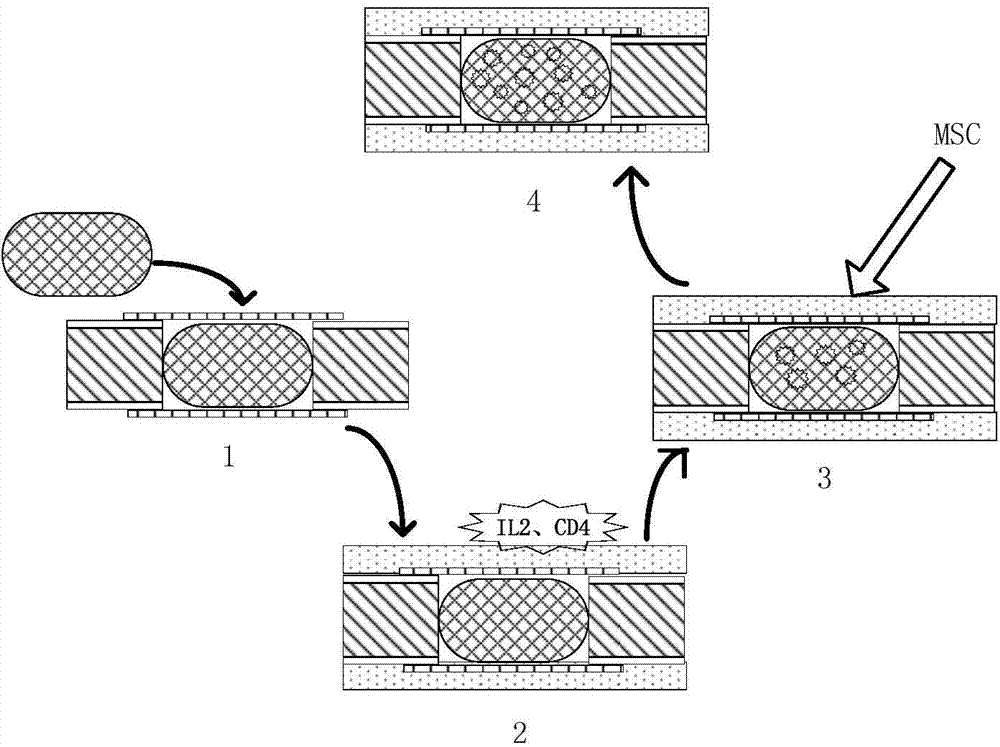

Step-by-step tissue engineering bone building method

A tissue engineering bone and construction method technology, applied in the field of bone tissue engineering, can solve the problems of slow ingrowth of microvessels, insufficient blood vessel growth rate, difference in cell growth ability, etc., and achieve the effect of maximizing the survival rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. Establishment of animal models

[0025] Since the rabbit radius model has been widely reported in various literatures as an orthotopic bone defect model, it is reported that a 1.5cm defect is a critical defect, and the animal cost is relatively economical. Therefore, an adult male white rabbit, 5 months old, with a radius defect of 1.5 cm was selected as the experimental animal model.

[0026] 2. Experimental grouping

[0027] Postplantation group: see below for specific experimental procedures;

[0028] Blank control group: without any treatment at the initial stage, only on the 14th day, 0.3ml of PBS was injected (no prevascularized seed cells were implanted, nor were osteoblast seed cells implanted);

[0029] Control group 1: traditional tissue engineering method, that is, 6 million bone marrow mesenchymal stem cells after osteogenesis induction were implanted at the initial stage;

[0030] Control group 2: no prevascularized seed cells were implanted at the in...

Embodiment 2

[0045] 1. Preparation of PCL polycaprolactone composite film:

[0046] (1) Take 15 grams of polycaprolactone raw material as a 3D printing material.

[0047] (2) First establish a geometric model through computer modeling software: design a planar network structure with holes, the diameter of the holes is 200 microns, and the thickness is 2 mm, and finally generate an STL format file.

[0048] (3) Print the solid model: input the STL format file obtained above into the 3D printer, set the printing parameters as required, including the height of the nozzle from the plate, the extrusion speed of the nozzle and the walking path of the nozzle, etc., and then print out the 3D model. That is to obtain a polycaprolactone composite membrane with a thickness of 2 mm and a pore diameter of 200 microns.

[0049] 2. Use the polycaprolactone composite film prepared in the above steps to wrap the bone defect site, and then carry out the distributed tissue engineering bone structure accordi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com