Growth method of induction furnace planar-interface large-sized neodymium-doped yttrium aluminium garnet crystal

A technology of crystal growth and Nd-doped yttrium aluminum, applied in crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of high capital occupation rate and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the purpose of the present invention and the advantages of the technical solution more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and examples.

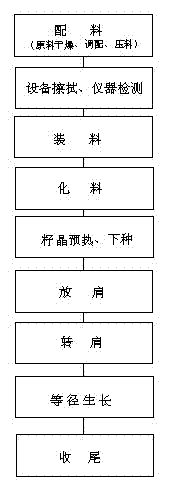

[0023] combine figure 1 (Flow chart of the crystal growth method of the present invention), a large-size neodymium-doped yttrium aluminum garnet crystal growth method at the interface of an induction furnace, including the following processes:

[0024] Step 1. Ingredients: (1) Drying of raw materials: 1000~1200°C for 3~4 hours to remove moisture and some impurities, (2) Raw material Y 2 o 3 、Nd 2 o 3 、Al 2 o 3 According to the ratio of Nd:YAG crystal, (3) pressing: put the raw material into a latex bag and compact it in a cold isostatic press. The volume is so compressed that it can be put into an iridium crucible.

[0025] The diameter of the iridium crucible used is 120-180 mm. In this embodiment, the diameter of the iridium cruc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com