Dual-tower serially connected rectifying, separating and purifying process of hydrocyanic acid

A technology of rectifying separation and hydrocyanic acid, which is applied in the directions of cyanic acid/isocyanic acid, cyanide, inorganic chemistry, etc., can solve the problems of easy polymerization of hydrocyanic acid, harm of rectification equipment, etc. The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

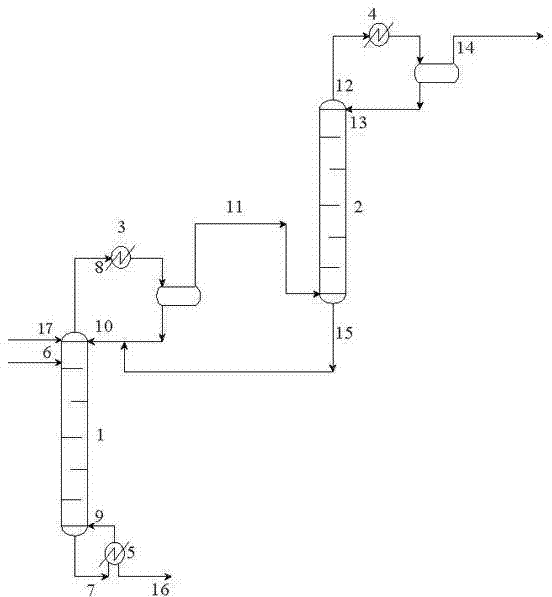

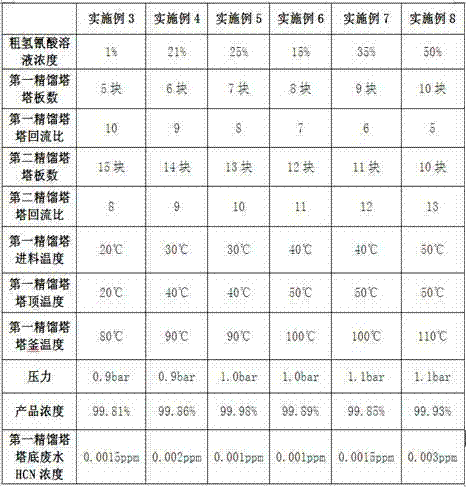

[0026] Example 1 Two-tower series rectification system for separation and purification of hydrocyanic acid

[0027] Mainly comprising the first rectification tower 1 and the second rectification tower 2, the first rectification tower and the second rectification tower are packing rectification towers, the first rectification tower top is provided with a condenser 3, and the bottom of the tower is provided with a further A boiler 5 and a condenser 4 are arranged at the top of the second rectifying column, and the condensers are all partially condensed.

[0028] The crude prussic acid solution is fed into the feed port 6 at the second tray place of the first rectifying tower, and the feed liquid at the outlet port 7 of the first rectifying tower still enters the reboiler 5, and after being vaporized into a gas phase, passes through The tower bottom reflux 9 of the first rectifying tower enters the tower body, and the gaseous phase component of the first rectifying tower towe...

Embodiment 2

[0030] A double-tower series rectification separation and purification process for prussic acid, comprising the following steps:

[0031] (1) Feed

[0032] The concentration of the crude hydrocyanic acid solution is 1%-50%, preheated to a certain temperature, and fed to the second tray of the first rectification tower.

[0033] (2) Rectification and partial condensation in the first distillation column

[0034] Set the temperature at the top of the first rectification tower, the temperature of the bottom of the tower, and the pressure inside the tower. The steam at the top of the tower enters the condenser to condense. Feed at one tray.

[0035] (3) Add polymerization inhibitor

[0036] A polymerization inhibitor feeding port 17 is arranged at the top of the first rectification tower, where the polymerization inhibitor is precisely metered into the hydrogen cyanide easy-to-polymerize region, and the polymerization inhibitor is acetic acid.

[0037] (4) Distillation in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com