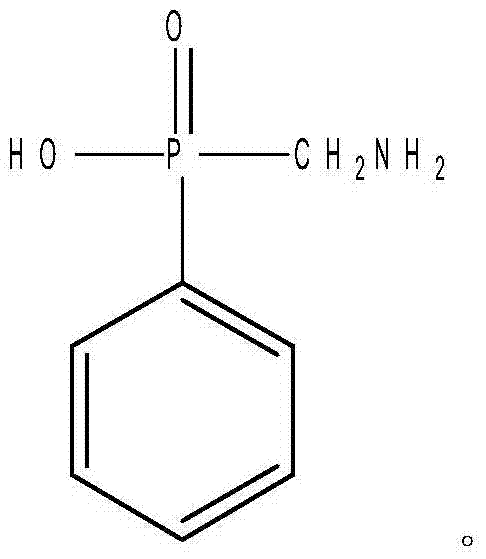

Aminomethyl phenyl phosphinic acid and preparation method thereof

A technology of aminomethylphenylphosphinic acid and chloromethylphenylphosphinic acid, which is applied in the field of aminomethylphenylphosphinic acid and its preparation, can solve the problems of single raw material and oxidation into phosphoric acid, and achieve production The process is simple, the amount of addition is small, and the effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

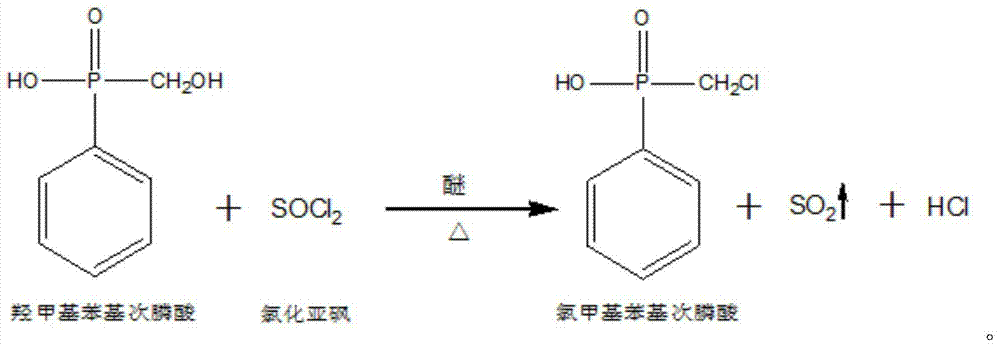

[0030] A preparation method of aminomethylphenylphosphinic acid, the synthesis steps are:

[0031] Heat and react hydroxymethylphenylphosphinic acid, thionyl chloride and anisole in a reaction kettle with a molar ratio of 1:1:3, the temperature of the heating reaction is 40°C, the reaction time is 3 hours, and the reaction ends Cool down to 20 DEG C and filter to obtain chloromethylphenylphosphinic acid crystals afterward, and the filter paper used for filtering is a qualitative filter paper with a pore size of 30 to 120 microns;

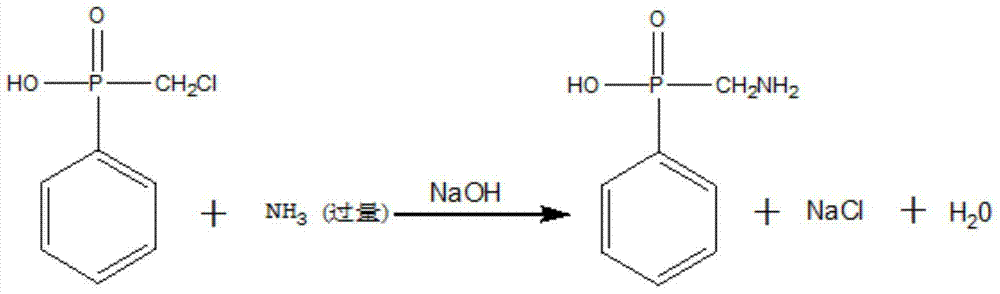

[0032] Chloromethylphenylphosphinic acid crystals are added to a sodium hydroxide solution with a concentration of 2wt%, and the molar ratio of sodium hydroxide to chloromethylphenylphosphinic acid is 1:1, and ammonia gas, ammonia gas When adding, the reaction pressure is 0.1MPa, and then filter again after reacting for 1 hour. The filter paper used for filtering is a qualitative filter paper with a pore size of 30-120 microns, and is washed with wa...

Embodiment 2

[0034] A preparation method of aminomethylphenylphosphinic acid, the synthesis steps are:

[0035] Heat and react hydroxymethylphenylphosphinic acid, thionyl chloride and diphenyl ether in a reaction kettle with a molar ratio of 1:1:10, the temperature of the heating reaction is 80°C, the reaction time is 6 hours, and the reaction ends Cool down to 30 DEG C and filter to obtain chloromethylphenylphosphinic acid crystals afterward, and the filter paper used for filtering is a qualitative filter paper with a pore size of 30 to 120 microns;

[0036] Chloromethylphenylphosphinic acid crystals are added to a concentration of 50wt% sodium hydroxide solution, the molar ratio of sodium hydroxide to chloromethylphenylphosphinic acid is 1.1:1, feed ammonia, ammonia When adding, the reaction pressure is 0.5MPa, and then filter again after reacting for 8 hours. The filter paper used for filtering is qualitative filter paper with a pore size of 30-120 microns, and is washed with water for ...

Embodiment 3

[0038] A preparation method of aminomethylphenylphosphinic acid, the synthesis steps are:

[0039] The hydroxymethylphenylphosphinic acid, thionyl chloride and chloromethyl ether with a molar ratio of 1:1:5 are heated and reacted in a reaction kettle, the temperature of the heated reaction is 50°C, and the reaction time is 5 hours. After the end, cool down to 25°C and filter to obtain chloromethylphenylphosphinic acid crystals. The filter paper used for filtering is a qualitative filter paper with a pore size of 30 to 120 microns;

[0040]Chloromethylphenylphosphinic acid crystals are added to a concentration of 5wt% sodium hydroxide solution, the mol ratio of sodium hydroxide to chloromethylphenylphosphinic acid is 1.2:1, feed ammonia, ammonia When adding, the reaction pressure is 0.3MPa, and then filter again after reacting for 3 hours. The filter paper used for filtering is qualitative filter paper with a pore size of 30-120 microns, and is washed with water for 5 times unt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com