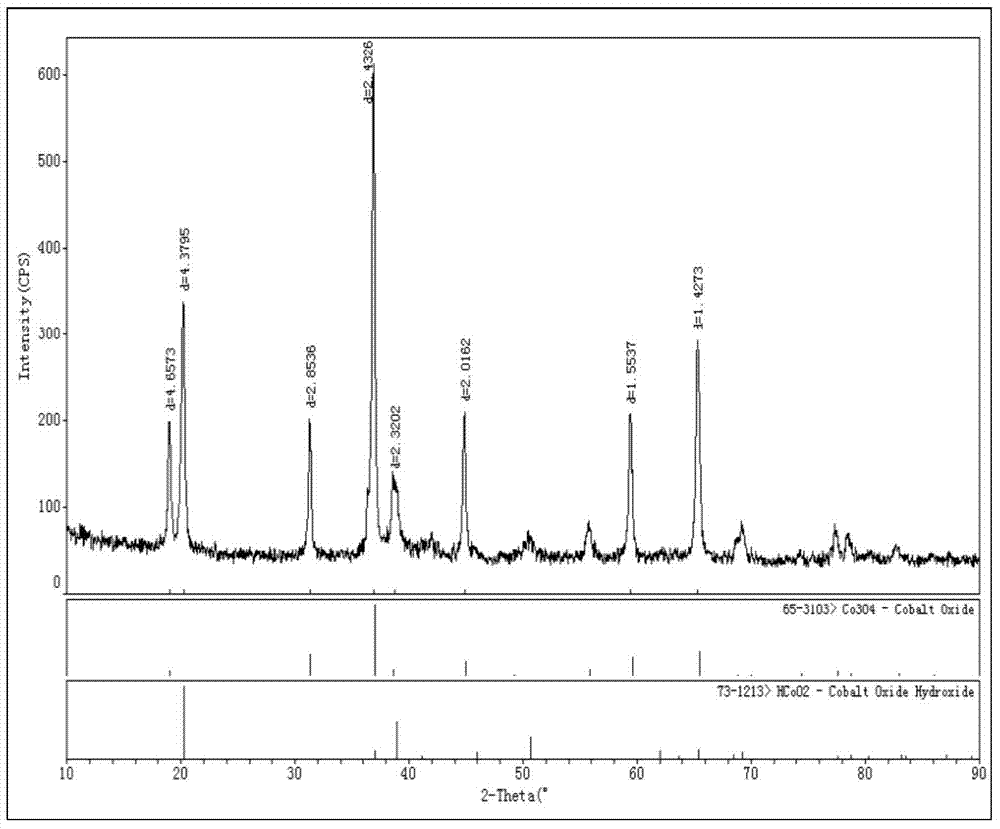

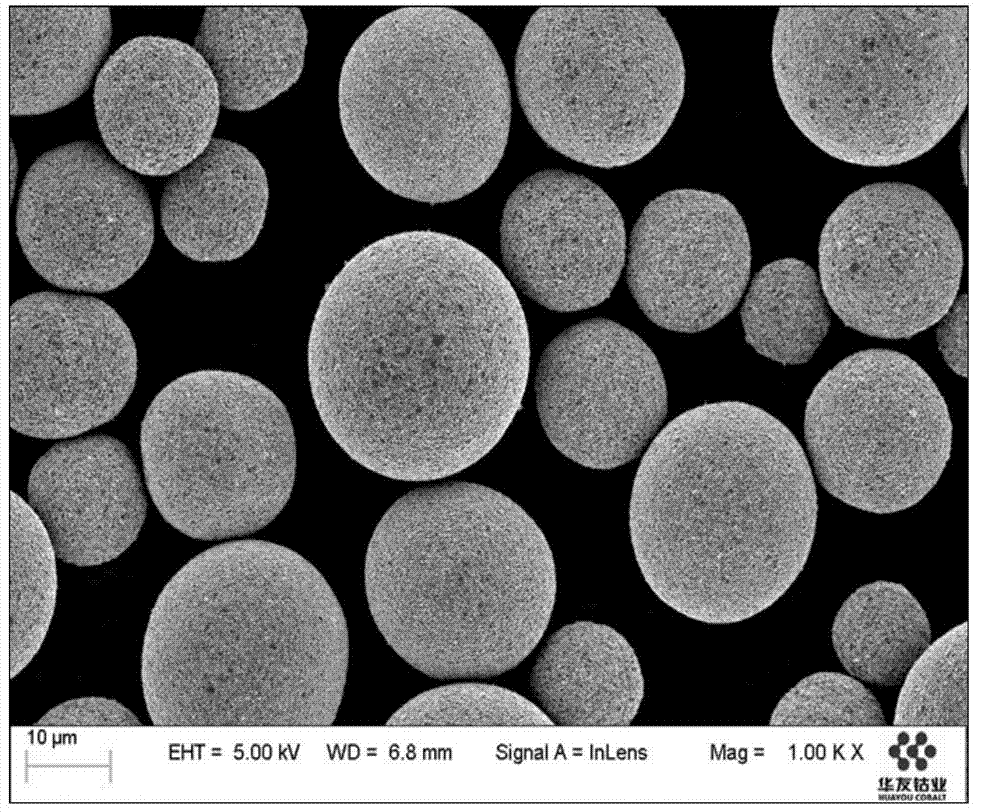

Preparation method of spherical hydroxyl cobaltous oxide-cobaltosic oxide composite material

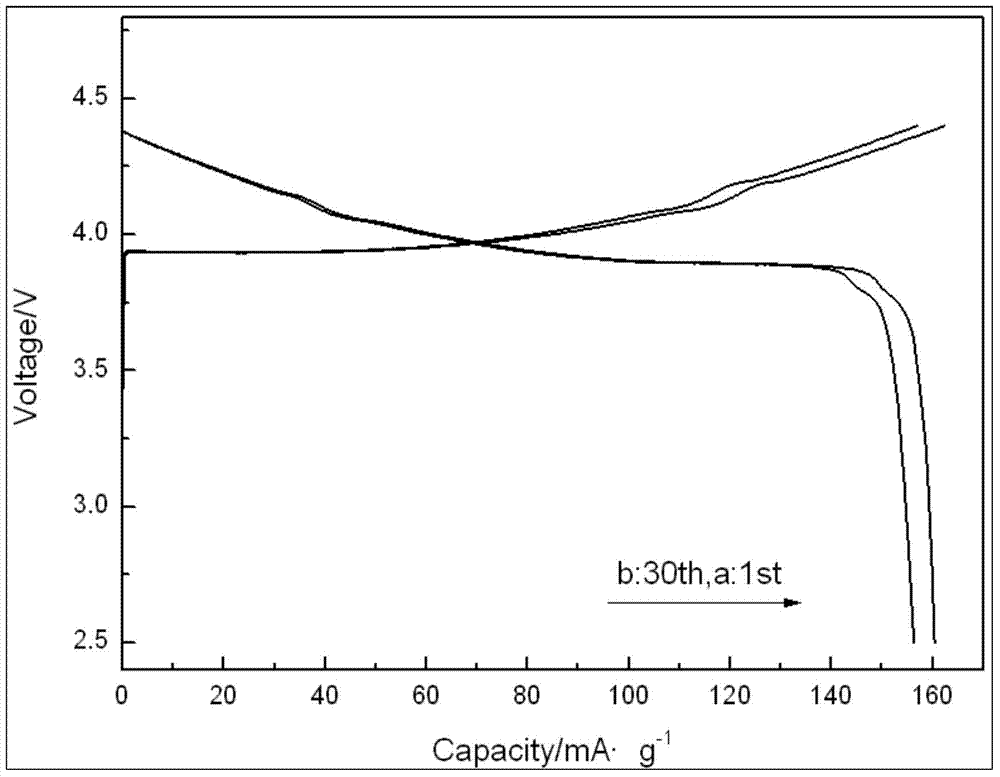

A technology of cobalt oxyhydroxide and tricobalt tetroxide, which is applied in electrical components, battery electrodes, circuits, etc., can solve the problems of high cut-off voltage, strong structural stability, low vibration, etc., and achieves low cost, simple preparation process, and good electricity. Effects of chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The production steps are as follows:

[0025] 1. Raw material preparation

[0026] Add an appropriate amount of 10.0mol / L NaOH solution into the lye preparation tank, add a corresponding amount of pure water into the tank according to the final concentration of 5.0mol / L, use a circulating pump to make the concentration of lye in the tank uniform, and check the concentration of lye After the range of 5.0±0.1mol / L, put the lye into the lye feeding tank.

[0027] Add an appropriate amount of CoSO to the cobalt liquid preparation tank 4 Solution, after detecting the concentration of metal Co, add a corresponding amount of pure water to the tank according to the final Co concentration of 1.7mol / L, and circulate to make the concentration uniform. The cobalt liquid (ie cobalt salt solution) is poured into the cobalt liquid transfer tank. In the cobalt liquid transfer tank, add complexing agent and auxiliary agent, the concentration is (1kg auxiliary agent+4kgEDTA-2Na) / m 3 ...

Embodiment 2

[0037] The production steps of this example are basically the same as in Example 1, only the following indicators are different: the cobalt liquid flow rate is 210±2L / h, the stirring is controlled at 210±1rpm, and the air flow rate is 20m 3 / h, the concentration of adding complexing agent and auxiliary agent is (2kg auxiliary agent+10kgEDTA-2Na) / m 3 (The mass ratio of triethanolamine to ascorbic acid in the auxiliary agent is 0.2:1). After synthesis, cyclone classification, pressure filtration, washing and drying, the sample was obtained, with a D50 of 15.3 μm and a tap density of 2.79 g / cm 3 , a large-sized spherical cobalt oxyhydroxide-cobalt tetroxide composite sample with a cobalt content of 69.1%.

Embodiment 3

[0039] The production steps of this example are basically the same as in Example 1, only the following indicators are different: the cobalt liquid flow rate is 100±1L / h, the stirring is controlled at 170±1rpm, and the air flow rate is 12m 3 / h, the concentration of adding complexing agent and auxiliary agent is (0.5kg auxiliary agent+4kgEDTA-2Na) / m 3 (The mass ratio of triethanolamine to ascorbic acid in the auxiliary agent is 0.8:1). After synthesis, cyclone classification, pressure filtration, washing and drying, the sample was obtained, with a D50 of 21.8 μm and a tap density of 2.93 g / cm 3 , a large-sized spherical cobalt oxyhydroxide-cobalt tetroxide composite sample with a cobalt content of 68.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com