g / L, calcium carbonate 5.0g / L, solvent is distilled water, pH=6, sterilized at 121°C for 20 minutes.

[0054]The bottling volume of the fermentation medium is 100mL / 250mL Erlenmeyer flask. Under sterile conditions, use a puncher (6mm in diameter) to take a certain amount of activated strains and transfer them to the fermentation medium. , 170rpm shaker for 7 days. After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com