Melamine modified polyamino cyclotriphosphazene and preparation method thereof

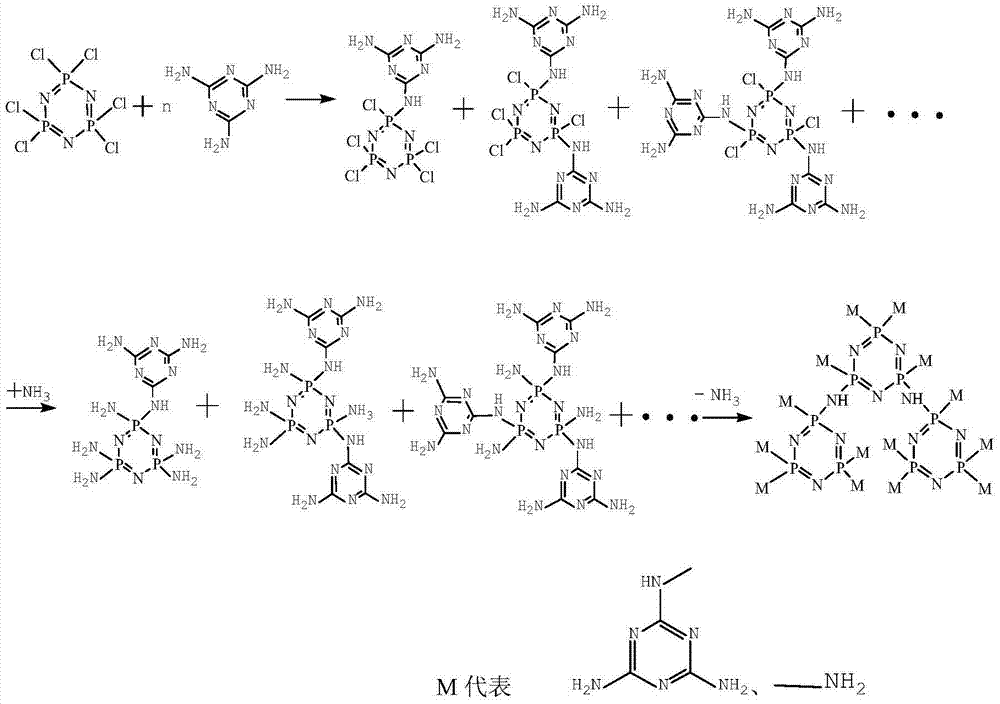

A technology of polyaminocyclotriphosphazene and melamine, which is applied in the field of melamine-modified polyaminocyclotriphosphazene and its preparation, can solve the problems of poor thermal stability, high water solubility, limitations, etc., and achieve improved thermal stability and water-soluble The effect of reducing property and hygroscopicity and improving phosphorus yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation technology of melamine modified polyaminocyclotriphosphazene comprises the steps:

[0029] (1) Condensation: Add 10g of hexachlorocyclotriphosphazene, 3.6g of melamine, 60g of chlorobenzene and 8.5g of triethylamine into a 250mL three-necked flask, and heat the material to 80-85°C in a water bath under nitrogen protection and stirring. After maintaining the temperature for 18 hours, cool down to room temperature, sample and analyze the free chlorine content, and calculate the degree of substitution of chlorine in the hexachlorocyclotriphosphazene according to the free chlorine content (the percentage of free chlorine mass and total chlorine mass in the sample). The free chlorine content is analyzed by the mercury method, and the specific steps refer to GB / T3051-2000. After analysis, the substitution degree of chlorine was 43.3%.

[0030] (2) Ammonification: The above materials are further cooled to about 0°C with an ice-salt bath, and ammonia gas is intro...

Embodiment 2

[0034] The preparation technology of melamine modified polyaminocyclotriphosphazene comprises the steps:

[0035] (1) Condensation: Add 10g of hexachlorocyclotriphosphazene, 5.4g of melamine, 60g of chlorobenzene and 13.0g of triethylamine into a 250mL three-necked flask, and heat the material to 80-85°C in a water bath under nitrogen protection and stirring. And maintain the temperature for 18h and then cool down to room temperature. After analysis, the substitution degree of chlorine was 54.0%.

[0036] (2) Ammonification: The above materials are further cooled to about 0°C with an ice-salt bath, and ammonia gas is introduced at a constant speed under stirring for 18 hours, and a total of about 10 g of ammonia gas is introduced, and then filtered, and the filter cake is dried to obtain a white powder Solid 30.2g—melamine-modified aminocyclotriphosphazene and the mixture of by-product water-soluble ammonium salts (triethylamine hydrochloride and ammonium chloride). After an...

Embodiment 3

[0040] The preparation technology of melamine modified polyaminocyclotriphosphazene comprises the steps:

[0041] (1) Condensation: Add 10g of hexachlorocyclotriphosphazene, 7.2g of melamine, 60g of chlorobenzene and 17.4g of triethylamine into a 250mL three-necked flask, and heat the material to 80-85°C in a water bath under nitrogen protection and stirring. And maintain the temperature for 18h and then cool down to room temperature. After analysis, the substitution degree of chlorine was 64.4%.

[0042] (2) Ammonification: The above materials are further cooled to about 0°C with an ice-salt bath, and ammonia gas is introduced at a constant speed under stirring for 18 hours, and a total of about 10 g of ammonia gas is introduced, and then filtered, and the filter cake is dried to obtain a white powder 35.8 g of solids—a mixture of melamine-modified aminocyclotriphosphazene and ammonium salts. After analysis, the substitution degree of chlorine was 99.1%.

[0043] (3) Polyc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com