Preparation method of high-activity microencapsulated lactic acid bacteria starter

A technology of fermentation and microencapsulation of lactic acid bacteria, which is applied in the direction of being fixed on/in an organic carrier, can solve the problems of reduced vitality of high-density bacteria, damage of strains, poor heat resistance, etc., to maintain high-efficiency vitality and avoid pollution. , the effect of reducing the impact of the external environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solution of the present invention will be further described through specific embodiments.

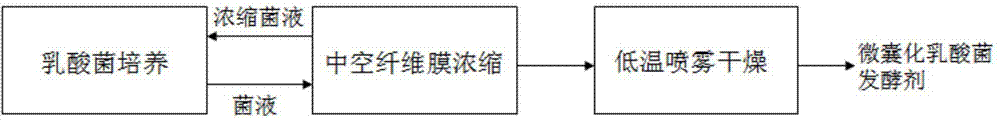

[0035] Such as figure 1 Shown, a kind of preparation method of high vigor microencapsulated lactic acid bacteria starter comprises the following steps:

[0036] (1) The medium is: soybean peptone 10g / L, beef extract 10g / L, yeast extract 5g / L, diammonium citrate 2g / L, sodium acetate 5g / L, magnesium sulfate 0.58g / L, copper sulfate 0.25 g / L, Tween 801mL / L, maltose 20g / L, buffer system 0.05mol / L K 2 HPO 4 -KH 2 PO 4 (pH6.2~6.4);

[0037] Put the medium into the bioreactor, inoculate 1% (v / v) Lactobacillus sakei subsp. Sakei (commercially available) on the medium for cultivation, the cultivation temperature is 37°C, pH6.2~ 6.4, Cultivate until the number of unit colonies is 10 7 More than cfu / mL;

[0038] (2), cleaning and sterilizing the PVDF hollow fiber membrane of the hollow fiber concentration device, the steps of cleaning and sterilization are:

[0039] (a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com