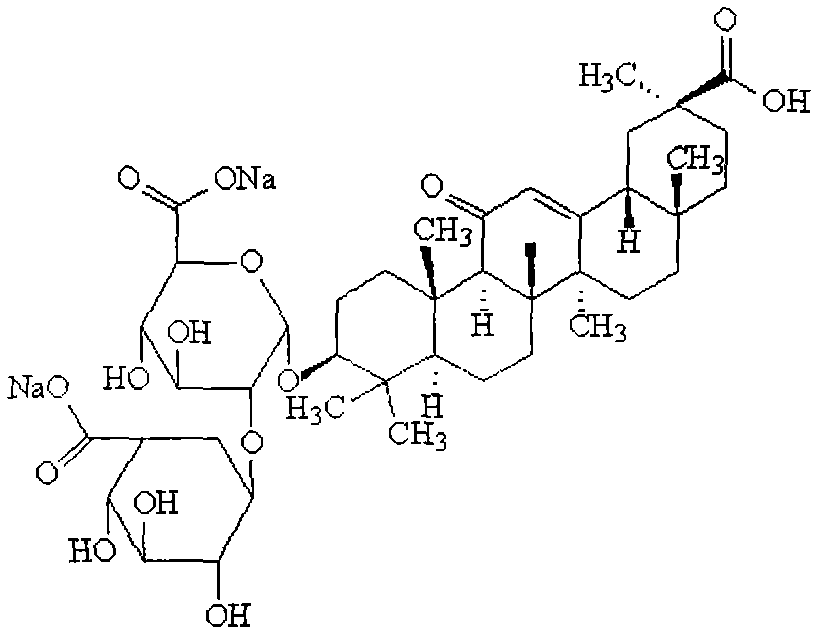

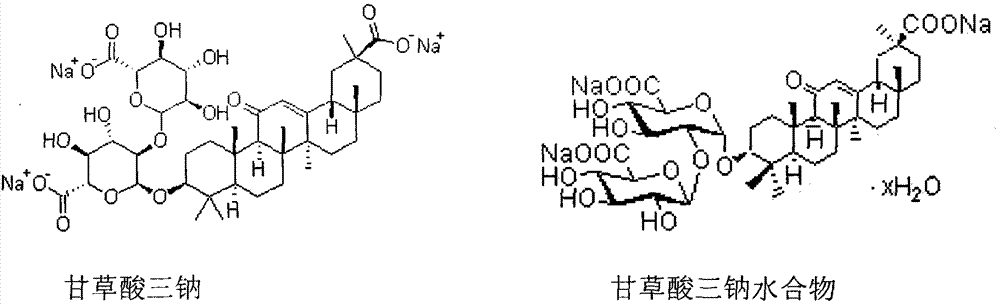

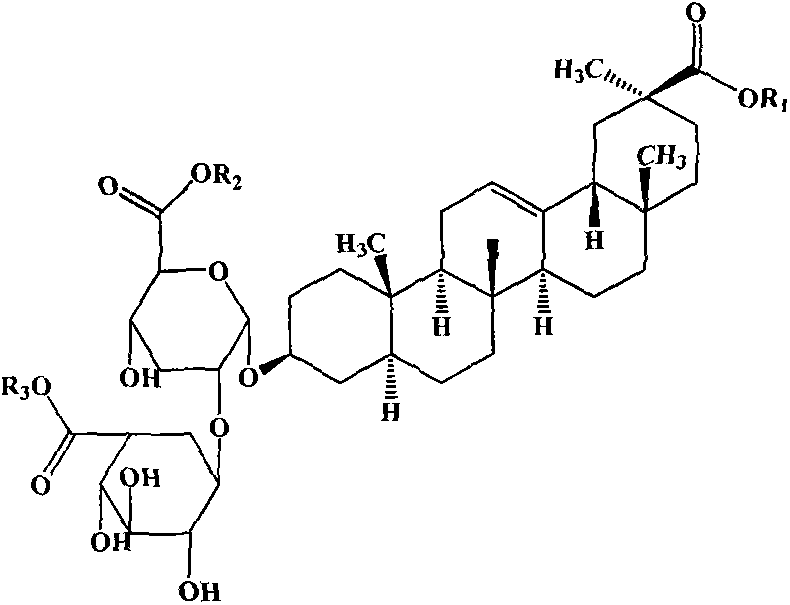

Preparation method of sodium glycyrrhizinate and hydrates thereof

A technology of glycyrrhizic acid sodium salt and glycyrrhizic acid trisodium salt, which is applied in the direction of preparation of sugar derivatives, steroids, chemical instruments and methods, and can solve the problems of high cost, large investment in ultrafiltration, and small production volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Refining of glycyrrhizic acid: adding 100g of crude glycyrrhizic acid with a content of 75% to 300mL of n-butanol, extracting under reflux for 2.0h, pouring out the extract, and extracting the residue with 200mL of n-butanol under reflux for 1.5h, pouring out the extract, and refluxing the residue Extract with 100mL n-butanol under reflux for 1.0h. Combine 3 extracts, add 3-5% (W / V) 3-5% (W / W) activated clay and 3-5% (W / W) diatomaceous earth, incubate under reflux for 30min, filter, The filtrate was concentrated under reduced pressure to a specific gravity of 1.15-1.20, a small amount of ether was added, fully stirred, left to stand, crystallized, centrifuged, and the crystallized product was vacuum-dried at 60-70°C for 4-6 hours to obtain 71g of refined glycyrrhizic acid with a content of 99.5%.

[0018] Preparation of disodium glycyrrhizic acid: Dissolve 80g of glycyrrhizic acid with 320mL of n-butanol, add sodium carbonate to adjust the pH to 6-7, heat under reflux f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com