A kind of nano-titanium dioxide/chitosan three-dimensional porous composite material and its preparation method

A nano-titanium dioxide and composite material technology is applied in the field of nano-titanium dioxide/chitosan three-dimensional porous composite materials and their preparation, and can solve the problems of lack of three-dimensional interconnected macroporous structure, difficult control of nanocrystalline size, high adsorption performance, etc. Easy to use widely, good mechanical properties, high porosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

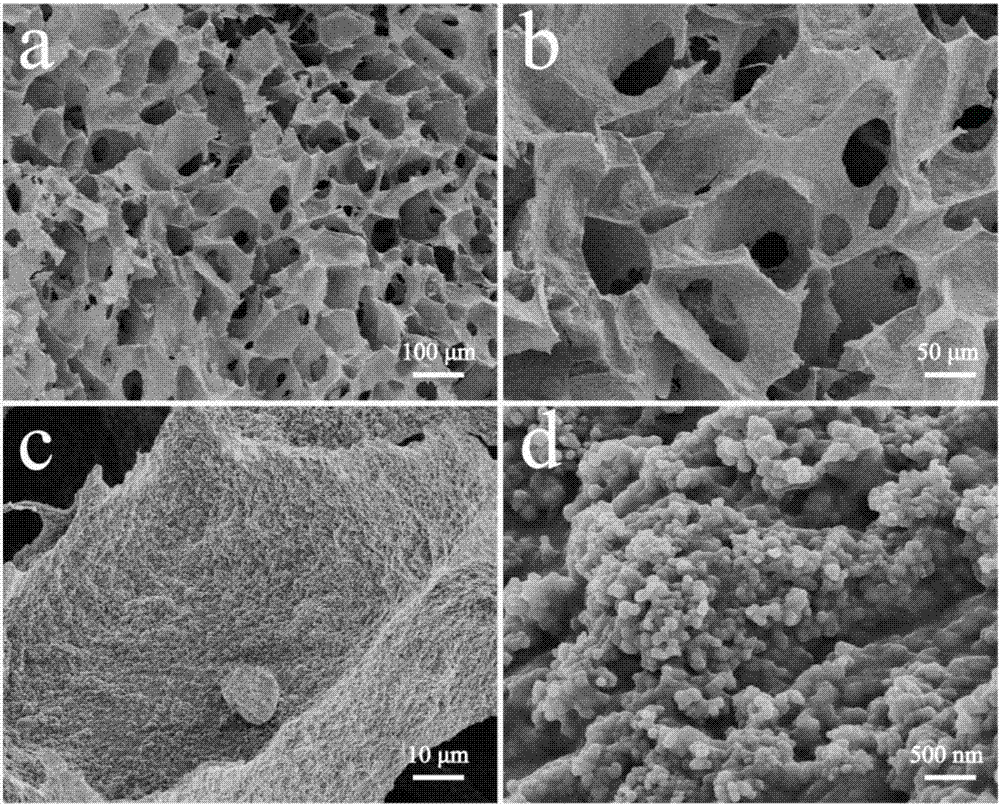

[0029] (1) Accurately weigh 10.00 g of chitosan and place it in 250 mL of acetic acid solution with a volume fraction of 2%, stir until the chitosan is completely dissolved in the acetic acid solution, and ultrasonically remove air bubbles. Then accurately weigh 10.00 g of nano-titanium dioxide powder (with a particle size of 10-30 nm) and place it in 20.00 mL of chitosan solution, stir until the nano-titanium dioxide and chitosan solution are evenly mixed, and ultrasonically remove air bubbles.

[0030] (2) Transfer the nano-titanium dioxide / chitosan mixed slurry prepared in (1) to a 12mm×18mm (diameter×height) mold, and transfer it to a freeze dryer, under the conditions of -80°C and 1~2Pa Freeze-dry for 48 hours to obtain nano-titanium dioxide / chitosan material.

[0031] (3) Soak the nano-titanium dioxide / chitosan material prepared in step (2) in 1mol / L sodium hydroxide solution for 1h-24h, wash with deionized water until neutral, and obtain nano-titanium dioxide / chitosan t...

Embodiment 2

[0036] (1) Accurately weigh 10.00 g of chitosan and place it in 250 mL of acetic acid solution with a volume fraction of 2%, stir until the chitosan is completely dissolved in the acetic acid solution, and ultrasonically remove air bubbles. Then accurately weigh 10.00 g of nano-titanium dioxide powder (with a particle size of 20-50 nm) and place it in 10.00 mL of chitosan solution, stir until the nano-titanium dioxide and chitosan solution are evenly mixed, and ultrasonically remove air bubbles.

[0037] (2), (3) method is the same as embodiment 1, promptly gets nano-titanium dioxide / chitosan three-dimensional porous composite material, and porosity is 80%, and aperture is 50-250nm, and specific surface area is 107.49m 2 / g.

Embodiment 3

[0039] (1) Accurately weigh 10.00 g of chitosan and place it in 250 mL of acetic acid solution with a volume fraction of 2%, stir until the chitosan is completely dissolved in the acetic acid solution, and ultrasonically remove air bubbles. Then accurately weigh 20.00 g of nano-titanium dioxide powder (with a particle size of 10-30 nm) and place it in 10.00 mL of chitosan solution, stir until the nano-titanium dioxide and chitosan solution are uniformly mixed, and ultrasonically remove air bubbles.

[0040] (2), (3) method is the same as embodiment 1, obtains nano-titanium dioxide / chitosan three-dimensional porous composite material, and porosity is 80%, and aperture is 50~200nm, and specific surface area is 104.64m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com