Sterilization process of food packaging paper

A technology of food packaging paper and technology, which is applied in the field of sterilization technology of food packaging paper, can solve the problems of inability to kill all bacteria colonies effectively, short sterilization period of fungicides, easy resistance of pathogenic bacteria, etc., and achieve good economic benefits and ecology Benefits, good bactericidal and antibacterial effects, and improved control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Add RX9100 antibacterial agent in the spray starch preparation tank, the dosage is 2240ml / day, add XD3899 fungicide and RX9100 antibacterial agent in the spray starch storage tank, the dosage of XD3899 is 1500ml / day, and the dosage of RX9100 is 1200ml / day. Add XD3899 fungicide to the spray starch feeding tank, the dosage is 2500ml / day, add in three times, once every 8 hours, add RX9100 fungicide to the cationic starch preparation tank, and add XD3899 fungicide to the cationic starch feeding tank.

[0031] The bactericide adopts the intermittent addition method, and after being put in stably for one week, it is detected five minutes before the addition, and the bacterial content in the spray starch storage tank is 0 ~ 100cfu / mL, which is far less than that of the comparative example, indicating that the bactericidal process of the present invention has Excellent bactericidal and bacteriostatic effect.

Embodiment 2

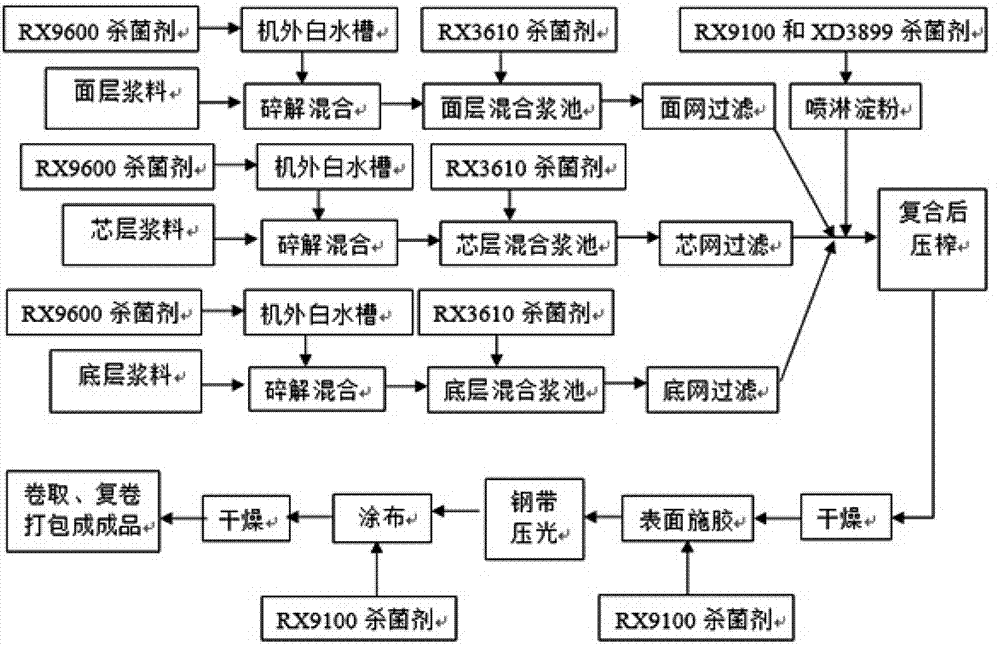

[0033] Such as figure 1 As shown, add RX9600 fungicide to the outer white water tank of the surface machine, the outer white water tank of the bottom machine, and the outer white water tank of the core machine, and add RX3610 fungicide to the surface layer mixing tank, bottom mixing tank, and core layer mixing tank , add RX9100 antibacterial agent in the spray starch preparation tank, the dosage is 2000ml / day, add XD3899 fungicide and RX9100 antibacterial agent in the spray starch storage tank, the dosage of XD3899 is 1200ml / day, and the dosage of RX9100 is 1000ml / day, Add XD3899 fungicide to the spray starch feed tank, the dosage is 2300ml / day, add in three times, add once every 8 hours, add RX9100 fungicide to the cationic starch preparation tank, add XD3899 fungicide to the cationic starch feed tank, Add RX9100 fungicide when sizing and coating the surface.

[0034] The bactericide adopts the intermittent addition method, and after being put in stably for one week, it is d...

Embodiment 3

[0036] Add RX9100 antibacterial agent in the spray starch preparation tank, the dosage is 2500ml / day, add XD3899 fungicide and RX9100 antibacterial agent in the spray starch storage tank, the dosage of XD3899 is 1600ml / day, and the dosage of RX9100 is 1200ml / day. Add XD3899 fungicide to the spray starch feed tank, the dosage is 2600ml / day, add in three times, once every 8 hours, add RX9100 fungicide to the cationic starch preparation tank, add XD3899 fungicide to the cationic starch feed tank, Add RX9100 antibacterial agent to the surface application-coating starch system.

[0037] The bactericide adopts the intermittent addition method, and after being put in stably for one week, it is detected five minutes before the addition, and the bacterial content in the spray starch storage tank is 0 ~ 100cfu / mL, which is far less than that of the comparative example, indicating that the bactericidal process of the present invention has Excellent bactericidal and bacteriostatic effect....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com