Preparation and application of copper and zinc acrylate compound self-polishing anti-pollution resin

An antifouling resin, copper acrylate technology, applied in antifouling/underwater coatings, coatings, paints containing biocides, etc. problem, to achieve the effect of complete reaction, excellent antifouling effect, and complete dehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

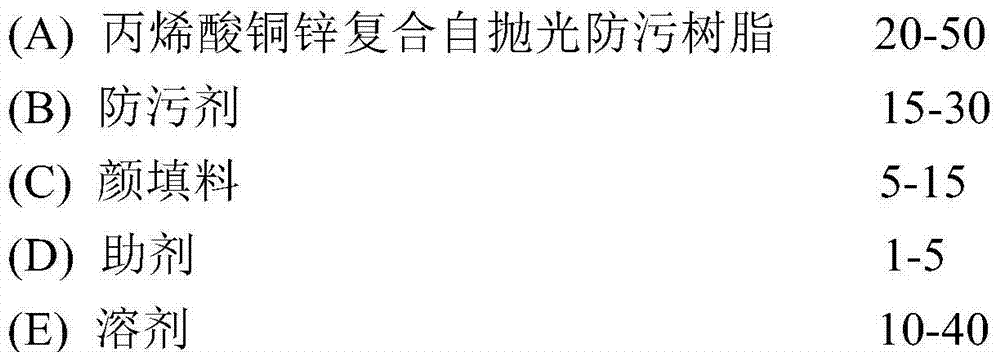

Method used

Image

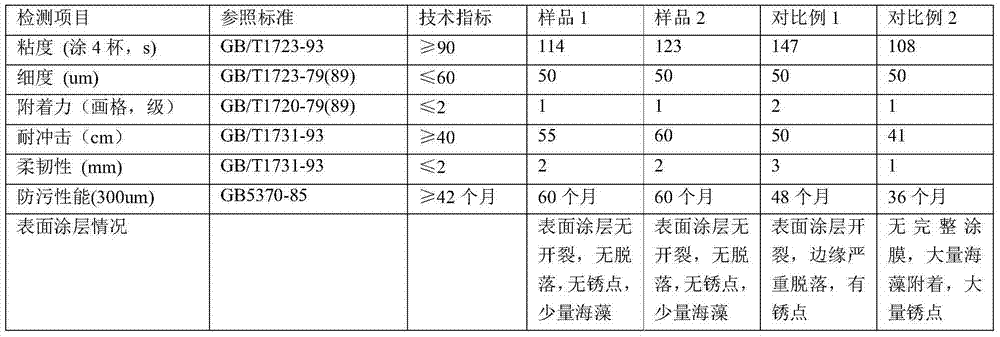

Examples

Embodiment 1

[0034] Synthesis of No. 1 Copper-Zinc Polyacrylate Resin

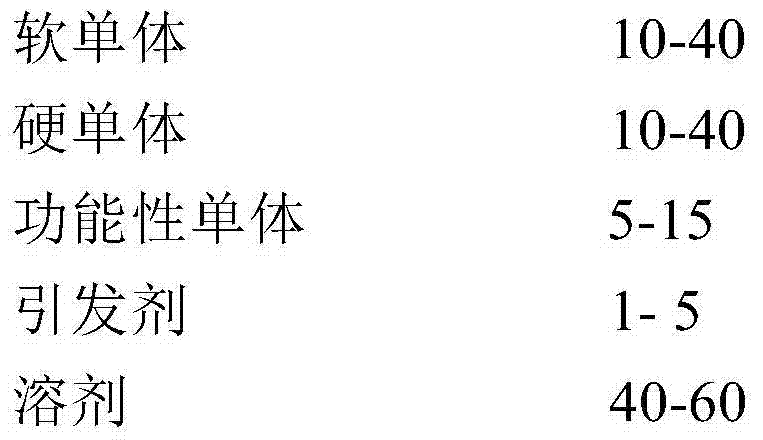

[0035] raw material

[0036] Acrylic acid prepolymer 50g, acrylic acid content is 5% (weight part), mass ratio is the mixed solution 20g of dimethylbenzene and n-butanol of 4:1, basic copper zinc benzoate compound (basic zinc benzoate and Basic copper benzoate is mixed according to the molar ratio of 1:1). Adopt the mode of basic copper-zinc benzoate compound feeding three times, according to equimolar charging ratio (acrylic acid and basic copper-zinc benzoate compound equimolar reaction), add basic copper-zinc benzoate total mass for the first time 1 / 2, react at 80°C for half an hour, add 1 / 4 of the total mass for the second time, react at 80°C for 1 hour, add 1 / 4 of the total mass for the third time, react at 90°C for 1 hour, heat up to 125°C for dehydration, A light blue transparent acrylic copper zinc resin was obtained.

Embodiment 2

[0038] Synthesis of No. 2 Copper-Zinc Polyacrylate Resin

[0039] raw material

[0040] Acrylic acid prepolymer 50g, acrylic acid content is 7% (weight part), mass ratio is the mixed solution 25g of xylene and butyl acetate of 4:1, basic copper zinc benzoate compound (basic zinc benzoate and Basic copper benzoate is mixed according to the molar ratio of 1:1). Adopt the mode of basic copper-zinc benzoate compound feeding three times, according to equimolar charging ratio (acrylic acid and basic copper-zinc benzoate compound equimolar reaction), add basic copper-zinc benzoate total mass for the first time 1 / 2, react at 80°C for half an hour, add 1 / 4 of the total mass for the second time, react at 80°C for 1 hour, add 1 / 4 of the total mass for the third time, react at 90°C for 1 hour, heat up to 125°C for dehydration, A light blue transparent acrylic copper zinc resin was obtained.

Embodiment 3

[0042] raw material

[0043] Acrylic acid prepolymer 50g, acrylic acid content is 5% (weight part), mass ratio is the mixed solution 20g of dimethylbenzene and n-butanol of 4:1, basic copper zinc benzoate compound (basic zinc benzoate and Basic copper benzoate is mixed according to the molar ratio of 1:2), adopts the mode of feeding three times of basic copper-zinc benzoate complex, according to equimolar feed ratio (acrylic acid and basic benzoic acid copper-zinc complex equimolar reaction), the first Add 1 / 2 of the total mass of the basic copper-zinc benzoate complex once, react at 80 degrees for half an hour, add 1 / 4 of the total mass for the second time, react at 80 degrees for 1 hour, and add 1 / 4 of the total mass for the third time 4. React at 90°C for 1 hour, heat up to 125°C for dehydration, and obtain light blue transparent acrylic copper-zinc resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com